Aluminum, as a lightweight metal, is widely used thanks to its low density, corrosion resistance, and excellent thermal conductivity. In automotive lightweighting, aerospace, machinery manufacturing, and consumer products, cast aluminum and aluminum casting processes play a crucial role. From large engine housings to everyday furniture and cookware, cast aluminum parts have become an essential component of modern manufacturing.

This article provides a comprehensive overview of cast aluminum and aluminum casting—covering definitions, processes, material properties, tooling, applications, surface finishing, and future trends.

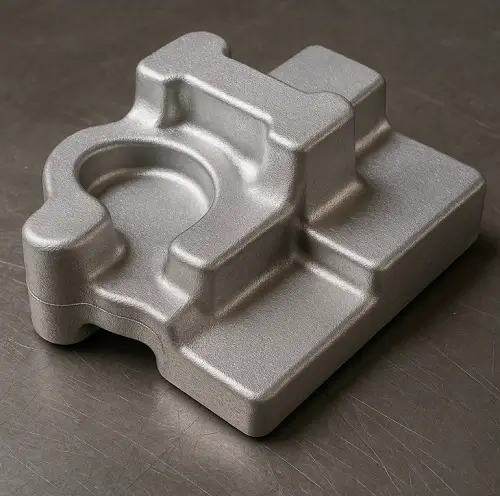

What Is Cast Aluminum?

Cast aluminum refers to aluminum or aluminum alloys that are shaped through casting processes. Unlike wrought aluminum, which is produced through forging or rolling, cast aluminum allows for complex geometries to be formed in a single step, reducing the need for extensive machining.

Aluminum casting is the process itself, which includes sand casting, die casting, investment casting, permanent mold casting, and other methods. Simply put: casting aluminum is the process, and cast aluminum is the product.

Comparison of Cast Aluminum with Other Metals

Cast Aluminum vs Cast Iron

When comparing density, cast aluminum is much lighter (~2.7 g/cm³), while cast iron is significantly heavier (~7.2 g/cm³). Aluminum also provides good corrosion resistance, whereas cast iron rusts easily without protective coatings. Although cast iron offers higher strength, its poor ductility makes it brittle. Cast aluminum strikes a better balance between strength and weight, which explains its dominance in automotive lightweighting.

Cast Aluminum vs Wrought Aluminum

One of the main advantages of cast aluminum is its ability to form complex shapes quickly and cost-effectively, such as housings, structural components, and heat-dissipating parts. Wrought aluminum, by contrast, features a continuous, dense grain structure and superior mechanical properties, often achieving tensile strengths above 400 MPa. For this reason, cast aluminum is preferred for moderate-load applications, while wrought aluminum is chosen for high-strength and impact-resistant components like aircraft structures and sporting goods.

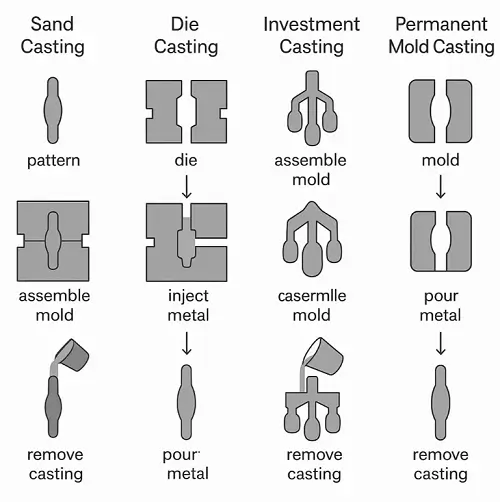

Major Aluminum Casting Processes

Sand Casting

Sand casting uses sand molds to shape molten aluminum. It is cost-effective and flexible, ideal for large and complex parts such as engine blocks and pump housings. The drawback is rough surface finish and limited dimensional accuracy, often requiring machining.

