Polyvinyl chloride (PVC) is one of the world’s most widely used thermoplastics, accounting for nearly 20% of global polymer demand. PVC plastic offers a balance of strength, flame resistance, chemical durability, and affordability, which explains its use in construction, healthcare, electrical systems, and consumer goods. The adaptability of PVC comes from its ability to be modified with additives, resulting in rigid, flexible, transparent, or opaque formulations.

What is PVC Plastic?

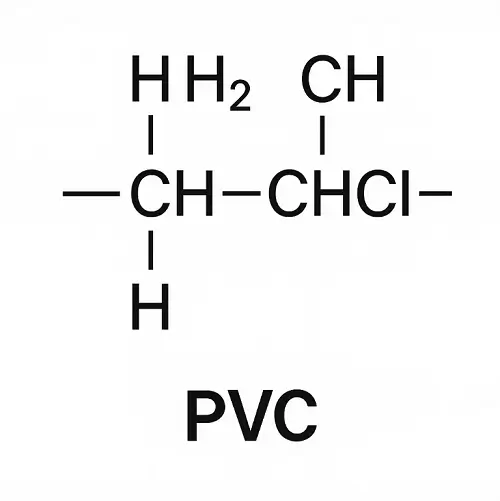

PVC refers to polyvinyl chloride, a polymer created through the polymerization of vinyl chloride monomer (VCM). Its repeating molecular structure –CH₂–CHCl– contains chlorine atoms, which account for about 57% of its mass. The chlorine content enhances flame resistance and chemical stability, while also making PVC heat-sensitive and more complex to recycle compared with polyolefins.

What is PVC Plastic Made Of?

Raw Materials

PVC originates from two simple feedstocks: ethylene and chlorine. Ethylene is produced from petroleum or natural gas, while chlorine is obtained from common salt through electrolysis. These react to form vinyl chloride monomer, the base compound used in PVC production.

Polymerization Process

Vinyl chloride monomers are joined into long polymer chains through suspension, emulsion, or bulk polymerization. Suspension polymerization is the most common industrial method, yielding a white resin powder that forms the foundation for PVC products.

Additives in PVC

Pure PVC resin is brittle and thermally unstable, so additives are essential. Stabilizers protect against heat and UV degradation, plasticizers create flexibility, fillers reduce cost, impact modifiers improve toughness, and pigments provide color. These modifications allow PVC to serve in applications ranging from rigid structural profiles to flexible tubing.

What Are the Properties of PVC Plastic?

Density of PVC

PVC has a density of 1.35–1.45 g/cm³, higher than most commodity plastics. This density contributes to rigidity and long service life in construction applications. The drawback is added weight, which increases transportation costs. Engineers offset this by designing thinner walls without sacrificing performance.

Tensile Strength of PVC

Rigid PVC typically exhibits tensile strength between 40–60 MPa, comparable to ABS plastics. This makes PVC strong enough for pressurized water pipes and load-bearing window profiles. In structural applications requiring greater capacity, PVC can be reinforced with fibers or used in composites.

Modulus of Elasticity

The modulus of elasticity for PVC ranges from 2.4–4.1 GPa, which explains its stiffness and dimensional stability. Rigid PVC maintains shape under stress, making it suitable for long-term use in building products. Where flexibility is needed, engineers use flexible PVC or elastomer-modified blends.

Heat Resistance of PVC

PVC softens between 100–150 °C and decomposes above 200 °C. Standard grades are limited to service temperatures up to 60 °C. This excludes use in hot water systems. CPVC, developed by chlorination, extends performance to 90–110 °C. In demanding conditions, multilayer composites also enhance thermal stability.

Chemical Resistance

PVC resists acids, alkalis, and salts, making it reliable for industrial piping. Performance decreases when exposed to aromatic hydrocarbons, ketones, or chlorinated solvents. For these environments, protective linings or fluoropolymer substitutions are used.

What Are the Types of PVC Plastic?

Rigid PVC (uPVC)

Rigid PVC, also called unplasticized PVC, is stiff and dimensionally stable, with tensile strength up to 70 MPa. It is widely used for pipes, window frames, and exterior cladding. The absence of plasticizers increases flame resistance but also makes the material brittle in cold weather. To overcome this, manufacturers add impact modifiers or recommend alternative plastics such as HDPE in very cold regions.

Flexible PVC

Flexible PVC is achieved by adding plasticizers, which lower intermolecular forces and allow elongation beyond 200%. Flexible PVC is common in cable insulation, flooring, synthetic leather, and especially medical tubing and IV bags. Its transparency and ability to withstand sterilization have kept it dominant in healthcare. The limitation of plasticizer migration is addressed through non-phthalate additives and multilayer tubing systems.

Chlorinated PVC (CPVC)

Chlorinated PVC increases chlorine content to about 65%, improving heat resistance to 90–110 °C. CPVC retains mechanical strength similar to PVC but is better suited for hot water and fire sprinkler systems. CPVC has replaced copper in many residential plumbing systems because of its resistance to corrosion and scaling. The trade-off is higher cost and specialized installation requirements.

UPVC (Unplasticized PVC)

UPVC is widely used in the construction industry for windows, doors, and siding. UPVC profiles combine rigidity, recyclability, and weather resistance. In European markets, UPVC window frames dominate because they reduce energy loss by up to 30% when paired with double glazing. Cold-weather impact resistance remains a limitation, improved with stabilizers and co-extruded protective layers.

What Are the Applications of PVC Plastic?

PVC in Construction

Nearly 60% of global PVC output goes into construction. Pipes, siding, roofing membranes, and window frames rely on PVC’s strength, corrosion resistance, and low cost. The material supports large-scale infrastructure projects and residential construction worldwide.

