In manufacturing, the way a material interacts with light is more than an aesthetic detail—it often dictates design feasibility and production methods. Engineers choosing between transparent, translucent, and opaque materials are not simply deciding how a product will look. They are defining performance in optical clarity, light diffusion, or complete light blocking. These properties determine whether CNC machining, injection molding, or advanced surface finishing will be required.

For example, acrylic sheets transmit over 90% of visible light and are favored for displays, while frosted polycarbonate diffusers soften LED glare in office lighting. Metals and dense plastics provide opacity where structural strength and protection are essential. Understanding how transparency levels affect both design and processing enables engineers to balance cost, function, and manufacturability.

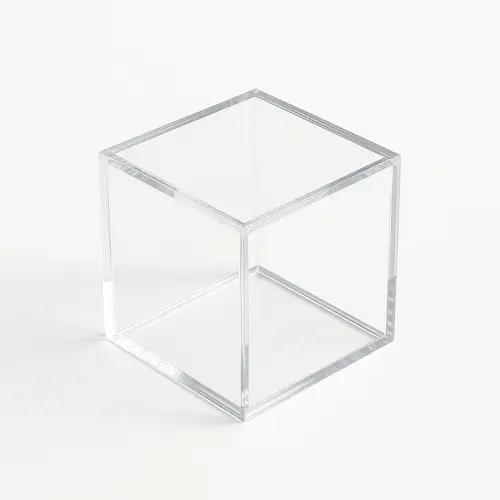

What is Transparent Material?

Transparent materials are defined by their ability to transmit more than 90% of visible light with minimal scattering. Soda-lime glass offers around 90% transmission, acrylic reaches about 92%, and polycarbonate falls in the 88–90% range. While these materials appear equally clear to the eye, their engineering differences are critical. Acrylic is lightweight and optically pure but scratches easily, making it best suited for display covers or packaging. Polycarbonate, though slightly less transparent, delivers up to 250 times the impact resistance of glass, making it indispensable for protective housings and safety shields.

In manufacturing, transparent plastics present unique challenges. CNC machining often leaves tool marks or stress whitening, requiring flame or vapor polishing to restore optical clarity. For injection molding, molds must be mirror-polished since even microscopic scratches or inclusions create visible haze. These demands raise the processing cost but ensure that the final part achieves the clarity required in optical lenses, medical housings, packaging windows, and architectural glazing.

Transparent materials are thus highly valuable but technically demanding. Their performance is tied not only to optical purity but also to the manufacturer’s ability to maintain precision during machining and finishing.

What is Translucent Material?

Translucent materials occupy the middle ground between clarity and opacity. They allow partial light transmission, typically in the range of 50–80%, but scatter it in the process. This means objects behind them appear blurred yet illuminated. Frosted glass, for example, transmits 70–80% of light while providing privacy. Plastics such as translucent acrylic or polycarbonate diffusers are used extensively in lighting, softening LED brightness to create a comfortable environment.

Controlling translucency is both a material and a process decision. Additives can be introduced during injection molding to increase haze, while post-processing methods such as bead blasting, sandblasting, or acid etching create frosted finishes on plastics or glass. In office lighting projects, a frosted polycarbonate diffuser transmits enough light to maintain brightness but scatters it evenly, reducing glare and eye strain.

This combination of illumination and visual comfort explains why translucent materials are favored in architecture, consumer products, and electronics. They serve not only functional roles—like diffusing light—but also improve user experience by shaping how light interacts with a space or device.

What is Opaque Material?

Opaque materials block all visible light, with transmission effectively at zero. Their performance depends on reflection and absorption, rather than transmission. Metals such as steel, aluminum, and titanium dominate this category, combining opacity with strength, machinability, and durability. Dense plastics like ABS or filled nylon, along with ceramics, wood, and stone, are also common opaque materials in engineering.

Applications extend from structural frames and protective housings to shielding components that must resist light, heat, or radiation. An aluminum enclosure not only prevents light penetration but also dissipates heat, while a steel housing shields electronics from impact and environmental stress. These examples show that opacity often comes paired with mechanical performance.

From a machining perspective, opaque materials are the most straightforward to process. CNC milling and turning of metals or opaque polymers do not require concern for clarity, but strict tolerance control and surface finish quality remain essential. This balance of opacity, strength, and manufacturability explains why opaque materials dominate structural and protective applications across industries.

Transparent vs Translucent vs Opaque: Key Differences

The three categories differ in light transmission, clarity, and industrial use. Transparent materials provide clear imaging with transmission above 90%, translucent materials scatter light and typically transmit 50–80%, while opaque materials block light entirely. These distinctions influence where each is used: transparent for optics and packaging, translucent for lighting and privacy, and opaque for strength and protection.

In testing, standards such as ASTM D1003 (haze and transmission in plastics) and ISO 9050 (optical properties of glass) provide engineers with quantitative ways to measure these properties. Data-driven selection ensures that material choice aligns with both functional and manufacturing requirements.

Manufacturing Methods for Transparent and Translucent Parts

CNC Machining

CNC machining is a precise method for producing transparent and translucent parts, particularly for prototypes and low-volume runs. Acrylic and polycarbonate are common choices because they combine machinability with optical properties. However, cutting operations often introduce tool marks, stress whitening, or localized heating that reduce clarity. Engineers mitigate these issues by selecting sharp, diamond-coated tools, controlling spindle speeds, and using coolant to reduce thermal stress.

