In precision manufacturing, the final quality of a machined bore often determines whether a part will perform reliably in service. Conventional machining methods—drilling, boring, or reaming—can bring a hole close to its intended size, but they rarely achieve the exact tolerances, geometry, and surface texture required in demanding applications. This is where the honing process becomes indispensable.

Honing is not just a finishing step but a methodical process that combines controlled abrasive action, specialized machines, and carefully selected tools to refine internal surfaces. From cylinder honing in automotive engines to engine honing during rebuilding, and from hydraulic valve bodies to aerospace actuators, honing is the operation that ensures bores are dimensionally precise and tribologically functional.

This article explains what honing is, why it is required in machined parts, the steps of the honing process, the types of honing operations, and the equipment and tools involved. also examines critical applications, advantages, and limitations, while clarifying the differences between honing vs grinding.

What Is Honing? Definition of the Honing Process

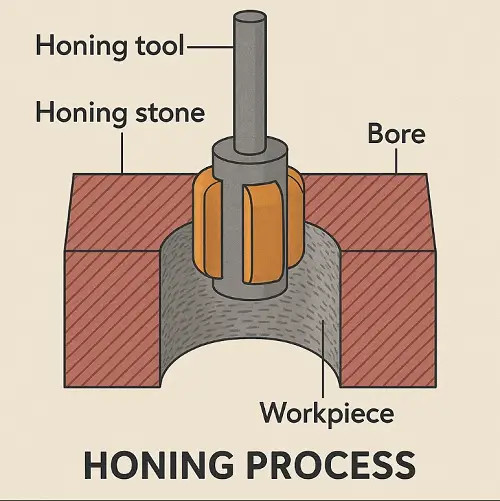

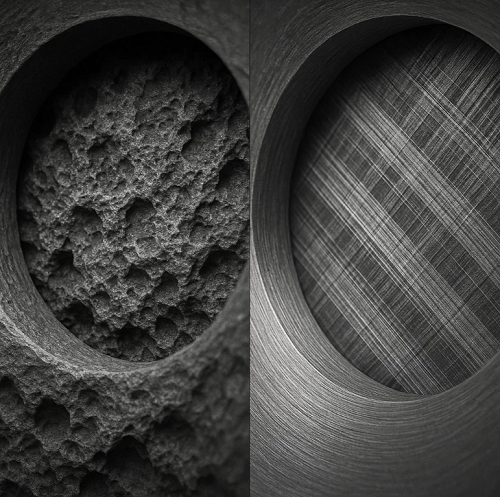

Honing is a precision machining process used to improve the size, geometry, and surface finish of bores. honing employs an expandable honing tool equipped with abrasive stones that both rotate and reciprocate inside the bore, removing material in very small amounts—often just a few microns per pass. The result is a cross-hatch pattern that provides better oil retention and reduces friction between mating surfaces.

Unlike grinding, which removes larger amounts of stock and is widely applied to flat or external surfaces, honing is reserved for final finishing of internal bores. The technique corrects roundness errors, taper, or waviness left from drilling and boring, while simultaneously improving the surface to Ra values as low as 0.1–0.4 µm. For this reason, honing is a key step in manufacturing engine cylinders, hydraulic valve bodies, fuel injection components, and precision gears where both geometry and tribological performance matter.

Why Is Honing Required in Machined Parts?

Most machining operations such as drilling, boring, or reaming can produce a bore close to size, but they rarely meet the tight tolerances or surface quality demanded in high-performance assemblies. A hole that is slightly tapered or out-of-round may still assemble, but in service it could lead to premature wear, leakage, or inefficient operation. Honing is introduced as the last step to eliminate these issues.

Dimensional accuracy

Honing can bring bores within ±0.002–0.005 mm, a level essential in components like injector sleeves or hydraulic spools.

Geometric correction

Multi-stone honing tools average high spots and correct lobes, barrel shapes, or taper left by upstream machining.

Surface optimization

The controlled cross-hatch holds lubricating oil, allowing piston rings in an engine to seat quickly and operate with less scuffing.

Extended component life

Properly honed surfaces reduce wear, lower friction, and extend service intervals for critical systems.

