Bearings are essential machine components that support shafts, reduce friction, and make rotational or linear motion smoother and more reliable. Bearings can be found in almost every kind of equipment, from small household devices to large industrial machinery. Each type of bearing has unique design features that make the component suitable for specific loads, speeds, and environments. Understanding the characteristics of each type helps engineers and technicians choose the right bearing for optimal performance.

In our machining and assembly validation, we have seen cases where a bearing choice directly determined whether a prototype passed endurance testing. Even minor changes in load conditions or lubrication often showed clear differences in service life, reminding us that bearing performance must be verified in practice, not only on paper.

What Is a Bearing?

A bearing is a mechanical component that supports a rotating or sliding shaft, guiding movement while minimizing friction and wear. Bearings transfer loads between moving parts, allowing smooth motion under both radial and axial forces. By reducing energy loss from friction, bearings increase efficiency, extend machine life, and improve accuracy in operation. Bearings are manufactured with high-precision surfaces and durable materials so that performance remains consistent even under heavy loads, high speeds, or challenging environments. From household fans to aircraft engines, bearings provide the essential link that keeps machinery reliable and efficient.

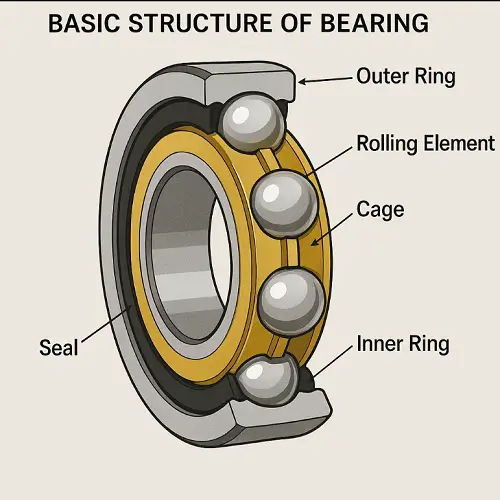

What Are the Main Parts of a Bearing?

A bearing is built from several precision components that work together to provide smooth and reliable motion. The inner ring fits tightly on the rotating shaft and provides a rolling surface for the rolling elements. The outer ring is mounted inside the housing and supports the load transferred by the rolling elements. Rolling elements such as balls, rollers, or needles reduce friction and distribute loads evenly. A cage or retainer keeps the rolling elements evenly spaced and prevents direct contact between them, improving performance and durability. In many designs, seals or shields are added to keep out dust and retain lubrication. The interaction of these components allows the bearing to operate efficiently under a wide range of conditions.

Ball Bearings

Ball bearings are the most widely used type of bearing because of the versatile design and efficient performance. Ball bearings use spherical rolling elements that minimize friction and allow high-speed operation with relatively low noise. In validation tests, small deep-groove ball bearings often reach speeds above 20,000 rpm, while precision spindle bearings can approach 60,000 rpm under proper lubrication. Typical radial clearance values range from 5–25 µm, with options from C2 to C4 depending on application requirements. Ball bearings are commonly applied in electric motors, bicycles, home appliances, and automotive wheels where efficiency, speed, and durability are required.

Roller Bearings

Roller bearings use cylindrical rollers instead of balls, which increases the contact area between the rolling element and the raceway. The line contact design reduces surface stress by roughly 30% compared to ball bearings, which allows roller bearings to support heavier loads. In heavy-duty gearboxes or rolling mills, standard cylindrical roller bearings can handle radial loads exceeding 200 kN without premature fatigue. While roller bearings are effective under high loads, the practical operating speed is usually limited to 8,000 rpm or lower, depending on cage design and lubrication.

Plain Bearings (Bushings)

Plain bearings, also known as bushings, are the simplest type of bearing and do not contain rolling elements. Plain bearings rely on sliding contact between surfaces, usually with lubrication to reduce wear. Plain bearings are compact, cost-effective, and capable of absorbing shocks and vibrations, though the design limits operating speeds compared to rolling bearings. Plain bearings are often found in automotive engines, agricultural machinery, hinges, and other applications that involve low-speed and high-load conditions.

