Ultra-high molecular weight polyethylene (UHMWPE) is an engineering plastic with extremely high molecular weight, usually between 2 million and 6 million. Due to its special molecular structure, UHMWPE has excellent wear resistance, low coefficient of friction, high impact resistance and excellent chemical stability, and is widely used in many demanding industrial fields. With the continuous development of material science and technology, the application scenarios of UHMWPE are becoming more extensive, especially in the mining, medical, aerospace, protective equipment and food processing industries.

Against this backdrop, and with the rising demand for high-performance materials, Jeek Rapid employs highly efficient processing technologies, such as extrusion molding, injection molding, and CNC machining, to provide customers with precise, customized solutions. This article provides an in-depth analysis of the properties and applications of ultra-high molecular weight polyethylene (UHMWPE) and how it can be precision machined to meet the demands of modern industrial production.

What is UHMWPE?

Ultra High Molecular Weight Polyethylene (UHMWPE) is itself a polyethylene material, except that its molecular weight, usually between 2 and 6 million, far exceeds that of ordinary polyethylene. The high molecular weight directly attributes to UHMWPE’s many excellent properties, allowing it to excel in many industrial applications. Its long, densely arranged molecular chains make the material extremely resistant to abrasion and impact in friction and impact environments.

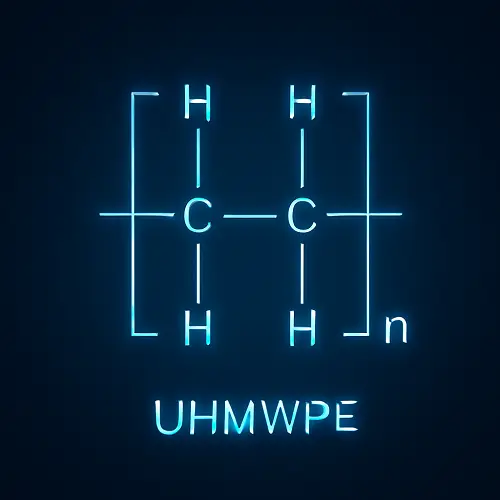

Chemical formula of UHMWPE

The chemical formula for Ultra High Molecular Weight Polyethylene (UHMWPE) is based on the molecular structure of ordinary polyethylene (PE), where the basic unit is the ethylene monomer. Its chemical formula is usually written:

(C₂H₄)n

C₂H₄ represents the ethylene monomer (i.e., each unit consists of two carbon atoms and four hydrogen atoms).

n represents the number of repeating units of polymerization and refers to the length of the chain of carbon atoms in the polymer, between 2 and 6 million.

UHMWPE has the same chemical formula as regular polyethylene (PE), but its molecular weight is considerably higher, which gives it excellent physical properties such as abrasion resistance, low friction and high impact resistance.

Properties of UHMWPE

Extremely high abrasion resistance

UHMWPE produces little to no wear in prolonged friction environments, making it an ideal wear-resistant material.

Low coefficient of friction

UHMWPE has a low coefficient of friction (approximately 0.04 to 0.10), which reduces friction loss between sliding parts and improves efficiency.

Excellent Impact Resistance

In low temperature and high impact environments, UHMWPE still maintains good toughness and is not easy to break.

Excellent chemical stability

Strong corrosion resistance to most chemicals such as acids, alkalis and solvents.

Good low temperature performance

Even at very low temperatures, UHMWPE maintains good toughness and strength and avoids brittle cracking.

Comparison with PE, LDPE and HDPE Polyethylene Materials

Among the materials used in industrial manufacturing, there are usually different types of polyethylene materials, commonly including low-density polyethylene (LDPE), high-density polyethylene (HDPE) and ultra-high molecular weight polyethylene (UHMWPE). All three materials belong to the polyethylene family, but there are significant differences in performance and application areas in contrast.

Low Density Polyethylene (LDPE)

Commonly used in film and packaging, LDPE has good flexibility and transparency. It has a looser molecular chain and is more plastic, making it suitable for some low-strength applications. LDPE’s lower strength and abrasion resistance compared to UHMWPE limits its use in environments where high strength and abrasion resistance are required.

