Burrs in CNC Machining: Causes, Risks, and Proven Solutions

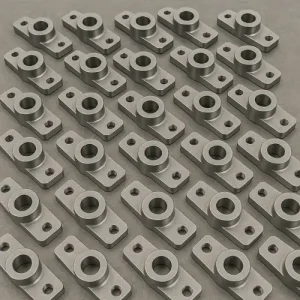

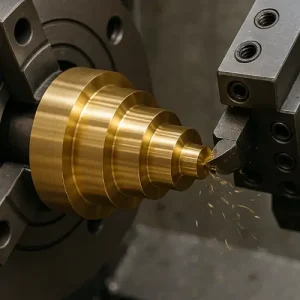

If a part “looks fine” but still won’t assemble, burrs are usually the reason. Dimensions can be on print and surface finish acceptable, but edge condition causes assembly failure. A small exit burr can stop a press-fit, a micro burr on a sealing land can cause a slow leak, and a sliver of copper burr …