Delrin is an engineering plastic ideal for CNC machining of high-precision, low-friction components. JeekRapid machines Delrin parts with tight tolerances (±0.02 mm), excellent surface finish, and rapid turnaround—ideal for low volume production of gears, bushings, sliders, and enclosures. Compared to Nylon, Delrin offers better dimensional stability and lower moisture absorption.

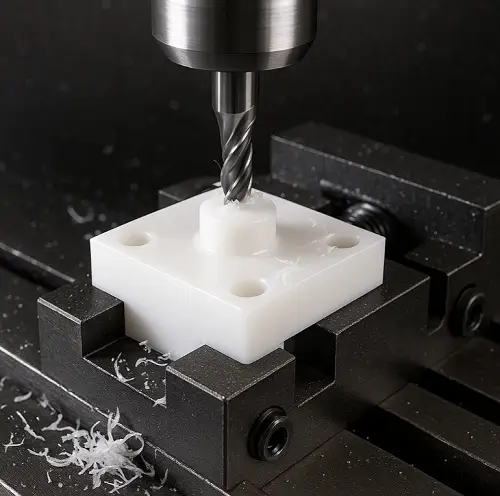

In the world of precision plastic machining, Delrin—also known as polyoxymethylene (POM) or acetal—is one of the most commonly requested engineering thermoplastics for CNC parts. Known for its excellent dimensional stability, low friction, and high mechanical strength, Delrin is ideal for manufacturing components that demand precision, smooth motion, and wear resistance. JeekRapid specializes in machining Delrin for low volume and prototype applications, supporting engineers across industries from robotics to medical devices.

This guide explores the complete engineering perspective of Delrin CNC machining, including material selection tips, machining parameters, structural considerations, cost factors, and common part types.

What Is Delrin and Why Is It Used in CNC Machining?

Delrin is a brand name for acetal homopolymer resin, produced by DuPont. It’s part of the broader POM (polyoxymethylene) family, which includes both homopolymer and copolymer grades. Delrin offers high strength, stiffness, and low moisture absorption, making it suitable for close-tolerance parts in humid or lubricated environments.

Key material characteristics:

- High dimensional stability

- Excellent wear resistance

- Low coefficient of friction

- Natural lubricity (ideal for sliding components)

- Good machinability and chip control

These properties make Delrin a top choice for gears, bushings, spacers, cams, bearings, and other mechanical parts requiring precision motion and low friction operation.

Delrin vs Other Engineering Plastics

Understanding how Delrin compares to other plastics helps guide material selection based on performance and machining behavior.

Material Comparison Table

| Property | Delrin (POM) | Nylon 6 | ABS | PTFE | UHMW-PE |

|---|---|---|---|---|---|

| Tensile Strength | High | Medium | Low | Low | Medium |

| Moisture Absorption | Very Low | High | Medium | Very Low | Low |

| Friction Coefficient | Low | Medium | Medium | Very Low | Very Low |

| Machinability | Excellent | Good | Fair | Poor | Fair |

| Dimensional Stability | Excellent | Poor | Fair | Fair | Poor |

Delrin is often preferred over Nylon for high-precision applications because it does not absorb water, which can lead to dimensional changes in Nylon parts. Compared to ABS, Delrin has better mechanical properties and lower friction. It’s not as slick as PTFE or UHMW but offers better machinability and stability.

Common Delrin CNC Machined Parts

Delrin is often used in:

- Precision gears and sprockets

- Bushings and low-friction spacers

- Valve seats and fluid control components

- Bearing housings and rollers

- Sliding cams and linkages

- Electrical insulators and enclosures

These parts are found in automation systems, diagnostic equipment, packaging machinery, consumer devices, and more.

Design Considerations for Machining Delrin

Delrin is forgiving to machine, but good design practices improve part quality, reduce waste, and lower machining time.

