Polystyrene (PS) is one of the most widely used thermoplastics in industrial production. Since its commercialization by BASF in Germany in the 1930s, this material has been widely adopted in industries such as packaging, home appliances, medical devices and prototyping due to its high rigidity, transparency and good processability. While it is commonly used in everyday consumer products such as disposable cup boxes, foam packaging and other lightweight products, PS is also one of the common materials used by engineers during the mold trial and validation phase of mold manufacturing due to its low shrinkage, high gloss and excellent dimensional stability.

JeekRapid often uses different grades of polystyrene, such as GPPS and HIPS, in the mold development process for structural parts such as optical parts, electronic housings, and cosmetic caps. PS is a stable, cost-effective material for projects that require molding speed, dimensional accuracy and surface finish.

What is Polystyrene (PS)

Polystyrene is a non-crystalline thermoplastic made by polymerizing styrene monomer. Its molecular structure contains benzene rings that give the material high rigidity and optical transparency. The material softens rapidly when heated and regains rigidity when cooled. It can be molded with multiple heats, making it suitable for prototype and high-volume injection molded part production.

Material Properties and Classification

Polystyrene is a non-crystalline thermoplastic made by polymerizing styrene monomer. The material contains a benzene ring structure in the molecular chain, which gives it high rigidity and good optical transparency. It softens rapidly when heated and regains its hardness when cooled. It can be reheated and remolded several times and is suitable for prototype, appearance and batch injection molded parts.

There are two main types in industry:

-

GPPS (General Purpose Polystyrene): Transparent, highly rigid but brittle, commonly used for optical or appearance parts;

-

HIPS (Impact Polystyrene): A rubber component is added to the polymer to improve toughness and is used for appliance housings, toys, packaging containers, etc.

With a glass transition temperature of about 100°C and a density of about 1.05 g/cm³, polystyrene has excellent fluidity and is easy to fill complex or thin-walled structures. These characteristics allow for short molding cycles and easy control of accuracy, making it ideal for use as a production material for validation molds and batch molds.

Main Performance Parameters

| Performance Items | Typical Values | Units | Engineering Description |

|---|---|---|---|

| Density | 1.04-1.06 | g/cm³ | Lightweight Rigid Material |

| Tensile Strength | 45-55 | MPa | Highly Rigid but Brittle |

| Bending Modulus | 3.0-3.5 | GPa | Excellent Dimensional Stability |

| Barrier Impact Strength | 20 -25 | J/m | GPPS low, HIPS high |

| Heat distortion temperature | 90-100 | °C | Suitable for low and medium temperatures |

| Forming shrinkage | 0.3-0.7 | % | Precision mold friendly |

| Water absorption (24h) | <0.1 | % | No pre-drying required |

| Light transmission | 88-92 | % | Good optical transparency |

Overview of Advantages and Disadvantages

The greatest advantages of PS are its ease of processing, dimensional stability and high surface gloss. The high flowability allows smooth mold filling in thin-walled structures, fast cooling and short molding cycles. Small dimensional changes and low shrinkage make it ideal for molds with tight tolerances. At the same time, the low material cost makes it suitable for mass production and mold prototyping.

Shortcomings are also more obvious: pure GPPS brittleness, limited impact resistance; easy to fracture under stress or heat conditions. Its heat resistance is not as good as that of PC or ABS, and its long-term use temperature generally does not exceed 90°C. In addition, it is sensitive to some solvents and prone to stress cracking. For products requiring strength or weathering resistance, HIPS or PS/ABS blends are commonly used as substitutes.

Polystyrene in Several Applications

Polystyrene does not exist in a single form in industry, but is often modified or molded into the following types, depending on the application:

Solid or Rigid PS (GPPS): Mainly used for transparent housings, instrument covers, optical windows, and other parts that require high gloss and rigidity. The surface of the parts is flat and can be high-gloss polished or printed.

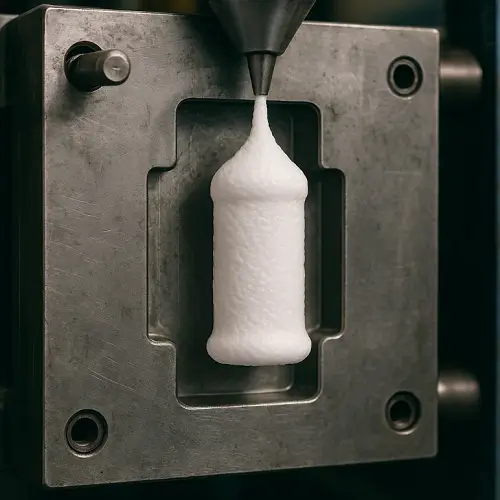

Foam PS (EPS): Obtained by foam molding, commonly used in packaging, cushioning, heat insulation and thermal insulation. It is lightweight and has a high energy-absorbing capacity, making it a cost-effective material in the construction and packaging fields.

Film type PS: Extruded into thin sheets or films, used for food trays, printed labels, transparent covers, etc. The material is highly flat and dimensionally stable, and is suitable for vacuum molding and printing.

Composite PS material: Polystyrene is used as the matrix, and glass fiber or mineral filler is added to improve stiffness and heat resistance. Mostly used for structural and functional components.

Copolymerized polystyrene: Styrene can be copolymerized with other monomers to form a variety of engineering plastics, such as ABS, SAN, HIPS, etc. These materials retain the fluidity of PS, while significantly improving impact and chemical resistance.

Mold Shrinkage and Dimensional Control

The low shrinkage (0.3-0.7%) of polystyrene is one of its most attractive features in mold design.

