In precision machining, understanding the strength of metals is essential for both design and production. Tensile strength, yield strength, compressive strength, and hardness not only determine how a material performs in service but also influence how the material can be cut, milled, drilled, or finished. High-strength steels demand different tool geometries and cutting speeds compared with softer metals such as aluminum or copper. Tungsten, titanium, and specialty alloys may rank among the strongest, but machinists and engineers must balance material properties with manufacturability.

The search for the strongest metal is more than a theoretical exercise. For manufacturers, knowledge of strength guides tool selection, machining strategies, and post-processing treatments. For engineers, strength data determines whether a part can safely withstand stresses in aerospace, defense, or medical applications. This article examines the strongest metals, explains key parameters, presents comparative charts, and explores processes that enhance strength—all within the context of machining.

Understanding Strength of Metals

What is tensile strength of steel?

Tensile strength is the maximum stress a material can withstand before fracturing under tension. For steel, values vary widely by grade. Mild steel reaches around 400 MPa (58,000 psi), while advanced tool steels and maraging steels can exceed 2000 MPa (290,000 psi). This wide range demonstrates why steel remains one of the most important engineering materials: grades can be tailored to applications ranging from structural beams to aerospace landing gear.

What is yield strength in steel?

Yield strength marks the stress point where a material transitions from elastic to plastic deformation. Below this point, steel returns to its original shape after load removal; above it, permanent deformation occurs. Typical yield strength for mild steel is about 250 MPa (36,000 psi), while high-strength low-alloy steels can reach 700 MPa or more. Engineers rely on yield strength when designing load-bearing structures to ensure safety under repeated stress.

What is compressive strength of steel?

Compressive strength refers to resistance against crushing or shortening under compression. Steel performs very well in compression, with values often exceeding tensile strength. This property explains why reinforced concrete uses steel bars: steel compensates for concrete’s weakness in tension, while concrete provides bulk compressive resistance.

What is ultimate tensile strength?

Ultimate tensile strength (UTS) is the maximum stress a material can endure in tension before breaking. For steels, UTS ranges from 400 MPa in mild grades to more than 2000 MPa in specialized alloys. Engineers measure UTS through standardized tensile testing, such as ASTM E8, which provides data for selecting metals in demanding applications like bridges, aircraft frames, and armor plating.

Toughness vs Hardness in Metals

Toughness measures the ability to absorb energy before fracturing, while hardness measures resistance to indentation or scratching. Chromium shows very high hardness but limited toughness, whereas stainless steels offer toughness without extreme hardness. Cutting tools require hardness for wear resistance, while armor materials prioritize toughness to prevent shattering.

Strongest Metals Ranked

Tungsten – Highest Tensile Strength

Tungsten is often regarded as the strongest natural metal because of its tensile strength of about 1510 MPa (219,000 psi) and the highest melting point of any metal at 3422 °C. These properties make tungsten valuable in aerospace components, electrical contacts, and military applications such as penetrators. The drawback is brittleness and machining difficulty, which restrict large-scale structural use.

Titanium – Best Strength-to-Weight Ratio

Titanium alloys provide tensile strengths of 900–1200 MPa with a density only about 60% that of steel, giving them the best strength-to-weight ratio among structural metals. Titanium is biocompatible, corrosion resistant, and widely used in aerospace structures, jet engines, and medical implants. While not as hard as tungsten or as strong as maraging steels, titanium remains indispensable where weight savings are critical.

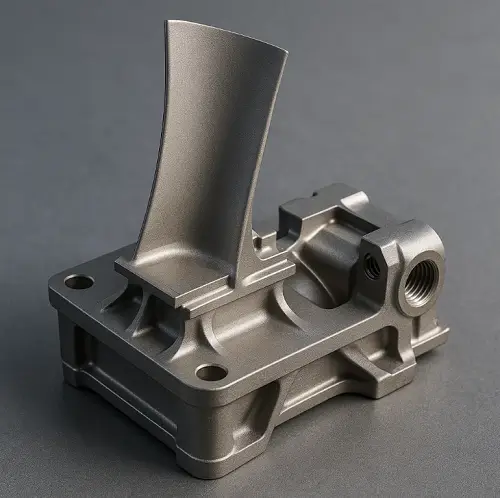

Steel Alloys – Balance of Strength and Toughness

Modern steels, including tool steels and maraging steels, reach tensile strengths above 2000 MPa (290,000 psi) while maintaining ductility and toughness. This balance makes steel unique: unlike tungsten or chromium, steels absorb impact without fracturing. Versatility in alloying and heat treatment enables grades suited to construction, automotive, and aerospace applications.