Key design tips

- Avoid thin walls under 1.0 mm to reduce risk of warping

- Use fillets >1.0 mm on internal corners to reduce tool stress

- For threaded holes, use heat-set or press-fit inserts instead of fine threading plastic

- Include radiused edges to reduce stress concentration

- Maintain uniform wall thickness for better dimensional control

Tolerances for Delrin CNC Parts

Standard tolerance for Delrin parts is ±0.05 mm. However, tighter tolerances (±0.01–0.02 mm) are achievable with proper fixturing and temperature control during machining. Delrin’s low thermal expansion helps maintain consistency across production batches.

Typical Delrin Part Sizes

JeekRapid machines Delrin components in sizes ranging from 10 mm brackets to 500 mm sliding housings. Most low volume parts fall within the 50–150 mm range.

Threading and Inserts in Delrin Parts

Due to its soft nature, fine threads directly cut into Delrin may not hold up under repeated stress. Engineering best practices include:

Metal Inserts

- Installed via heat or ultrasonic insertion

Coarse Threads

- Use larger thread pitch when threading directly into plastic

Self-Tapping Screws

- Acceptable for assembly but less repeatable

Boss Design Considerations

- Add material around threaded features to prevent cracking

Surface Finish and Post-Processing

Delrin typically machines to a smooth matte finish. For improved aesthetics or function:

Bead Blasting

- Can reduce gloss and provide uniform texture

Laser Marking

- Possible for part IDs or logos

Polishing Limitations

- Feasible but limited due to low melting point

Color Availability

- Coloring Delrin is not standard; natural color is white or black

Cost of Delrin CNC Machining

Delrin is cost-effective for low volume production due to easy chip removal and fast cycle times.

Cost Overview by Quantity

| Quantity | Avg. Cost per Part | Notes |

| 1–10 pcs | $50–$120 | Prototype or custom parts |

| 11–100 pcs | $15–$45 | Fixture amortized |

| 101–500 pcs | $8–$20 | Efficient batch processing |

Design features such as deep pockets, thin walls, or tight fits may increase costs.

Comparison: Delrin vs Nylon in CNC Applications

| Feature | Delrin (POM) | Nylon 6 |

| Moisture Resistance | Excellent | Poor (absorbs water) |

| Friction & Wear | Lower friction | Moderate friction |

| Strength & Stiffness | High stiffness | More flexible |

| Cost | Moderate | Sometimes cheaper |

| Machinability | Excellent finish | Good, more stringing |

JeekRapid’s Delrin CNC Machining Capabilities

JeekRapid provides precision Delrin CNC machining with no minimum order quantity. Services include:

- In-house milling, turning, and secondary operations

- Tapped holes, press-fit inserts, surface texturing

- Dimensional inspection with 2D drawings and 3D CAD

- Fast lead times for 1 to 1000 pcs

All parts are produced using high-quality bar stock and inspected before shipment.

Related Reading

Looking for more on plastic machining? You might also be interested in:

- CNC Machining for Engineering Plastics

- Threaded Inserts in Plastic CNC Parts

- Delrin offers excellent stability and machinability, but it is often evaluated alongside Nylon in real projects. Read our full Delrin vs Nylon CNC machining comparison.

FAQ

Here are some of the most common questions engineers ask about Delrin machining.

Is Delrin suitable for high precision CNC parts?

Yes, Delrin maintains tight tolerances and dimensional stability.

Can I use threads in Delrin plastic?

Yes, but threaded metal inserts are recommended for durability.

What is the best application for Delrin parts?

Gears, bushings, and wear components in automation and mechanical systems.

How does Delrin compare to Nylon for machining?

Delrin offers better dimensional control and surface finish.

What’s the typical lead time for Delrin parts?

3–7 business days depending on quantity and complexity.

Can Delrin be laser marked?

Yes, laser marking is supported.

Do you offer black Delrin parts?

Yes, natural Delrin comes in white or black.

Can I order just 5 pieces?

Yes, JeekRapid accepts low quantity orders without MOQ.

Are Delrin parts food-safe?

Yes, medical and food-safe grades are available on request.

How do I get a quote for Delrin machining?

Upload your drawing to jeekrapid.com to get a fast response.