JeekRapid accurately compensates for cavity dimensions during mold making for different material grades and wall thicknesses.

For GPPS, shrinkage compensation is typically in the range of 0.004-0.005 mm/mm; HIPS is a bit higher, around 0.006-0.007 mm/mm.

Mold temperature control has a significant impact on dimensional stability. Uneven cooling distribution can lead to localized warping or distortion.

JeekRapid’s approach is to anticipate shrinkage distribution by balancing the cooling water lines, controlling steel temperature differences to within ±2°C, and performing Moldflow analysis during the mold design phase. For multi-cavity molds, gate sizes and holding curves are adjusted according to the balance of flow paths to ensure consistent molding across cavities.

Surface Gloss and Mold Polishing

The surface replication of PS is very good, which can directly reflect the cavity finish.

For optical or cosmetic parts, JeekRapid typically uses S136 or 2316 mold steel, polished to SPI A1-A2 grade.

This highly mirrored material provides excellent clarity and reflection in PS molding.

Mold temperatures of 50-60°C produce the desired gloss, while low temperatures (e.g., below 40°C) are prone to fogging or microwaving.

During production, engineers use ionic air to remove dust between mold cycles to prevent surface marks caused by dust spots.

PS is not suitable for painting or plating, but it can be silk-screened and hot-stamped, and works especially well on cosmetic covers, display housings, and other exterior parts.

Injection Molding Defects and Solutions

PS is highly fluid but also prone to problems. Common surface defects are flow marks, spin marks or fusion lines.

These problems are often related to uneven temperatures or unbalanced mold filling.

JeekRapid’s experience with these problems is as follows:

When surface flow marks are detected, increase the mold temperature to 55-65°C;

If the problem persists, increase the injection rate and maintain a steady back pressure to smooth the melt front;

Gates should be placed as close to the center as possible, as small or off-set gates can cause ripples to form;

At the same time, a 0.02 – 0.03 mm venting slot must be provided at the end of the part to prevent gas trapping.

For HIPS materials, lowering the shear rate can also reduce rubber phase separation.

JeekRapid conducts real-time visual inspections during production and fine-tunes pressure profiles and temperature control zones based on mold flow results to ensure that parts are free of flow marks and shadows.

PS vs. ABS

| Parameters | Polystyrene (PS) | ABS |

|---|---|---|

| Flowability | Excellent | Medium |

| Shrinkage | 0.3-0.7 % | 0.5-0.9 % |

| Mold Temperature | 40-60°C | 60-80°C |

| Impact Resistance | Low | High |

| Surface Gloss | Very High | Medium |

| Paintability | Poor | Excellent |

| Fast molding speed | Medium | |

| Low cost | Medium |

In moldmaking, PS is often used for exterior parts, optics, and prototyping;

and ABS is better suited for parts that require strength, painting, and structural stability.

JeekRapid also often uses PS/ABS blends for a combination of glossy appearance and impact resistance.

Typical Applications

Polystyrene is commonly used in a variety of applications, including consumer electronics, medical, packaging and prototyping.

| INDUSTRY | APPLICATION EXAMPLES | Features |

|---|---|---|

| Consumer products | Cosmetic lids, display cases, packaging parts | High gloss, low cost, fast-paced |

| Electronics and appliances | Remote control housings, instrument covers | Dimensionally stable, easy to mold |

| Medical and laboratory | Petri dishes, test tubes | Transparent, clean |

| Stationery and toys | Model parts, pen cases | Easy to work with, can be colored |

| Prototypes | Molded test pieces, validation pieces | High precision, good polish |

JeekRapid’s PS Injection Molding Capabilities

JeekRapid has extensive experience in precision injection molding of GPPS and HIPS.

During the mold design phase, the company will develop cooling, venting, and gate layouts that are tailored to the product structure, ensuring uniform shrinkage, non-marking surfaces, and short molding cycles.

Key capabilities include:

-

Multi-cavity mold balancing and Moldflow simulation analysis;

-

Optical grade mold SPI A1-A2 polishing;

-

±0.02 mm accuracy mold machining and dimensional control;

-

PS/ABS co-molding and assembly;

-

Mold temperature synchronization and pressure monitoring to ensure batch consistency.

Each project is accompanied by a DFM manufacturability analysis and material recommendations to ensure a well-structured and stable mold.

Frequently Asked Questions (FAQ)

Q1: What is the typical shrinkage rate of polystyrene?

Usually between 0.3-0.7%, depending on thickness and material grade.

Q2: Do I need to dry PS before injection molding?

No. The material has low hygroscopicity and can be injection molded directly.

Q3: How to get a high gloss surface?

Keep the mold temperature at 55-60°C, use mirror-polished molds and maintain stable holding pressure.

Q4: Why are there flow marks?

Mainly due to uneven mold filling or insufficient venting. Adjusting the gate position or increasing the injection speed can improve the situation.

Q5: Can PS be used with ABS?

Yes, PS/ABS blends are often used for shell parts to maintain luster and improve strength.

References and Quotations

Some of the performance data in this article is based on BASF Styrolution and ChiMei GPPS/HIPS technical data, and is intended to be used as a reference for material parameters only.

This article was written by JeekRapid’s engineering team, with more than 10 years of experience in mold making and injection molding, and combines actual test molds with mass production data.

JeekRapid provides rapid tooling and injection molding services for a wide range of plastic materials such as polystyrene (PS), ABS, and PC.

You can upload a 3D file or drawing, and we will provide a manufacturability analysis (DFM) and a formal quote within 24 hours.