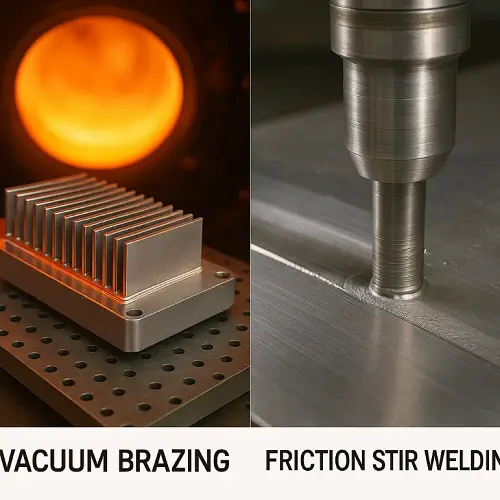

Aluminum alloys are widely used in aerospace, automotive, and electronics because they combine low weight with good thermal and mechanical properties. A recurring challenge is how to join aluminum components while keeping structural strength, corrosion resistance, and heat performance intact. Two methods often considered are vacuum brazing and friction stir welding (FSW).

These two processes both apply to aluminum but serve very different needs. Vacuum brazing is typically chosen for thermal systems and complex geometries, while friction stir welding is the solution for structural joints where high strength is required. Knowing their differences helps engineers make the right choice during design.

What Is Vacuum Brazing?

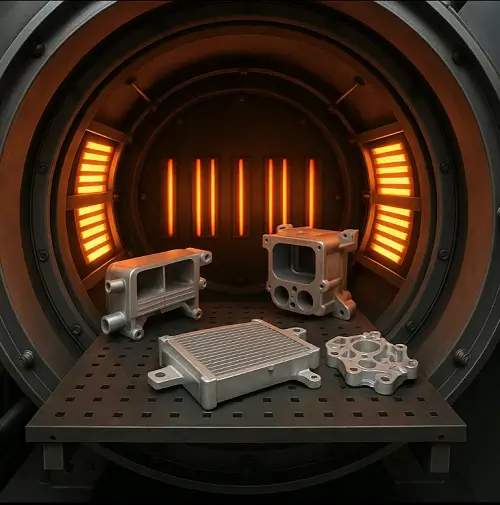

Vacuum brazing joins parts by melting a filler metal that flows between base materials through capillary action inside a vacuum furnace. The controlled environment avoids oxidation and eliminates the need for flux, which prevents residue contamination.

Key characteristics:

-

Fluxless operation – The vacuum atmosphere prevents oxidation, leaving joints clean.

-

Uniform heating – The entire part is heated evenly in the furnace, creating consistent bonds.

-

Ability to join complex geometries – Works well with thin-wall and multi-layer heat exchanger cores.

-

Resistance to thermal cycling – Joints withstand repeated heating and cooling without cracking.

Applications:

-

Aluminum heat exchangers in aerospace and automotive cooling

-

Electronic cooling plates and cold plates

-

Precision instruments requiring leak-tight joints

Vacuum brazing is widely used where accuracy and thermal conductivity are just as important as joint strength.

What Is Friction Stir Welding (FSW)?

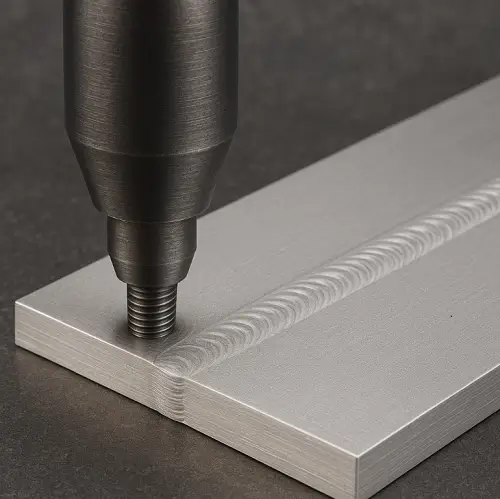

Friction stir welding is a solid-state joining method. A rotating tool pin penetrates and stirs the workpieces, generating frictional heat. The base material softens but does not melt; instead, it is forged together to form the joint.

Key characteristics:

-

High mechanical strength – Welds can reach strength levels close to or above the base alloy.

-

Low distortion – Limited heat-affected zone reduces stress and warping.

-

No filler required – The joint is formed only by the base material.

-

Scalable – Long, continuous welds are possible in sheet, panel, or extrusion assemblies.

Applications:

-

Aerospace skins and wing panels

-

Automotive panels, frames, and crash structures

-

Electric vehicle battery housings

-

Marine and rail structures requiring fatigue resistance

FSW is preferred for large aluminum structures that must carry load and resist fatigue.

Vacuum Brazing vs Friction Stir Welding: A Technical Comparison

| Criteria | Vacuum Brazing | Friction Stir Welding |

|---|---|---|

| Process type | Furnace-based, molten filler in vacuum | Solid-state, stirred joint without melting |

| Strength & integrity | Good for thermal cycling and corrosion protection | Very high strength, fatigue resistant |

| Best for | Thin-wall, multi-layer, complex assemblies | Large panels, structural weld seams |

| Applications | Heat exchangers, cooling plates, electronics | Aerospace panels, EV battery housings |

| Limitations | Requires furnace, slower batch process | Limited to linear paths, strong fixturing required |

Engineering Considerations

When deciding between vacuum brazing and FSW, the main factors include:

-

Geometry – Vacuum brazing suits complex passages; FSW suits straight or circular seams.

-

Load-bearing – FSW is better where mechanical loads dominate.

-

Thermal needs – Heat exchangers and cold plates typically rely on vacuum brazing.

-

Production scale – FSW is efficient for continuous panel joining; brazing fits precision batches.

-

Materials – Both work with aluminum alloys, but brazing filler selection can impose limits.

Reminder: These two processes are not substitutes. In practice, components brazed in vacuum may later be welded into larger assemblies using FSW.

Case Examples

-

Aerospace: Heat exchanger cores are vacuum brazed, then installed into structures with FSW panels.

-

Electric vehicles: Battery cooling plates are vacuum brazed for tight sealing, while housings use FSW for crash strength.

-

Defense: Missile skins use FSW, while internal cooling modules are vacuum brazed.

These cases show how both processes can exist in the same product, each addressing a different requirement.

JeekRapid’s Capabilities

JeekRapid offers both vacuum brazing and friction stir welding services. With advanced vacuum furnaces and FSW equipment, the company supports projects from prototypes to production runs.

-

Thermal management parts are joined with flux-free vacuum brazing for clean, leak-tight performance.

-

Structural parts are joined with FSW for high fatigue strength and dimensional accuracy.

-

Engineers review drawings and recommend the most suitable process or a combination of both.

Upload your drawing to request a quote, and JeekRapid will advise the best path to meet strength, cost, and delivery goals.Whether you choose vacuum brazing or friction stir welding, understanding traditional methods remains valuable. See our detailed aluminum welding guide for an overview of techniques used across industries.

FAQ

1. Is vacuum brazing stronger than welding?

Not in all cases. It provides excellent leak-tightness and corrosion resistance, but FSW usually produces stronger structural joints.

2. Can all aluminum alloys be friction stir welded?

Most grades can, though some high-strength aerospace alloys need special tools and parameters.

3. Why is vacuum brazing used for heat exchangers?

It allows many thin walls and channels to be joined at once, with minimal distortion.

4. Where is friction stir welding most common?

Automotive battery enclosures, aerospace fuselages, and railway aluminum panels.

5. Can both methods be used in one product?

Yes. Brazing for sealed cooling parts and FSW for structural shells is a frequent combination.