Without honing, many precision parts would meet drawing size but fail functionally in service. This makes it a non-negotiable operation in sectors like automotive, aerospace hydraulics, and fluid power.

Honing Process Steps Explained

The honing process is more structured than simply running a stone through a hole. A complete cycle usually involves:

Workholding and setup.

The component is fixtured to prevent misalignment; in engine blocks, torque plates simulate cylinder head clamping to avoid distortion during honing.

Tool and abrasive selection.

The choice of honing tool—stone type, mandrel design, and grit—depends on the workpiece material and finish requirements. Coarse stones (#80–150 grit) remove stock, while finer stones (#400–600 grit) refine geometry and finish.

Lubrication and flushing.

Specialized honing oil provides cooling and debris removal. Filtration to 5–20 µm is critical to avoid embedding particles back into the surface.

Rough honing.

Initial passes with higher pressure bring the bore close to final size, correcting most form errors.

Finish honing.

Lower pressure and finer abrasives refine the geometry and surface texture.

Plateau honing.

A light final pass or brush removes sharp peaks, producing a surface where piston rings or seals seat quickly while valleys retain oil.

Inspection.

In-process gauging monitors size growth; final checks measure roundness, straightness, and surface parameters like Ra, Rpk, and Rvk.

In cylinder honing, this sequence ensures correct cross-hatch angle (30–45°) for oil control and stable ring sealing. Deviations in angle can cause oil consumption or blow-by, proving why this step is tightly controlled in engine manufacturing.

Types of Honing Operations

Honing can be carried out in different ways depending on production needs and part design.

Manual honing

Performed with handheld or bench-mounted tools, useful for maintenance or repair jobs. While low-cost, results depend heavily on operator skill.

Machine honing

Performed on dedicated honing machines with stable control of spindle speed, stroke length, and expansion pressure. This is standard in production environments.

Single-stone honing

Uses one long stone to contact the bore, suited to small diameters or very deep holes.

Multi-stone honing

Employs several stones around the mandrel, distributing pressure evenly and correcting lobes. This method is essential in automotive cylinder honing.

Internal honing

The most common type, applied to bores in engines, hydraulics, and pneumatic systems.

External honing

Used occasionally on shafts or tubular parts where a controlled texture is required.

Each type of operation is chosen to balance cost, accuracy, and throughput. For example, multi-stone machine honing is indispensable for high-volume engine production, while manual honing remains common in repair shops.

Honing Machines and Their Applications

A honing machine provides the motion, pressure control, and rigidity needed for accurate honing.

Vertical honing machines are common for heavy parts like hydraulic cylinders and engine blocks. They allow gravity-assisted coolant flow and are often more rigid.

Horizontal honing machines are suited to long tubular parts such as gun barrels or hydraulic tubes.

CNC honing machines use servo motors to precisely control spindle speed, stroke rate, and stone expansion. Many include in-process air gauging, enabling automatic size correction.

Multi-spindle machines are used in automotive lines to hone multiple bores simultaneously, cutting cycle times dramatically.

Honing Tools and Abrasive Stones

The selection of honing tools directly determines the success of the process.

Abrasive materials

Silicon carbide (SiC): economical, widely used for cast iron and aluminum components.

Aluminum oxide (Al₂O₃): versatile, suitable for steels.

Diamond: essential for coated engine bores (e.g., Nikasil), ceramics, or very hard alloys; high cutting efficiency at low pressure.

CBN: preferred for hardened steels, offering long tool life and stable cutting.

Mandrels

The expandable mandrel presses stones against the bore wall. Multi-stone mandrels reduce lobing and improve roundness, while single-stone mandrels reach small or deep bores.

Grit size

Coarser grit (80–150) for roughing, medium (220–400) for final sizing, and very fine (>600) or brushes for plateau honing. The grit sequence defines whether the bore reaches functional parameters quickly or requires extended break-in.

Honing oils

Specialized low-viscosity oils flush away swarf and cool the process. Proper filtration keeps debris from embedding into the workpiece.

