ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic engineering plastic in our daily life. With good mechanical strength, impact resistance and dimensional stability, ABS is widely used in the automotive, electrical and electronic, consumer goods and medical industries. When developing prototypes or mass production parts, engineers usually choose ABS as the preferred material for manufacturing, because ABS can be quickly prototyped through CNC machining, and can also achieve large-scale production through injection molding and extrusion.

What is ABS Plastic?

ABS is a polymer composed of three monomers: acrylonitrile, butadiene and styrene. Acrylonitrile provides strength and chemical resistance, butadiene gives toughness and impact resistance, and styrene can improve flowability and surface appearance. There are multiple ratios, and ABS materials with different ratios can balance rigidity, toughness and processability. Compared with polypropylene (PP) or polyethylene (PE), ABS has lower shrinkage and higher strength, and is often classified by engineers as a mid-level engineering plastic.

Main Properties of ABS

Impact resistance

ABS has relatively strong impact resistance, and can maintain good toughness even in low temperature environments, not easy to break due to external force, which makes it widely used in automotive trims, sports equipment and consumer goods.

Tensile strength

The tensile strength of ABS is usually 40–50 MPa, and the flexural strength is 60–80 MPa. The performance is at a medium to high level, which can meet the requirements of most structural parts for rigidity and stability.

Stability

Dimensional stability is also excellent. Its shrinkage rate is 0.4–0.7%, significantly lower than that of polyolefin plastics. The high geometric accuracy of processed parts makes it suitable for CNC machining and injection molding precision parts.

Heat resistance

The heat deflection temperature (HDT) of ABS is 80–100 ℃, which belongs to the medium heat resistance range. It performs stable under normal temperature or moderate temperature applications. High temperature use is possible but not recommended. For higher heat resistance requirements, our given solution is to mix ABS+PC materials.

Insulation

ABS plastic is not significantly affected by humidity and temperature changes, and is more used in electronic and electrical equipment.

Good surface treatment

In addition, ABS naturally has gloss, and can be further processed by painting, electroplating, screen printing and other secondary processing. In consumer electronics and automotive interiors, the application of ABS plastic is particularly common.

Common Applications of ABS

-

Automotive industry: dashboards, air outlets, interior panels.

-

Electronics: electronic housings, sockets, switch panels.

-

Consumer goods: appliance housings, sports equipment, toys (the typical example is LEGO bricks).

-

Medical equipment: laboratory devices, non-implantable housings.

-

Rapid prototyping: CNC ABS is commonly used for functional prototypes and small-batch trials.

ABS Plastic Manufacturing Process

CNC Machining

ABS sheets or rods obtained by cutting, with an accuracy of ±0.02 mm. No mold is required, and both small-batch production and prototype verification can use CNC machining. The parts have high strength and stability, and the surface after machining is relatively rough, requiring polishing or painting.

JeekRapid ABS case: An automotive manufacturer customer independently developed, in the process of developing a new model, used CNC ABS prototypes to quickly verify the geometric design and assembly effect of dashboard buttons, and after confirming that the design was reasonable, then invested in injection mold production, saving the time and cost of repeated mold modifications.

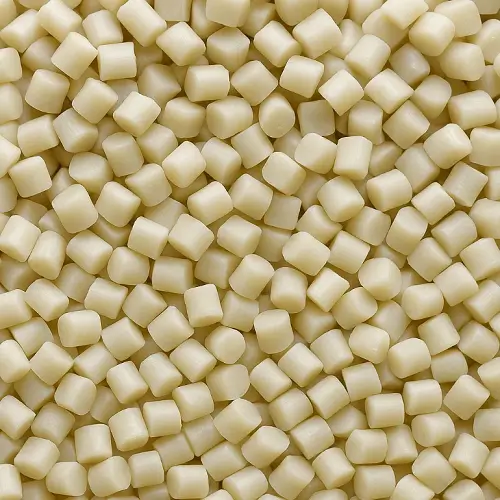

Injection Molding

Injection molding is through mold pressing, molten ABS pellets are injected into the mold cavity and then cooled to form, with an accuracy of ±0.05–0.1 mm. Once the mold is made, large-scale production can be carried out, and the unit cost is low. Mold investment is high, and the ABS plastic produced has smooth surfaces, which can be directly electroplated or painted.

Extrusion Molding

Molten ABS is extruded through a die to obtain pipes, profiles or sheets. The accuracy is ±0.1–0.3 mm, and mass production is also possible. Common applications include drainage pipes, sheets and automotive trims.

Thermoforming (Vacuum Forming)

Heated and softened ABS plastic is formed by vacuum or pressure adsorption to the mold surface. The accuracy is ±0.2–0.5 mm, the surface effect is average, and the mold cost is low. It is commonly used in packaging trays, appliance panels and automotive interior parts.

3D Printing (FDM)

This is a common method for ABS, ABS plastic is deposited layer by layer, with an accuracy of ±0.1–0.3 mm. No mold is required, start-up is fast, suitable for small batches and complex geometry verification. However, the mechanical properties are lower than CNC or injection molded parts, and the surface has layered texture.

Disadvantages of ABS

ABS plastic has certain limitations. Its heat resistance is limited, and in environments above 100 ℃ it is easy to deform or decline in performance, requiring blending with other plastics, and cannot meet long-term high-temperature applications. ABS has poor weather resistance, exposed to ultraviolet rays will yellow and embrittle, outdoor applications require protective coatings or modification. Chemical resistance is also average, easily attacked by strong acids, alkalis and some organic solvents. ABS has good dimensional stability, but is still not as good as high-performance engineering plastics such as POM or PA, and may require additional design compensation in high-precision assemblies. This is also why engineers define ABS plastic as a mid-level engineering plastic (mentioned at the beginning).

FAQ

1. How much temperature can ABS plastic withstand?

The heat deflection temperature is 80–100 ℃, beyond this range it will soften or deform. For higher heat resistance, ABS/PC blends can be used.

2. What is the difference between ABS plastic and PC plastic?

ABS is low-cost and easy to process, suitable for medium strength requirements; PC has higher strength and toughness, better heat resistance, but higher cost. PC/ABS blends can combine the advantages of both.

3. Can ABS parts be polished or electroplated?

Yes. ABS has high surface energy, suitable for polishing, painting and electroplating. The automotive industry and consumer electronics industry have great development potential.

4. Is ABS plastic toxic?

ABS itself is non-toxic and meets food contact safety standards. But when burned or decomposed, it will release irritating gases, so ventilation should be paid attention to during processing.

5. Why can’t ABS plastic be used for medical implants?

Although ABS is non-toxic, it does not have long-term biocompatibility. In the environment of body fluids it will degrade and may cause inflammation. Therefore, ABS is only suitable for medical device housings or disposable parts, and not suitable for implantation in the human body.

ABS plastic achieves a good balance between strength, toughness, dimensional stability and manufacturing flexibility. CNC and 3D printing are suitable for small-batch prototypes, injection molding and extrusion are more suitable for mass production, and thermoforming is suitable for medium-batch thin-walled parts. Although ABS has limitations in heat resistance, weather resistance and chemical resistance, through reasonable process selection and modification treatment, it is still an indispensable engineering plastic in manufacturing.

JeekRapid can provide ABS CNC machining and injection molding services, covering from rapid prototyping to mass production, providing customers with high precision and high efficiency solutions. Upload your CAD, and we will reply within 24 hours.