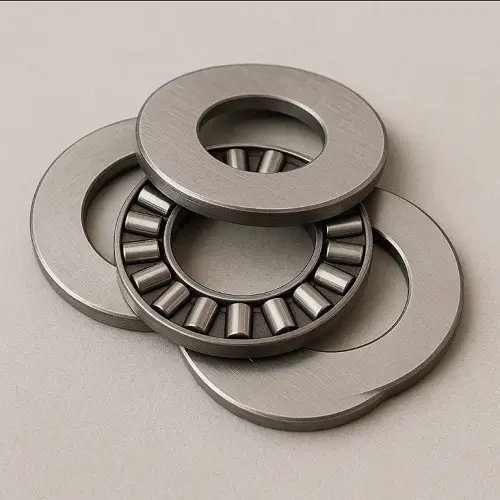

Thrust Bearings

Thrust bearings are designed to support axial loads, either in one direction or in both directions depending on the construction. Thrust ball bearings are used for lighter axial forces and operate smoothly at low to medium speeds, while thrust roller bearings can support heavier axial loads at lower speeds. Thrust bearings require precise alignment during installation because any shaft deflection reduces service life. Push-type ball thrust bearings typically handle ≤2,000 N, while roller thrust bearings are capable of carrying 50,000 N or more. Common applications for thrust bearings include automotive steering systems, turntables, and heavy-duty vertical shafts.

Self-Aligning Bearings

Self-aligning bearings automatically compensate for shaft misalignment or deflection during operation. With a spherical outer raceway and dual rows of rolling elements, self-aligning bearings continue to function smoothly even if the shaft or housing is not perfectly aligned. Self-aligning bearings provide reliable performance in conveyor rollers, textile machinery, and agricultural equipment where alignment is difficult to maintain.

Spherical Roller Bearings

Spherical roller bearings are built for heavy-duty applications and are capable of carrying both high radial and axial loads. The barrel-shaped rollers and self-aligning design allow spherical roller bearings to operate effectively in conditions with misalignment, vibration, and impact. Spherical roller bearings are not designed for extreme speeds, but spherical roller bearings are highly durable in demanding environments. Mining equipment, paper mills, wind turbines, and large industrial fans frequently use spherical roller bearings.

Needle Bearings

Needle bearings use slender rollers with a small diameter, which allows the bearing to carry high radial loads while maintaining a compact structure. Typical needle diameters are only 2–6 mm, with length-to-diameter ratios of 4–10, which explains the high load capacity despite the slim design. During gearbox validation, needle bearings operated reliably up to 12,000–15,000 rpm, but failures occurred quickly when assembly precision was not controlled within micrometer-level tolerances. Automotive transmissions, compressors, motorcycles, and hand tools are common fields where needle bearings are applied.

Comparison Table of Bearing Types

| Bearing Type | Load Direction | Typical Speed Range (rpm) | Load Capacity | Typical Applications |

|---|---|---|---|---|

| Ball Bearing | Radial + light Axial | up to 30,000 | Light–Medium | Motors, wheels, appliances |

| Roller Bearing | Heavy Radial | up to 8,000 | Medium–Heavy | Gearboxes, conveyors |

| Plain Bearing | Radial/Axial (low speed) | < 1,000 | Light–Heavy (with lubrication) | Engines, hinges, pivots |

| Thrust Bearing | Axial only | 3,000–7,000 | Light–Medium (ball) / Heavy (roller) | Steering, turntables |

| Self-Aligning Bearing | Radial + some Axial | up to 12,000 | Medium | Conveyors, agricultural use |

| Spherical Roller | Radial + Axial (heavy) | up to 5,000 | Heavy | Mining, mills, fans |

| Needle Bearing | Radial (compact) | up to 15,000 | Medium | Transmissions, compressors |

How to Choose the Right Bearing?

After reviewing the main categories of bearings and their characteristics, the next step is to understand how to select the correct bearing for a specific application. Bearing selection is not based on a single factor but rather on a combination of operating conditions. The most important considerations include load, speed, accuracy, rigidity, and other environmental or installation requirements.