For example, in engine honing, diamond abrasives with fine grit are required to finish plated bores to Rpk and Rvk targets. In contrast, a cast iron hydraulic cylinder can be honed efficiently with SiC stones and mineral oil, balancing cost with function.

Cylinder Honing in Automotive Manufacturing

Cylinder honing is one of the most critical operations in engine production. After boring, cylinder walls often have taper and surface irregularities. Honing corrects these while generating the cross-hatch pattern necessary for oil film retention.

Geometry correction

Multi-stone mandrels straighten and round the bore, ensuring even contact with piston rings.

Cross-hatch texture

Typically 30–45°, tailored for oil control. Steeper angles promote oil scraping, while shallower angles retain more oil.

Plateau honing

Reduces surface peaks so rings seat faster and friction losses are minimized.

Surface metrics

Specifications often include Ra plus Rpk (reduced peak height) and Rvk (valley depth). Correct balance ensures low oil consumption and durability.

An improperly honed engine cylinder may consume excess oil, lose compression, or wear prematurely. This is why cylinder honing process controls are some of the most stringent in automotive manufacturing.

Engine Honing and Its Importance

Beyond new manufacturing, engine honing is central in engine rebuilding and high-performance machining. When engines are overhauled, cylinders are often rebored oversize to remove wear. Honing then refines the new bore to the exact size of the replacement pistons and creates the surface texture needed for rings to seal.

Shops typically measure the bore, perform boring if necessary, rough hone to near size, then finish hone to within microns of target. A plateau hone may follow to reduce break-in time. Proper honing ensures restored compression, stable oil control, and long engine life. Skipping this step can result in glazed bores, high oil use, and poor performance.

Honing vs Grinding: Key Differences in Machining

Stock removal

Grinding removes larger amounts to shape parts, while honing removes microns to refine size and finish.

Surfaces

Grinding is applied to flats and external diameters; honing specializes in internal bores.

Geometry

Honing corrects lobing, taper, and waviness; grinding typically cannot achieve the same correction inside a bore.

Surface function

Honing creates a textured bore surface that holds oil, while grinding yields a smoother but less functional finish.

In practice, grinding prepares the part close to requirement; honing makes it fully functional for its operating environment.

Applications of the Honing Process in Industry

The honing process finds use wherever precise bores are essential:

Automotive

engine blocks, brake cylinders, fuel injectors.

Hydraulics

cylinder tubes, valve spools, pump housings.

Aerospace

landing gear and actuator components.

Industrial machinery

gears, spindles, and precision sleeves.

Energy sector

compressors, pumps, and oilfield drilling tools.

Advantages and Limitations of Honing

Advantages

Achieves very tight size tolerances.

Improves bore geometry significantly.

Produces engineered surface textures for lubrication.

Compatible with a wide range of metals and coatings.

Limitations

Limited to fine stock removal; inefficient for bulk machining.

Primarily internal bore applications; external use is rare.

Requires stable process control, clean oil, and precise gauging.

Consumable cost can be high with diamond or CBN abrasives.

FAQs About the Honing Process

What tolerances are achievable?

Commonly ±0.002–0.005 mm, depending on length-to-diameter ratio and fixturing.

What abrasives are used in honing tools?

SiC for cast iron and aluminum, Al₂O₃ for steels, diamond for coatings/ceramics, and CBN for hardened steels.

What cross-hatch angle is used in cylinder honing?

Typically 30–45°, adjusted for oil retention versus scraping action.

Why add plateau honing?

It removes sharp peaks, speeds ring seating, and improves wear life.

How does honing differ from lapping or reaming?

Reaming sets bore size but offers little geometry correction. Lapping polishes flat surfaces. Honing combines size accuracy, geometry correction, and functional surface texture.

Conclusion

Honing is essential to ensure that machined parts operate smoothly, resist wear, and maintain long service life. From engine cylinders to hydraulic systems, this process provides the accuracy and surface quality that other methods cannot achieve.

If your project requires precision machining and surface finishing, JeekRapid offers a full range of solutions—including drilling, boring, tapping, reaming, grinding, and honing. Our team delivers high-quality parts with fast turnaround and cost-effective pricing. Upload your CAD files today to get a free quote