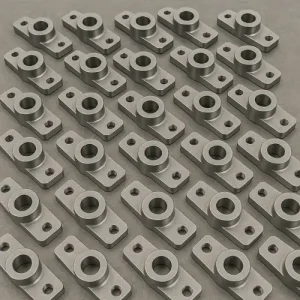

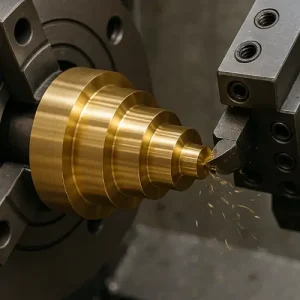

Low-Volume CNC Machining for Functional Parts and Prototypes

Low-volume CNC machining typically refers to short production runs made from real engineering materials, often ranging from a few pieces to a few hundred parts. The exact quantity is rarely fixed. What defines “low-volume” is the context: the design is still evolving, functional validation is ongoing, or the program is not yet stable enough to …