In industrial practice, molding sand typically contains 85–95% quartz sand and 5–10% binders and water. Pouring temperatures range from 680–740 °C, producing a surface roughness of Ra 12.5–25 μm and dimensional accuracy of CT10–CT13. Suitable for large aluminum castings exceeding 500 kg.

Die Casting

Die casting forces molten aluminum into steel molds under high pressure, achieving smooth surfaces and high dimensional accuracy. It is widely used in automotive engine housings, transmission cases, and electronic enclosures. Internal porosity is a common limitation, reducing weldability and impact resistance.

Die casting pressures range from 30–120 MPa. H13 tool steel molds typically last 50,000–150,000 cycles. Common alloys include A380 and ADC12, with tensile strengths of 200–250 MPa. Dimensional accuracy is CT6–CT8, with surface roughness around Ra 1.6–3.2 μm.

Investment Casting

Also known as lost-wax casting, this process uses wax models coated with ceramic layers to form a shell mold. Once the wax is melted out, molten aluminum fills the cavity. Investment casting produces highly complex, detailed components, often for aerospace and medical industries, though it is costly and time-consuming.

Shell molds typically use 6–10 ceramic layers with a thickness of 7–10 mm. Pouring temperatures are controlled at 700 ± 10 °C, achieving CT5–CT7 accuracy and Ra 1.6–6.3 μm surface finishes.

Permanent Mold Casting

Permanent mold casting uses reusable steel or iron molds, yielding denser and stronger parts than sand casting. It is suitable for automotive pistons, cylinder heads, and heavy machinery components. However, tooling costs are high, making it less economical for small batches.

Molds are preheated to 200–300 °C, while molten aluminum is poured at 690–730 °C. Resulting parts achieve tensile strengths of 220–280 MPa and elongation of 3–8%, outperforming sand-cast equivalents.

Plaster Molding and DIY Casting

Plaster molds are often used for prototypes and small batches, capable of reproducing fine surface details. Hobbyists sometimes attempt DIY aluminum casting—such as “ant hill casting”—but these methods lack process control, leading to defects like porosity and shrinkage.

Industrial plaster mold castings achieve CT6–CT9 accuracy, but molds have poor heat resistance and are limited to low-pressure casting. DIY parts generally suffer from inconsistent quality and reduced strength.

Summary of Casting Process Selection

Each casting method has its own advantages and limitations. Sand casting is low-cost and flexible, but parts often require secondary machining. Die casting delivers excellent accuracy and surface finish, making it ideal for mass production of housings and enclosures, though porosity limits its use in high-stress components. Investment casting excels in complexity and fine detail, but is more expensive and time-consuming, suitable for aerospace or medical applications. Permanent mold casting produces stronger, more consistent parts than sand casting, but requires higher tooling investment. Plaster mold and DIY methods are useful for prototypes and experimentation, yet lack the quality control required for industrial production.

For critical applications where safety, durability, and repeatability matter, consulting a professional foundry is always the best approach.

Materials and Properties of Cast Aluminum

Cast aluminum alloys are broadly categorized into silicon-based and copper-based groups. Silicon alloys like A356 exhibit excellent fluidity and corrosion resistance, commonly used in automotive and structural components. Copper-based alloys like 319 offer higher high-temperature strength and hardness, suitable for engine components.

Mechanical performance varies by process. Sand castings achieve tensile strengths of 150–200 MPa with elongation <3%. Permanent mold and die castings reach 220–280 MPa with elongation of 3–8%. Heat-treated alloys such as A356-T6 can exceed 300 MPa.

Tooling and Manufacturing Workflow

Molds directly determine cost and performance. Sand molds are inexpensive and flexible but disposable; metal molds are costly but reusable and efficient, ideal for high-volume production.

Die casting molds can endure hundreds of thousands of cycles, while plaster molds last only dozens. Choosing the right tooling balances cost, efficiency, and part accuracy.

Typical Applications of Cast Aluminum

Automotive

In automotive engineering, cast aluminum is widely used in engine blocks, cylinder heads, transmission housings, suspension components, and wheels. Substituting cast iron with aluminum reduces weight by 20–30%, improving fuel efficiency and EV driving range, while its high thermal conductivity improves engine cooling.

