High-Density Polyethylene (HDPE) is one of the most widely used thermoplastic polymers in the world. HDPE belongs to the polyethylene family and is widely recognized for the strength, durability, and chemical resistance after processing. Engineers rely on HDPE for a wide range of applications including pipelines, chemical containers, packaging films, and CNC-machined parts. Its cost-effectiveness and versatility make it indispensable in industrial and consumer products. This article will explore High-Density Polyethylene (HDPE), introduction, properties, advantages and disadvantages, and applications.

What is High-Density Polyethylene (HDPE)?

High-Density Polyethylene (HDPE) is produced from ethylene monomers under controlled polymerization. The molecular structure is highly linear, with very few side branches, crystallinity up to 70% to 90%, and density between 0.94–0.97 g/cm³. Compared with Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE) has superior stiffness, chemical resistance, and mechanical strength. Within the polyethylene family, HDPE occupies the position of high density and high strength.

With light weight, non-toxicity, impact resistance, and corrosion resistance, HDPE has become one of the most widely used plastics, widely applied in water and gas pipelines, chemical storage tanks, packaging containers, geomembranes, and consumer goods. At the same time, HDPE also has good recyclability, in line with the needs of modern industry for sustainable development.

How is High-Density Polyethylene (HDPE) Produced?

The production of High-Density Polyethylene (HDPE) begins with the steam cracking of hydrocarbons such as petroleum, ethane, or propane from underground, generating ethylene monomers. These monomers, after purification, are sent into polymerization reactors. Under the action of Ziegler–Natta catalysts (this is a type of metal catalyst) or metallocene catalysts, at low pressure (1–50 bar) and moderate temperature (50–80 ℃), ethylene molecules connect to each other to form long chains with very few side branches. Finally forming polymer chains with high density and high crystallinity.

After polymerization, the resin is cooled, pelletized, and delivered to processors. These pellets are then made into final products through extrusion, blow molding, injection molding, rotational molding, or CNC machining. The controlled production process directly determines the mechanical properties, thermal properties, and processing properties of High-Density Polyethylene (HDPE).

Key Properties of High-Density Polyethylene (HDPE)

| Property | Typical Value | Standard Reference |

|---|---|---|

| Density | 0.94–0.97 g/cm³ | ASTM D792 / ISO 1183 |

| Tensile Strength | 20–30 MPa | ASTM D638 / ISO 527 |

| Flexural Modulus | ~1 GPa | ASTM D790 / ISO 178 |

| Izod Impact Strength | 10–20 kJ/m² | ASTM D256 / ISO 180 |

| Heat Deflection Temp | 70–80 ℃ | ASTM D648 / ISO 75 |

| Melting Point | 130–137 ℃ | ASTM D3418 / ISO 11357 |

| Water Absorption | < 0.01 % | ASTM D570 / ISO 62 |

High strength-to-weight ratio

HDPE has a tensile strength of 20–30 MPa and a density of about 0.95 g/cm³, providing strong yet lightweight solutions. For municipal pipelines, structural tanks, and industrial containers this is essential, because these materials must achieve mechanical integrity without increasing weight. Compared with metals, HDPE can reduce handling costs while providing the same service life in many applications.

Excellent chemical resistance

According to ASTM D543 testing, HDPE resists most acids, alkalis, and solvents. Stability makes chemical drums, storage tanks, and process pipelines usually choose HDPE. Maintenance demand is minimized, but strong oxidizers such as nitric acid may cause its degradation, requiring careful selection in extreme environments.

Impact resistance

In notched Izod impact testing (ASTM D256), High-Density Polyethylene (HDPE) typically shows 10–20 kJ/m² toughness and retains ductility at sub-zero temperatures. This makes it suitable for manufacturing fuel tanks, playground equipment, and protective housings, which must withstand sudden mechanical shocks without cracking.

Moisture barrier

According to ASTM D570 standard, the water absorption rate is below 0.01%, ensuring dimensional stability in humid or underwater environments. Geomembranes used in landfills, drainage systems, and marine applications rely on the moisture resistance of HDPE, performance can last for decades.

Electrical insulation

The non-polar structure of HDPE gives it high dielectric strength, making it the preferred material for cable jackets and electrical conduits. Underground and submarine power systems benefit from the insulation of HDPE and its resistance to moisture and soil chemicals.

Surface characteristics

HDPE’s surface energy is about 31–33 dynes/cm, for inks or adhesives adhesion is too low. This is advantageous in non-stick applications such as cutting boards, but in cases where printing or bonding is required it has limitations. Usually corona discharge or flame treatment is used to enhance adhesion performance.

Advantages and Disadvantages of HDPE

Advantages

-

Lightweight yet durable.

-

High chemical and corrosion resistance.

-

Excellent toughness and low-temperature impact performance.

-

Very low water absorption, good weather resistance, and equipped with stabilizers.

-

Cost-effective, supports multiple forming and processing methods.

Disadvantages

-

Limited heat resistance; long-term use is usually below 80 ℃.

-

Shrinkage and dimensional instability in tight-tolerance machining.

-

Low surface energy makes bonding and coating difficult without pretreatment.

-

Mechanical strength and stiffness are lower than engineering plastics such as ABS, PA, or PC.

