In modern CNC machining, machining centers play a central role in producing complex parts efficiently. However, the term is often used loosely and can be confused with standard CNC milling machines.

This article explains what a CNC machining center is, outlines its key characteristics, and describes the common types used in manufacturing today.

What Is a CNC Machining Center?

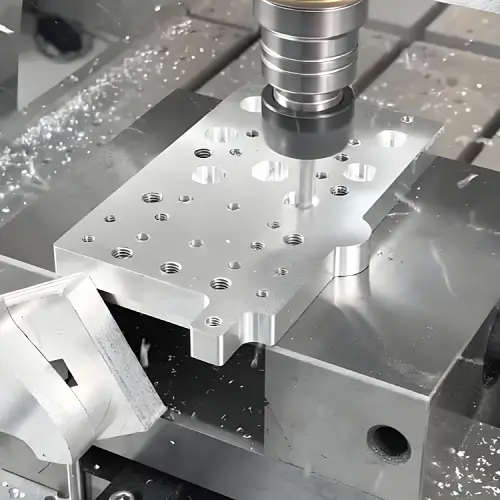

In modern manufacturing, a CNC machining center is a computer-controlled machine tool used to perform multiple milling operations within a single setup. Unlike basic CNC milling machines, machining centers are equipped with automatic tool changers and tool magazines, which allow different cutting tools to be selected and used during one continuous program.

Because tools can be changed automatically, a CNC machining center can complete several machining steps without stopping for manual intervention. Operations such as milling, drilling, tapping, and boring are often carried out sequentially while the workpiece remains fixed in position.

In production environments, CNC machining centers are commonly used when parts require consistent positional accuracy between features or when multiple operations need to be completed efficiently in one setup.

Key Characteristics of a CNC Machining Center

Several characteristics define a CNC machining center and explain why it is widely used in modern machining.

An automatic tool changer allows cutting tools to be exchanged automatically during machining. Tools are stored in a tool magazine, enabling complex machining sequences to run without operator involvement.

Most machining centers operate with multi-axis CNC control, typically three linear axes, with optional rotary or tilting axes on more advanced machines. Together, these features support stable, repeatable machining rather than single-operation work.

Main Components of a CNC Machining Center

Spindle System

The spindle system drives the cutting tool and has a direct influence on machining stability. In a machining center, stiffness and thermal behavior matter more than peak speed, especially during long programs.

Automatic Tool Changer (ATC)

The automatic tool changer allows tools to be exchanged automatically while the program is running. Without an ATC, a machine may still mill accurately, but it does not function as a true machining center in production.

Tool Magazine

The tool magazine stores the cutting tools used during machining and supplies them to the ATC when needed. As part complexity increases, tool capacity often becomes more important than expected.

CNC Control System

The CNC control system coordinates axis motion, spindle behavior, tool selection, and program execution. It ensures that tool changes and movement sequences remain synchronized throughout the machining cycle.

Coolant and Chip Removal System

Coolant delivery and chip removal are often overlooked until problems appear. Poor chip evacuation can lead to recutting, surface damage, and unstable cutting conditions.

Common Types of CNC Machining Centers

CNC machining centers are commonly classified by spindle orientation and axis configuration.

Vertical Machining Center (VMC)

A vertical machining center uses a vertically oriented spindle, with cutting tools approaching the workpiece from above. This configuration is widely used for general-purpose machining tasks such as face milling, drilling, tapping, and pocket machining.

Horizontal Machining Center (HMC)

A horizontal machining center features a horizontally mounted spindle. This layout is often used for parts that require machining on multiple faces and benefit from improved chip evacuation.

Multi-Axis Machining Centers

Multi-axis machining centers add rotary or tilting axes to standard three-axis motion. Most CNC machining centers operate with X, Y, and Z axes, while advanced systems include additional axes for angled features or complex surfaces.

Common Machining Operations Performed on a Machining Center

Milling

Milling is the primary material-removal process on a machining center and accounts for most of the cutting work in a typical program.

Drilling

Drilling is usually performed to create initial holes before tapping or boring, with accuracy relying more on positioning than cutting speed.

Tapping

Tapping forms internal threads directly on the machine.

Boring

Boring is applied when tighter hole size or alignment is required after drilling.

CNC Machining Center vs CNC Milling Machine

The difference between a CNC machining center and a CNC milling machine lies mainly in automation and workflow.

Basic CNC milling machines often require manual tool changes and are typically used for individual machining steps. CNC machining centers are designed to complete multiple operations automatically using different tools within a single program.

In many cases, a basic milling machine is used to perform one operation at a time, while a machining center is capable of running several operations in sequence and producing a finished part in one setup.

Typical Applications of CNC Machining Centers

Multiple holes or pockets with precise positional relationships

Some parts care more about where features are relative to each other than about the exact size of a single hole. Keeping those features in the same setup avoids small alignment shifts that are hard to correct later.

This is a common situation where a machining center makes practical sense.

Machined features on more than one face

Not all parts can be finished from one direction. When features appear on different faces, removing and re-clamping quickly becomes a source of error.

A machining center reduces how often that needs to happen.

Consistent tolerances across repeat production runs

Hitting a tolerance once does not prove much. The challenge shows up when the same tolerance must be held day after day, across multiple batches.

Machining centers are often chosen for this kind of process stability.

Reduced setup changes during machining

Every setup adds variation. Fewer setups usually mean fewer surprises.

As part geometry becomes more complicated, this advantage becomes easier to see.

CNC machining centers are widely used in aerospace, automotive, industrial equipment, and general manufacturing. In these fields, machining centers are selected for their ability to maintain positional accuracy across multiple features rather than for any single cutting operation.

Conclusion

A CNC machining center is best understood as a production-focused CNC machine rather than a single-purpose milling tool. Its primary role is to complete multiple machining operations within one setup while maintaining consistent positional accuracy between features.

By combining automatic tool changing, multi-axis control, and stable process execution, machining centers help reduce setup-related variation and support repeatable results across production runs. In modern manufacturing, they are chosen not for one specific cutting operation, but for their ability to manage an entire machining sequence efficiently and reliably.

FAQs

Is a CNC machining center the same as a CNC milling machine?

No. While both are used for milling operations, a CNC machining center is designed to perform multiple operations automatically within one setup, whereas basic CNC milling machines are often used for individual machining steps.

Do CNC machining centers always produce a finished part in one setup?

Not always. Many parts can be completed in a single setup on a machining center, but complex parts may still require secondary operations depending on design and tolerance requirements.

What is the main advantage of using a CNC machining center?

The primary advantage is process consistency. Machining centers reduce setup changes and help maintain positional accuracy between features across repeated production runs.

Are CNC machining centers only used in large-scale production?

No. They are used in both low-volume and production environments whenever parts require multiple operations and stable, repeatable results.