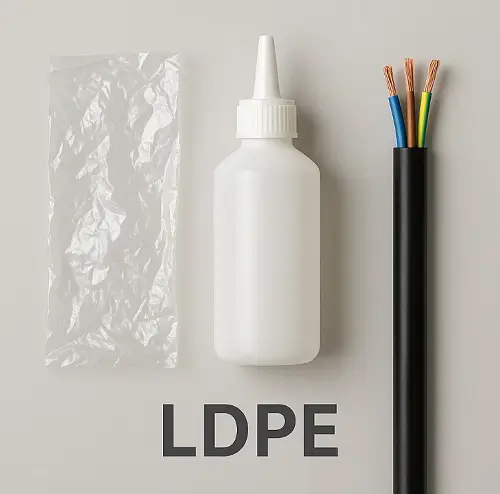

Polyethylene is, without a doubt, the workhorse of the plastics world. But not all PE is created equal—different grades boast vastly different properties, which in turn dictate their applications. Take Low-density Polyethylene (LDPE): its excellent flexibility, solid clarity, and ease of processing make it a go-to material for everything from packaging films and wire insulation to everyday containers. For anyone specifying materials, getting a handle on LDPE’s properties, processing behavior, and how it stacks up against other polyethylenes like HDPE is key to making the right call.

So, what makes LDPE tick? It’s a thermoplastic characterized by a highly branched molecular structure. These branches prevent the chains from packing together tightly, resulting in low crystallinity. This is precisely what gives LDPE its trademark toughness, translucency, and softness. While it can’t match the strength or heat resistance of HDPE, LDPE’s unbeatable combination of processability and all-around performance keeps it firmly in the game for packaging films and flexible products.

What is Low-Density Polyethylene (LDPE)?

Low density polyethylene (LDPE) is a very common thermoplastic material in the polyethylene family. Its molecular structure contains a high number of branched chains and a low degree of crystallinity, which allows LDPE to excel in toughness, transparency and flexibility. Although not as strong or heat resistant as High Density Polyethylene (HDPE), LDPE is widely used in packaging, films and all types of flexible products due to its good processing suitability and overall performance.

How is LDPE produced?

LDPE is usually produced by high pressure free radical polymerization. At high pressures and temperatures of 1000 to 3000 bar, ethylene monomers are polymerized under the action of a free radical initiator, such as a peroxide, to form a polyethylene molecule with a large number of branched chains. This branched structure makes the molecular chains less tightly arranged, resulting in a material characterized by low density and low crystallinity. After the polymerization reaction is complete, the resulting resin is pelletized and then extruded, blow molded, injection molded, or thermoformed to make the final product.

Main performance parameters of LDPE

The density of LDPE is generally between 0.91–0.93 g/cm³, which belongs to the lighter plastic varieties and helps to reduce the weight of products. Its tensile strength is usually in the range of 8–15 MPa, which belongs to the medium-low level, but the elongation at break can be up to 300%–600%, showing high ductility. The bending modulus is about 150–300 MPa, indicating that the material is less rigid and softer. The melting temperature of LDPE ranges from 105–115°C, and the heat distortion temperature is not high, about 50°C, so the long-term use temperature is limited. In addition, LDPE has a very low water absorption (<0.01%) and is largely unaffected by humidity.

It should be noted that the above values are typical ranges, and the performance of different grades or modified LDPE will vary.

Typical property table:

| Property | Typical Range |

|---|---|

| Density (g/cm³) | 0.91 – 0.93 |

| Tensile Strength (MPa) | 8 – 15 |

| Flexural Modulus (MPa) | 150 – 300 |

| Elongation at Break (%) | 300 – 600 |

| Melting Point (°C) | 105 – 115 |

| Heat Deflection Temp (°C) | ~50 |

| Water Absorption (%) | <0.01 |

Advantages and Limitations of LDPE

Advantages:

-

Excellent flexibility, able to withstand large deformations without rupture

-

Lightweight and easy to transport and install

-

Good chemical stability, can withstand a variety of acids, alkalis and general solvents

-

Excellent electrical insulation properties, commonly used in wire and cable insulation

-

Almost non-absorbent, unaffected by humidity

-

Good processing adaptability, suitable for injection molding, blow molding, extrusion and thermoforming

Limitations include:

-

Poor heat resistance, long-term use temperature should not exceed ~50°C

-

Low rigidity and strength, not suitable for high load structural parts

-

Dimensional stability is poor, prone to thermal expansion or contraction

-

Low surface energy, difficult to print or bond directly, often requires surface treatment

Common applications for LDPE

Thanks to its flexibility, lightweight and good processability, LDPE is widely used in many fields:

- Packaging films: shopping bags, cling films, shrink films

-

Flexible containers: squeeze bottles, ointment tubes, flexible lids

-

Wire and cable insulation: insulation layers and sheathing

-

Daily necessities and medical supplies: wash bottles, toys, disposable products

-

Construction and engineering: moisture-proof films, geomembranes, protective films

Differences between LDPE and other polyethylene materials

Within the polyethylene family, LDPE differs significantly from other grades such as HDPE, LLDPE and UHMWPE:

-

LDPE vs HDPE: LDPE has more branched chains, lower crystallinity, and is softer and more transparent. HDPE has linear molecular chains, higher rigidity and strength, and is better suited for rigid containers and structural parts.

-

LDPE vs LLDPE: LLDPE has a linear molecular structure with short branches, providing better tear and puncture resistance at similar densities, often used for high-performance films.

-

LDPE vs UHMWPE: UHMWPE has an ultra-high molecular weight, excellent wear and impact resistance, and is mainly used for wear-resistant parts, bearings and demanding mechanical components.

FAQs

What is the melting point of LDPE?

Typically 105–115°C, depending on the grade.

Is food grade LDPE safe?

Yes. Food grade LDPE that meets FDA or EU standards is safe for use in food packaging and containers.

Can LDPE be CNC machined?

Yes, but machining requires sharp tools, lower cutting speeds and effective cooling to avoid softening and burrs.

Which is more suitable for film, LDPE or HDPE?

LDPE is softer and more ductile, suitable for general films. HDPE films are stiffer and stronger, often used for packaging bags and handbags.

Can LDPE be recycled?

Yes. LDPE can be recycled into films, pipes and other products, although its mechanical properties may be lower than virgin material.

About JeekRapid

At JeekRapid, we provide CNC machining, injection molding, blow molding, and thermoforming services for LDPE, HDPE and other engineering plastics. From prototypes to production runs, our team helps engineers select the right material and process for their applications, ensuring precision, consistency and cost efficiency.