High Density Polyethylene (HDPE)

With its higher density and greater tensile strength, HDPE is widely used in pipes, containers and plastic products. Although HDPE has higher tensile strength, it is still inferior to UHMWPE in terms of abrasion resistance and low friction properties, especially in environments where it is required to withstand very high friction and impact.

Ultra High Molecular Weight Polyethylene (UHMWPE)

UHMWPE has outstanding abrasion and impact resistance, chemical stability and low coefficient of friction compared to LDPE and HDPE. It is particularly suitable for applications that are subject to extremely high friction, impact, chemical attack and low temperature environments, such as in the mining industry, medical devices and protective equipment.

UHMWPE in Industrial Applications

With its excellent performance, ultra-high molecular weight polyethylene (UHMWPE) has been gradually increasing its application in several industrial fields, especially in high load and extreme environments, and the following are the main application areas:

Conveying systems and mechanical components

In the mining, metallurgical and chemical industries, UHMWPE is commonly used in the production of conveyor belts, slides, gaskets and other components. Its excellent abrasion resistance, low coefficient of friction and resistance to high loads enable the material to maintain excellent performance after a long period of work, reducing equipment maintenance costs.

Medical Devices

In the medical industry, especially in the field of artificial joints (e.g. knee joints, hip joints), UHMWPE is an ideal material due to its excellent wear resistance and biocompatibility. By reducing wear and prolonging the life of the prosthesis, the use of UHMWPE in the field of replacement joints is becoming more and more popular.

Protective equipment

UHMWPE is widely used in the military and security industries, especially in protective equipment such as bulletproof vests, helmets and shields. Its high strength and lightweight properties enable it to provide excellent protective performance while reducing the weight of the equipment and improving comfort.

Food processing and packaging

In the food industry, UHMWPE is widely used in conveyor chains, rollers and food processing equipment due to its corrosion and abrasion resistance. It is non-toxic, odorless and meets hygiene standards to ensure the safety of the process.

Marine and Ship Engineering

Due to its good water resistance and wear resistance, UHMWPE is widely used in marine engineering and ships. It is used as harbor loading and unloading equipment, ship taxiing devices, etc. to reduce friction and improve efficiency.

Jeek Rapid’s Processing Technology for UHMWPE

To ensure that UHMWPE can be efficiently used for different industrial needs, Jeek Rapid employs advanced and efficient processing technologies such as extrusion, injection molding and CNC machining. These technologies are analyzed in detail below:

1. Extrusion: Efficient production of large-size components

Extrusion molding technology is suitable for the production of long strips, tubes and sheets. In this process, UHMWPE pellets are heated to a molten state and extruded through a die to produce the desired shape of the product. Jeek Rapid uses state-of-the-art extrusion equipment that allows for precise dimensional control and produces abrasion-resistant, high-precision products.

Benefits:

-

Efficient mass production capabilities.

-

Ideal for products that require large dimensions and high strength, such as pipes, plates, slides, etc.

2. Injection Molding: Precision Parts Production

Injection molding is suitable for the production of small precision parts, especially for products with complex shapes and sizes. By optimizing the injection molding process, Jeek Rapid is able to efficiently convert UHMWPE into fine industrial parts such as medical device fittings, gears and seals.

The Benefits:

-

High precision and complex shape manufacturing.

-

Suitable for small to medium volume production.

3. CNC Machining: Precision machining of complex parts

Jeek Rapid’s CNC machining technology allows molded UHMWPE parts to be precisely machined to exacting dimensional tolerances and surface finishes. Whether it’s turning, milling or drilling, CNC technology provides customers with high-precision machining.

Advantages:

-

Suitable for the manufacture of complex parts with high precision.

-

Can meet tight tolerances and surface finish requirements.

Benefits of Choosing Jeek Rapid

As an industry-leading precision machining company, Jeek Rapid is committed to providing customers with efficient and accurate machining solutions. We provide high-quality UHMWPE parts for a variety of industries through extrusion, injection molding and CNC machining technologies, ensuring that every product meets customer needs and industry standards.

Quality Service and Customized Solutions

Jeek Rapid offers customized production solutions to ensure high quality machining within efficient production cycles. Our team of experts will optimize each process according to the customer’s needs to ensure the best performance of the product. Click to upload your CAD and get a quote, we will get back to you within 24 hours!