Chromium – Hardest Natural Metal

Chromium demonstrates outstanding hardness, measuring about 8.5 on the Mohs scale, which provides excellent resistance to wear and scratching. Brittleness and low toughness limit bulk applications, but chromium’s contribution as an alloying element in stainless steel enhances corrosion resistance. Chromium coatings also extend the life of tools and machinery by improving surface durability.

Osmium and Iridium – Densest and Highly Durable

Osmium and iridium are the densest natural metals, with densities above 22 g/cm³, and show impressive compressive strength and wear resistance. Rarity and brittleness restrict widespread use, yet these metals remain essential in precision instruments, electrical contacts, and scientific devices where extreme durability is required.

Table – Tensile Strength of Common Metals

| Metal / Alloy | Tensile Strength (MPa) | Tensile Strength (psi) | Notes |

|---|---|---|---|

| Mild Steel | ~400 | ~58,000 | Common structural steel |

| Stainless Steel | 500–1000 | 72,000–145,000 | Corrosion resistant |

| Tool Steel | 1000–2000 | 145,000–290,000 | High wear resistance |

| Maraging Steel | 2000+ | 290,000+ | One of the strongest steels |

| Titanium Alloy | 900–1200 | 130,000–174,000 | High strength-to-weight ratio |

| Tungsten | ~1510 | ~219,000 | Highest tensile strength |

| Chromium | ~560 | ~81,000 | Very hard, but brittle |

| Osmium / Iridium | ~400–600 | ~58,000–87,000 | Densest metals |

| Aluminum Alloy | 200–600 | 29,000–87,000 | Lightweight |

| Copper | ~210 | ~30,000 | Ductile, low strength |

Hardness and Durability of Metals

Hardness Chart of Metals

| Metal / Alloy | Mohs Hardness | Rockwell Hardness | Notes |

|---|---|---|---|

| Aluminum | 2.75 | ~15 HRB | Very soft, easy to machine |

| Copper | 3.0 | ~35 HRB | Ductile, conductive |

| Iron (Pure) | 4.0 | ~80 HRB | Basis of steels |

| Tin | 1.5 | ~5 HRB | One of the weakest metals |

| Lead | 1.5 | ~4 HRB | Very soft, low strength |

| Chromium | 8.5 | ~65 HRC | One of the hardest metals |

| Tungsten | 7.5 | ~60 HRC | Very high strength and hardness |

| Titanium | 6.0 | ~36 HRC | Balanced properties |

| Hardened Steel | ~7.0–8.0 | 55–62 HRC | Used in cutting tools |

What is the toughest metal?

Steel, especially maraging and alloy steels, ranks as the toughest material because it combines high strength with ductility. Toughness enables components to absorb energy without shattering, a requirement for armor, gears, and impact-resistant structures.

What is the most durable metal?

Durability arises from hardness, toughness, and corrosion resistance. Stainless steel and titanium alloys are widely considered the most durable because they maintain performance in harsh conditions such as saltwater, aerospace environments, and medical use.

Weakest and Softest Metals

What is the weakest metal?

Lead and tin are frequently identified as the weakest metals, both scoring around 1.5 on the Mohs scale. Alkali metals such as sodium and potassium are even weaker but too reactive for engineering use. Despite low mechanical strength, lead remains valuable in radiation shielding and tin in soldering.

Weakest material ever made

Alkali metals like cesium and potassium represent the lowest strength among metallic elements. Outside metals, aerogels are known for extremely low compressive strength, making them the weakest structural materials developed.

Steel Strength Charts and Data

| Type of Steel | Yield Strength (MPa) | Tensile Strength (MPa) | Rockwell Hardness (HRC) |

|---|---|---|---|

| Mild Steel | 250 | ~400 | ~15–20 HRC |

| Stainless Steel 304 | 215 | ~505 | ~20 HRC |

| HSLA Steel | 350–700 | 600–800 | ~25–30 HRC |

| Tool Steel (D2) | 700–1500 | 1000–2000 | ~55–62 HRC |

| Maraging Steel | 1400–2000 | 2000+ | ~50–60 HRC |

Yield strength of steel psi

In imperial units, yield strength for mild steel is about 36,000 psi, while maraging grades exceed 200,000 psi. Engineers often specify yield strength in psi when designing structures under American standards.