Even with optimized cutting parameters, post-processing is critical. Flame polishing can quickly restore edge clarity at lower cost, while vapor polishing provides uniform optical quality, even on complex internal geometries. These finishing steps transform a functional plastic block into an optical-grade component suitable for displays, housings, and protective covers.

Acrylic CNC Machining Case Example

In November 2024, JeekRapid completed a custom acrylic machining project that demonstrated both the opportunities and challenges of working with transparent plastics. The part was designed as a diagnostic housing requiring full visibility of internal fluid channels. CNC milling was chosen to achieve the required dimensional accuracy, but the process also introduced issues such as tool marks and stress whitening along cut edges. To address this, the team applied optimized spindle speeds, single-flute cutters, and continuous cooling to minimize heat buildup.

After machining, the components underwent finishing processes to restore optical performance. Flame polishing improved edge clarity, and vapor polishing delivered uniform, glass-like transparency across curved surfaces. The final parts met strict visual and dimensional requirements, enabling the client to integrate them directly into medical equipment. This project highlighted how acrylic machining, when combined with proper tooling and finishing, can deliver components that balance function, durability, and optical precision.

You can see more details about this project on our Facebook page.

Injection Molding

Injection molding enables large-scale production of both clear and translucent parts, but success depends heavily on mold design and finishing. Optical-grade components require mirror-polished molds, precise temperature control, and carefully selected resins. Additives can be introduced to adjust haze, creating frosted finishes directly during molding for diffusers or privacy panels.

Compared to machining, injection molding offers higher efficiency for volume production, but it also introduces challenges. Any imperfection in the mold surface or contamination in the resin can create permanent defects. Engineers working on medical devices or lenses must often combine high-grade materials with clean-room manufacturing to maintain consistency.

Surface Finishing

Surface finishing techniques provide additional control over how light interacts with a part. Sandblasting and bead blasting are common for plastics and glass, producing uniform translucency by scattering light at the surface. Chemical etching offers more precision, enabling patterned translucency in architectural panels or decorative products.

For engineers, these treatments expand design flexibility. A transparent acrylic sheet can be converted into a translucent diffuser with a controlled matte finish, while frosted glass panels improve privacy without sacrificing brightness. Surface finishing not only refines appearance but also tailors functionality, bridging the gap between material science and user experience.

Applications in Projects

Engineering and Construction

In construction, transparent, translucent, and opaque materials are often combined to achieve performance and aesthetics. Transparent glazing maximizes daylight and visibility, while translucent skylights diffuse sunlight to reduce glare. Opaque aluminum or steel frames provide structural integrity, supporting panels that cannot bear loads alone.

Modern office buildings highlight this synergy. Clear curtain walls create openness, frosted panels add privacy in meeting rooms, and opaque mullions carry mechanical loads. These design strategies enhance energy efficiency, occupant comfort, and visual appeal, showing how optical properties shape architectural performance.

Consumer Products

Consumer goods illustrate how different transparency levels directly affect user experience. Transparent smartphone cases showcase the device while protecting it. Translucent lamp covers soften LED light, making living spaces more comfortable. Opaque polymer housings shield electronics and ensure durability.

Designers often blend these categories in a single product. A kitchen appliance may use a transparent window to monitor contents, a translucent indicator light for gentle signaling, and an opaque body for mechanical strength. This layered use demonstrates how optical choices drive functionality and branding at the same time.

Medical and Optical Devices

Medical and optical products demand high standards where transparency and precision intersect. Transparent polycarbonate housings allow clear observation of diagnostic processes. Translucent covers in surgical lamps diffuse light evenly, improving accuracy and reducing glare for surgeons. Opaque metals and polymers protect sensitive electronics and ensure sterility.

Here, material selection aligns with safety and regulation. Standards such as ISO 10993 for biocompatibility and ASTM D1003 for light transmission guide engineers in balancing optical clarity with structural integrity. These requirements make the medical sector a prime example of how transparency levels influence both design and compliance.

Conclusion

Transparent, translucent, and opaque materials each serve distinct roles in modern manufacturing. Transparent polymers like acrylic maximize clarity, translucent diffusers create visual comfort, and opaque metals provide strength and shielding. Selecting the right material involves balancing performance with manufacturability, guided by data, standards, and practical experience.

JeekRapid supports this process with CNC machining, injection molding, and finishing services tailored to optical and structural requirements. From optical-grade acrylic parts to frosted polycarbonate diffusers and precision-machined metal housings, JeekRapid ensures ISO-certified quality for every project.

Upload your CAD drawing today to request a free quote and see how JeekRapid transforms design requirements into finished products.

FAQ

What is translucent?

Translucent materials transmit light but scatter it in the process, usually within a range of 50–80%. This scattering makes objects behind them appear blurred but still illuminated. Engineers use them in applications like diffusers, skylights, and privacy panels.

What is the difference between transparent and translucent?

Transparent materials transmit over 90% of light with minimal haze, providing clear vision. Translucent materials scatter light and reduce clarity but are valuable in designs where glare reduction or privacy is required.

What are examples of translucent materials?

Frosted glass, translucent polymers, wax paper, and thin fabrics such as organza are typical examples. In engineering, polycarbonate diffusers are widely used in LED lighting to soften brightness.

Is opaque see-through?

No. Opaque materials block visible light completely. Metals, ceramics, and dense plastics such as ABS or nylon are widely used because opacity aligns with strength and protection.

Why is glass transparent?

Glass is transparent because its atomic structure does not absorb visible light frequencies. Its transmission exceeds 90% when produced with minimal impurities. Treatments such as etching or frosting can change its behavior, turning it translucent for privacy or decorative use.