PVC in Medical Devices

Flexible PVC plays a critical role in healthcare, appearing in blood bags, dialysis tubing, and IV lines. Its ability to remain transparent and flexible after sterilization gives it an edge over many alternatives. The adoption of non-phthalate plasticizers has strengthened PVC’s compliance with medical regulations.

PVC in Electrical Systems

PVC is widely used for wire insulation, cable sheathing, and conduits. Flame resistance, electrical properties, and affordability make PVC a preferred choice for both residential and industrial wiring systems.

PVC in Packaging and Consumer Goods

PVC appears in blister packs, shrink films, transparent bottles, flooring, toys, wallpapers, and synthetic leather. It often competes with PET, PE, or PU, but its balance of durability and cost keeps it popular.

Learn more about our Plastic Machining Services.

How is PVC Processed?

Extrusion of PVC

Extrusion is the most common processing method, producing pipes, profiles, and sheets. Stabilizers are critical because PVC is heat-sensitive, and twin-screw extruders are often used to achieve thorough mixing of additives. The continuous extrudate is cut to length for use in construction and industrial systems.

Injection Molding of PVC

Injection molding shapes PVC into fittings, connectors, and small precision parts. Processing requires careful control of temperature, as PVC decomposes if overheated. Low-shear screw designs are often used to minimize material degradation.

CNC Machining of PVC

Rigid PVC sheets and rods can be machined using CNC milling or turning. CNC machining is especially valuable for prototypes and low-volume production where extrusion or molding is not cost-effective. Machined PVC is used in housings, fixtures, and custom components. JeekRapid provides precision CNC machining of PVC with tolerances down to ±0.01 mm, and can supply inspection reports and material certifications for industries that require traceability.

Table – Comparison of PVC Processing Methods

| Processing Method | Typical Products | Key Advantages | Challenges |

|---|---|---|---|

| Extrusion | Pipes, profiles, sheets | High throughput, continuous shapes | Requires stabilizers, heat-sensitive |

| Injection Molding | Fittings, connectors, valves | Precise, repeatable, complex designs | Narrow processing window, degradation risk |

| CNC Machining | Prototypes, fixtures, low-volume parts | Tight tolerances, flexible for small runs | Higher waste, slower than molding |

What Are the Disadvantages of PVC and How Are They Addressed?

Brittleness at Low Temperatures

Rigid PVC loses impact resistance in freezing conditions because polymer chains become less mobile. Outdoor pipes can crack, leading to leaks and failures. Manufacturers add impact modifiers to improve toughness, and in severe climates, engineers often switch to PE or PEX for ductility.

Limited Heat Resistance

Standard PVC softens above 60 °C, restricting its use in hot water systems. Continuous thermal stress can deform pipes and weaken fittings. CPVC addresses this issue, and hybrid systems often combine CPVC for hot lines with PVC for cold water to balance performance and cost.

Plasticizer Migration

Flexible PVC depends on plasticizers for softness, but over time these can migrate to the surface or volatilize. The result is reduced flexibility and potential safety concerns. Non-phthalate plasticizers and multilayer tubing designs have largely resolved this issue in sensitive applications such as healthcare.

Environmental Concerns

Chlorine content complicates recycling and disposal. Uncontrolled burning releases hydrochloric acid and dioxins. Mechanical recycling of rigid profiles and chemical depolymerization back to monomers are advancing solutions. Controlled incineration with flue gas treatment is also used for safe disposal.

PVC vs Other Plastics

| Material | Density (g/cm³) | Tensile Strength (MPa) | Heat Resistance | Cost | Notes |

|---|---|---|---|---|---|

| PVC | 1.35–1.45 | 40–60 | ~60 °C | Low | Pipes, profiles, flooring |

| CPVC | 1.55 | 55–75 | ~110 °C | Medium | Hot water, fire protection |

| PE | 0.91–0.96 | 20–30 | ~60 °C | Very low | Flexible, lightweight |

| ABS | 1.04 | 40–50 | ~80 °C | Medium | High toughness, less chemical resistant |

| PP | 0.90–0.92 | 25–35 | ~90 °C | Low | Lightweight, fatigue resistant |

Conclusion

PVC plastic is a versatile, durable, and cost-effective material that underpins modern industry. Its adaptability across rigid and flexible forms makes it suitable for construction, healthcare, electrical systems, and consumer goods. Limitations such as brittleness, thermal constraints, and recycling difficulties are managed through material modifications, CPVC substitution, impact modifiers, and new recycling methods.

JeekRapid provides CNC machining and prototyping services for PVC and other engineering plastics. Whether rigid PVC sheets or flexible PVC parts are required, JeekRapid delivers tolerances as tight as ±0.01 mm with fast turnaround. Upload your CAD drawing to request a free quote.

Frequently Asked Questions (FAQ)

Can PVC plastic be bent in place?

Flexible PVC can bend easily, while rigid PVC usually requires heating or fittings.

What is PVC plastic sheet used for?

PVC sheets are used in cladding, signage, and protective covers.

What is the melting temperature of PVC pipe?

PVC softens around 150 °C and decomposes above 200 °C.

Is PVC a thermoplastic?

Yes, PVC softens with heat and hardens when cooled.

What products are made of PVC?

Common examples include pipes, profiles, flooring, medical tubing, and packaging films.

What are the disadvantages of PVC?

Key issues include brittleness in cold climates, limited heat resistance, plasticizer migration, and recycling challenges.

Why is PVC used in construction?

Because of its durability, low cost, flame resistance, and ability to replace more expensive materials like metals.