Ultimate strength of steel

Ultimate tensile strength for steels ranges from ~58,000 psi (400 MPa) in mild grades to over 290,000 psi (2000 MPa) in specialized alloys. This makes steel not the absolute strongest metal, but the most practical balance of strength, toughness, and cost.

How to Enhance Metal Strength?

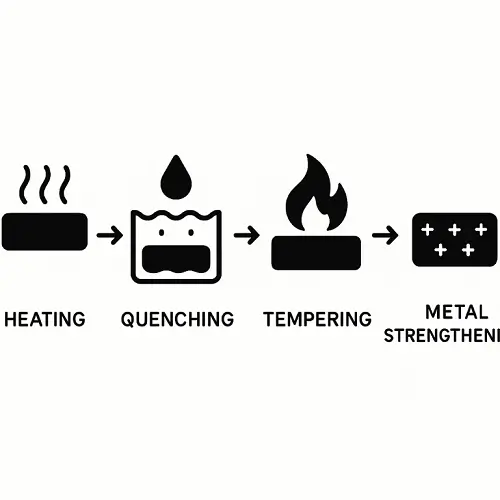

Heat Treatment Processes

Quenching followed by tempering creates martensitic structures in steels, raising tensile and yield strength while maintaining toughness. Case hardening processes, such as carburizing and nitriding, form hardened outer layers resistant to wear while preserving core ductility.

Alloying and Composition Control

Adjusting chemical composition dramatically alters performance. Chromium and nickel enhance corrosion resistance in stainless steels, molybdenum and vanadium increase strength in tool steels, and aluminum-vanadium blends give titanium alloys their high strength-to-weight ratio.

Surface Hardening and Coatings

Coatings such as TiN (titanium nitride) and DLC (diamond-like carbon) improve wear resistance in cutting tools and molds. Plasma nitriding and PVD (physical vapor deposition) extend service life by enhancing surface hardness beyond natural limits.

Cold Working and Strain Hardening

Plastic deformation processes such as rolling or forging increase dislocation density within metals, raising yield strength through strain hardening. This method boosts strength significantly but can reduce ductility, requiring careful design balance.

Applications of Strong Metals

Aerospace and Defense Applications

Titanium alloys dominate aerospace because of high strength-to-weight ratio. Tungsten serves in missile penetrators and aerospace parts exposed to extreme heat. High-strength steels remain vital in landing gear, armor, and military hardware.

Construction and Infrastructure

High-strength structural steels support skyscrapers, bridges, and heavy machinery. Their combination of tensile and yield strength ensures safety and durability under cyclic loads.

Medical and Consumer Products

Titanium provides biocompatibility for implants, prosthetics, and surgical tools. Stainless steels are indispensable for surgical instruments and food processing equipment where durability and hygiene are critical.

Conclusion

The strongest metal cannot be defined by a single property. Tungsten excels in tensile strength, chromium in hardness, titanium in strength-to-weight ratio, and advanced steels in toughness. For engineers and designers, the critical consideration is not only which metal is strongest, but which material can be effectively machined and optimized for performance.

JeekRapid specializes in machining metals across the strength spectrum—from aluminum to hardened tool steels, titanium, and tungsten alloys. With advanced CNC milling, turning, and surface finishing capabilities, JeekRapid delivers precision components while addressing the challenges of each material. Whether a project involves high-strength steel gears, titanium aerospace parts, or custom tungsten fixtures, JeekRapid provides machining expertise, inspection reports, and certification support to ensure reliable outcomes.

Upload your CAD drawing today to request a free quote and see how JeekRapid transforms the strongest metals into functional components.

FAQ

What is the strongest metal on earth?

Tungsten holds the record for tensile strength, but in practice advanced steels are chosen more often because they combine toughness, machinability, and availability.

What is the tensile strength of steel?

Depending on grade, steel ranges from 400 MPa in mild forms to more than 2000 MPa in maraging alloys, making it one of the most versatile materials in machining.

What is yield strength in steel?

Yield strength marks the limit before permanent deformation. Engineers use this property to decide safe load levels when designing gears, beams, and structural parts.

What is the hardest natural metal?

Chromium is the hardest natural metal with a Mohs rating of 8.5, but its brittleness means chromium is mainly used in stainless steel alloys and protective coatings.

What is the weakest commonly used metal?

Lead and tin are relatively weak but remain important in applications like soldering, shielding, and low-friction bearings where softness is an advantage.