Applications of HDPE

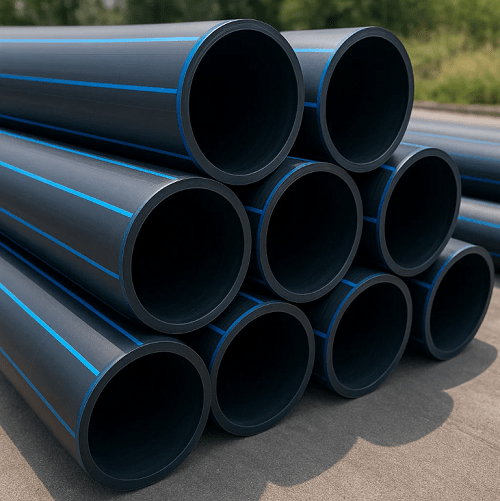

Pipeline systems

HDPE pipes are widely used for water, gas, and chemical transport. Hot-melt welding (as mentioned in the table above) ensures leak-free joints, while corrosion resistance makes their service life far longer than steel pipes. For municipal infrastructure and irrigation systems, HDPE pipes are easier to operate, installation cost lower, first choice.

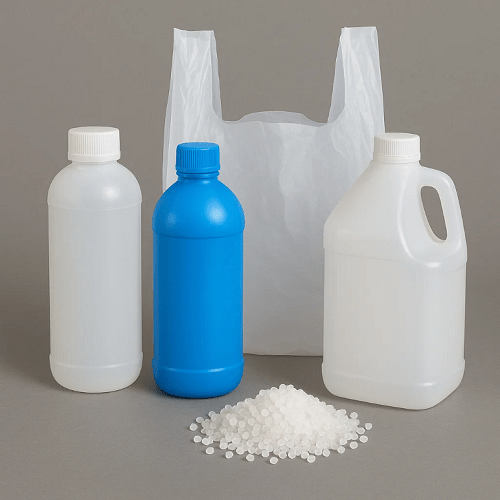

Containers and packaging

HDPE’s impact resistance and chemical stability make it ideal for detergent bottles, food-grade containers, chemical drums, and automotive fuel tanks. Compared with glass or metal, HDPE containers are lighter, safer to handle, and more economical.

Films and sheets

Through extrusion, HDPE can be made into agricultural films, packaging films, and geomembranes. Geomembranes are especially suitable for landfills, mining operations, and reservoirs, forming impermeable barriers, preventing leakage, ensuring environmental safety.

Electrical industry

In cable insulation and conduit systems, High-Density Polyethylene (HDPE) combines dielectric strength, moisture resistance, and UV resistance (with stabilizers). Widely used in underground telecom and power lines.

Consumer products

Toys, household garbage bins, and outdoor furniture are everyday products usually made of High-Density Polyethylene (HDPE). Safety, toughness, and weather resistance ensure their long-term usability in consumer applications.

Machining applications

HDPE sheets and rods are usually CNC-machined into wear plates, cutting boards, and chemical liners. Its low friction coefficient and corrosion resistance make it a practical alternative to metals in non-load-bearing mechanical components, especially in food processing and material handling industries.

Differences between HDPE, LDPE, and Polyethylene

The main difference between HDPE and LDPE lies in molecular structure. The linear structure of HDPE makes its density higher and stiffness greater, making it the preferred material for pipes, containers, and structural products. LDPE has a branched structure, softer and more flexible, more suitable for films, bags, and lightweight packaging.

Polyethylene (PE) is the entire polyethylene family, including High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), and Ultra-High Molecular Weight Polyethylene (UHMWPE). Each type meets different engineering needs: High-Density Polyethylene (HDPE) focuses on strength and chemical resistance, Low-Density Polyethylene (LDPE) focuses on flexibility, Linear Low-Density Polyethylene (LLDPE) focuses on packaging toughness, and Ultra-High Molecular Weight Polyethylene (UHMWPE) focuses on extreme abrasion resistance. These are the differences.

High-Density Polyethylene (HDPE) combines strength, chemical stability, and cost-effectiveness, one of the most important polymers in modern manufacturing. Although we engineers must consider its limited heat resistance and bonding difficulties, HDPE remains the preferred material for infrastructure, consumer goods, packaging, and CNC-machined parts. As a member of the polyethylene family, HDPE has durability unmatched by flexible grades, its position as cornerstone of industrial materials.

FAQ

1. What is the melting point of HDPE?

The melting point of HDPE is usually 130–137 ℃, depending on grade and testing standard (ASTM D3418 / ISO 11357).

2. Is HDPE safe for food contact?

Yes. Food-grade HDPE complies with FDA and EU regulations for packaging and containers. But only certified food-safe grades can be used for direct food contact.

3. How does HDPE compare with PVC in piping materials?

Compared with PVC, HDPE pipes have better impact resistance, chemical resistance, and joint reliability (fusion welding). However, PVC has higher stiffness and better temperature performance.

4. Is recycled HDPE reliable?

Yes, recycled HDPE (rHDPE) is commonly used to make bottles, pipes, and building materials. Compared with virgin grades, its mechanical properties may be slightly reduced, but proper sorting and processing can ensure reliable performance.

5. Why do property values differ between datasheets?

Testing standards (ASTM, ISO, DIN, GB) and resin grades differences cause property values to vary. Property tables should be understood as “typical ranges,” not fixed values.

6. Can HDPE be CNC machined?

Yes. HDPE sheets and rods are usually CNC-machined into parts. Using sharp carbide tools and proper fixturing, machining tolerances can usually reach ±0.02 mm.

About JeekRapid

JeekRapid provides High-Density Polyethylene (HDPE) CNC machining and injection molding services, supporting projects from rapid prototyping to large-scale production. JeekRapid has more than 40 CNC machines, ISO 9001 and ISO 13485 certifications, and experienced engineers to ensure precision and quality.

Upload your CAD files today, our engineering team will review and provide detailed quotation within 24 hours.