Aerospace

Aerospace applications also rely heavily on aluminum castings, from cabin frames and landing gear housings to ducts and seat structures. The material’s high strength-to-weight ratio and corrosion resistance make it indispensable in reducing overall mass. Satellites further benefit from cast aluminum in structural components.

Machinery and Equipment

Pumps, compressors, and motor housings often use cast aluminum for strength and thermal conductivity. Lighter housings reduce energy consumption and extend service life.

Electronics and Lighting

Heat dissipation makes cast aluminum ideal for enclosures and heat sinks. LED streetlights, communication housings, and power electronics commonly use die-cast aluminum.

Architecture and Home

In architecture and home furnishing, aluminum castings appear in furniture, railings, and window frames. Compared with cast iron, they are lighter, more corrosion-resistant, and easier to maintain, making them well-suited for outdoor use.

Cookware and Consumer Goods

Cookware such as pans, coffee machine parts, and baking trays leverage aluminum’s thermal conductivity for even heating. Non-stick coatings further enhance usability.

Art and Creative Design

Artists often employ cast aluminum for sculptures and decorative objects. “Ant hill casting” is a notable example, where molten aluminum poured into abandoned ant colonies produces intricate natural patterns.

Surface Finishing Methods for Cast Aluminum

Anodizing

Forms an oxide film 5–25 μm thick, up to 70 μm in hard anodizing, with hardness over HV 400. Improves wear and corrosion resistance, and can be dyed in multiple colors. Widely used in aerospace parts, automotive trim, and electronics housings.

Powder Coating

Applies 60–120 μm of cured powder paint with strong adhesion and weather resistance. Common in outdoor furniture, building components, and lighting housings.

Electrophoretic Coating (E-coating)

Creates 15–35 μm coatings that uniformly cover complex geometries. Offers excellent corrosion protection, with salt spray resistance over 500 hours. Common in automotive and home appliances.

Polishing and Mechanical Grinding

Produces smooth, reflective finishes, reducing surface roughness to Ra 0.2–0.4 μm. Used in cookware, medical instruments, and decorative parts, often as pretreatment for plating or anodizing.

Conversion Coatings

Chromate and phosphate treatments form thin films 0.2–2 μm thick, enhancing corrosion resistance and paint adhesion without altering dimensions. Common in aerospace and defense components, with non-chromate alternatives increasingly used for environmental compliance.

Future Trends in Cast Aluminum

Cast aluminum is evolving alongside additive manufacturing. 3D-printed sand molds and hybrid mold-making technologies shorten development cycles and allow more complex geometries.

Sustainability is another focus. Aluminum is highly recyclable, with recycling rates exceeding 90%. Using secondary aluminum saves up to 95% of the energy required for primary smelting, making recycled castings key to reducing carbon footprints in manufacturing.

FAQ

What is cast aluminum?

Aluminum alloy shaped by casting processes.

Is cast aluminum strong?

Typically 200–300 MPa tensile strength, sufficient for most mechanical uses.

Can cast aluminum be painted?

Yes, via painting, powder coating, or anodizing.

Cast aluminum vs wrought aluminum?

Cast is suited for complex shapes, wrought for high-strength applications.

How to cast aluminum at home?

Simple furnaces and plaster molds can be used, but quality and strength are limited.

What is die-cast aluminum?

Aluminum cast under high pressure into steel molds, delivering precise, high-volume parts.

Conclusion

Cast aluminum and aluminum casting processes combine cost efficiency, design flexibility, and strong performance across industries. From sand casting to die casting, from prototypes to large-scale production, each method offers distinct benefits.

For projects requiring tight tolerances and reliable performance, working with a professional manufacturer is essential. JeekRapid provides extensive expertise in aluminum casting and CNC machining, delivering one-stop solutions from prototypes to small-batch production. Upload your CAD files today to receive a fast and accurate quotation.