Load Conditions

When the main force is radial, radial bearings such as deep groove ball bearings or cylindrical roller bearings are preferred. When the main force is axial, thrust bearings or angular contact ball bearings are more suitable. For combined radial and axial loads, tapered roller bearings or spherical roller bearings provide a better balance. Light loads benefit from smaller high-speed bearings, while heavy loads require bearings with larger rolling elements and higher rigidity.

Speed

The speed of operation directly affects bearing choice. Ball bearings are commonly used in high-speed applications due to low friction and quiet performance. Roller bearings are better suited for medium and low speeds under heavy loads. For very high-speed spindles, angular contact ball bearings or hybrid ceramic bearings are often selected to maintain stability at extreme speeds. In precision spindles, maximum permissible speed can exceed 50,000 rpm, while heavy-duty rollers typically remain below 10,000 rpm.

Accuracy

Applications involving machine tool spindles or precision measuring equipment require high-accuracy bearings with strict tolerance grades, such as P5 or P4. Standard industrial machinery generally uses P6 or normal-grade bearings. Accuracy influences vibration, noise, and the overall precision of the system. For example, spindle systems often demand radial runout less than 3 µm to guarantee machining accuracy.

Rigidity

In equipment where shaft deflection must be minimized, bearing rigidity is a critical factor. Roller bearings and preloaded angular contact ball bearings provide greater stiffness, making them ideal for cutting machines, grinding spindles, and applications demanding consistent precision under heavy forces.

Other Considerations

Design limitations such as restricted installation space often require compact solutions like needle bearings or thin-section bearings. Environmental conditions including high temperatures, moisture, dust, or corrosive media may call for sealed designs, stainless steel bearings, or ceramic rolling elements. For agricultural machinery, bearing designs are often validated to deliver 10,000–20,000 hours of service life with proper lubrication and sealing.

note: Poor surface finish, insufficient lubrication, or mismatched materials can cause severe wear and even galling under load.

Conclusion

Bearing selection is always a balance between mechanical requirements and operating conditions. Our validation work has shown that details such as preload settings, housing tolerances, or surface finish often decide whether a bearing runs reliably or fails early. These lessons confirm that real-world testing is the most valuable step in confirming theoretical design choices.

JeekRapid provides one-stop precision CNC machining services for custom components, prototypes, and low-volume production. Whether a project involves bearing housings, shafts, or other precision parts, JeekRapid can deliver tight tolerances and consistent quality. Upload your CAD files or drawings today to request a quote and get professional support for your next engineering project.

FAQ

Which bearing is best for high speed?

Ball bearings and angular contact ball bearings are best suited for high-speed operation because of low friction and stability. Hybrid ceramic bearings are also widely used in very high-speed spindles.

Which bearing is most commonly used?

Ball bearings are the most commonly used because of their versatility, ability to handle both radial and light axial loads, and suitability for a wide range of machinery.

Which bearing is used in cars?

Automobiles typically use ball bearings and tapered roller bearings. Wheel hubs rely on tapered roller bearings for combined radial and axial loads, while electric motors and accessories often use ball bearings.

What bearing is used for heavy loads?

Roller bearings, tapered roller bearings, and spherical roller bearings are commonly selected for heavy-duty applications requiring high load capacity and rigidity.

What bearing is best when space is limited?

Needle bearings are ideal for compact installations because of their thin cross-section and high radial load capacity.

What are the main parts of a bearing?

The inner ring, outer ring, rolling elements, and cage form the core of a bearing. Seals or shields are often added to retain lubrication and block contaminants, ensuring long-term performance.

About the Author

This article was written by the engineering team at JeekRapid, a precision manufacturing company based in Dongguan with over 20 years of experience in CNC machining, injection molding, sheet-metal fabrication, and rapid prototyping. JeekRapid’s engineers specialize in tolerance control, surface finishing, and material selection, helping clients across automotive, aerospace, and medical industries develop reliable components from prototype to low-volume production.