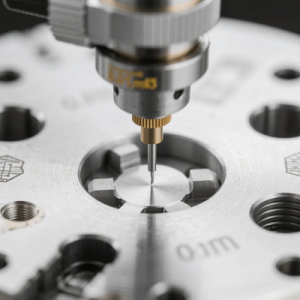

In today’s era of miniaturization and high-performance demands, precision is no longer optional but essential. When manufacturing requires extremely tight accuracy, high-precision CNC machining becomes the standard in demanding industries.

This level of precision control means that machining errors must be kept within an extremely small range of 0.02mm — which is critical for the functional stability of many parts.

But in practice, what exactly does ±0.01mm CNC machining mean — and how do you know when it’s the right choice?

Why Is ±0.01mm Tolerance Important?

Tolerance refers to the acceptable deviation range from the specified dimensions of a part. In strict CNC machining, ±0.01 millimeters is considered ultra-precision. Typically, factories must have:

Ultra-rigid CNC machines (often 5-axis)

Temperature-controlled workshops

Micron-level toolpath programming

Advanced fixtures and inspection processes

Even the smallest errors can cause misalignment, friction, or failure in parts — so high-precision CNC parts become indispensable. In industries where micron-level deviations may cause functional issues, there is no room for compromise. This is why many customers choose tight tolerance CNC machining — because even micron-level errors can affect product performance.

Common Applications of High-Precision CNC Parts

The demand for CNC machining with accuracy up to ±0.01mm is growing rapidly. Let’s look at some typical cases:

Medical parts and instruments

Even a 0.02mm deviation can lead to implant failure or improper surgical tools. In many medical CNC machining projects, clients require extremely tight dimensional control, often at ±0.01mm precision.

Aerospace engine components

Parts with strict tolerances are essential to maintain reliability at high altitudes and extreme temperatures.

Micro-mechanical components

Wearables, connectors, and sensor housings rely on CNC machining to produce precisely fitting and aligned small metal parts.

Challenges in Achieving ±0.01mm CNC Machining

Achieving ±0.01mm tolerance in CNC machining increases costs, extends production time, and usually requires multiple inspection stages. To maintain this level of precision, factories need:

Calibrated CMM (Coordinate Measuring Machine) inspection tools

Stable environmental controls

Skilled technicians and process engineers

For customers who cannot tolerate dimensional errors, these challenges are worthwhile — especially when manufacturing CNC products with strict tolerances in regulated industries. Such micron-level CNC machining projects demand higher standards in equipment condition, fixture accuracy, toolpath planning, and even temperature and humidity control.

In other words, ±0.01mm machining reflects the comprehensive strength of the manufacturing facility.

How to Specify ±0.01mm in Your Design

Not all parts require ultra-tight tolerances. Unless your part demands extremely high precision for its function, ±0.01mm CNC machining should be used selectively, as tighter tolerances significantly increase cost.

Tip: When requesting our precision CNC machining services, please provide 2D drawings with clear GD&T symbols and tolerance zones. This helps your supplier assess manufacturability and cost trade-offs accurately.

Final Thoughts

In today’s world of product miniaturization and performance-driven design, high-precision CNC parts are no longer a luxury but a necessity. Whether you need to manufacture surgical instruments, aerospace brackets, or high-tech housings, CNC machining of small metal parts with ±0.01mm tolerance is key to success.

We specialize in high precision CNC machining and tight tolerance CNC parts production control, ensuring consistent accuracy from prototype to mass production.

If you need a partner that can provide reliable, repeatable, and scalable precision CNC machining with tolerances from ±0.05mm down to ±0.01mm, Jeek is here to help. If you have parts to manufacture, feel free to contact us for an evaluation of your drawings or requirements. We will provide you with professional advice and transparent quotations promptly.

More recommendations

Tight tolerance machining is critical, and many of these requirements are verified during CNC prototyping before committing to production tooling.