A milling machine is one of the most versatile tools in precision manufacturing. By rotating a cutting tool at high speed while feeding a workpiece along multiple axes, milling machines can produce flat surfaces, contoured profiles, slots, pockets, and complex 3D geometries with tight tolerances. Compared to turning—where the workpiece rotates—milling is better suited for prismatic parts and intricate details.

In modern production, CNC milling machines have largely replaced manual machines, offering automation, repeatability, and higher efficiency. This has made milling indispensable in industries where precision and repeatability are critical.

What is a Milling Machine?

A milling machine is a machine tool that removes material from a workpiece by advancing a rotary cutter into it. Depending on the configuration, the cutter can move along one or multiple axes, enabling the creation of complex geometries with high dimensional accuracy.

Modern CNC milling machines are equipped with automated control systems that regulate spindle speed, feed rate, and tool movement according to a programmed toolpath. This allows manufacturers to achieve consistent results, even for complex multi-surface parts.

Historically, manual milling machines were limited to basic operations, but today’s CNC systems offer features such as multi-axis machining, automatic tool changers, high-speed cutting, and adaptive feed control. These advancements make milling machines essential in aerospace, automotive, medical device, and precision engineering sectors.

Working Principle of a Milling Machine

The milling process involves a rotary cutting tool mounted on a spindle. The tool removes material as the workpiece moves along the X, Y, and Z axes. In CNC milling, this movement is controlled by programmed toolpaths, ensuring consistent quality and repeatability.

Key process parameters include:

-

Cutting speed (Vc) – Based on material and cutter type.

-

Feed rate (F) – The linear speed at which the cutter engages the workpiece.

-

Depth of cut (ap) – The amount of material removed in one pass.

Precision CNC milling can achieve tolerances of ±0.01 mm to ±0.05 mm, with surface finishes as fine as Ra 0.8 µm for finishing operations.

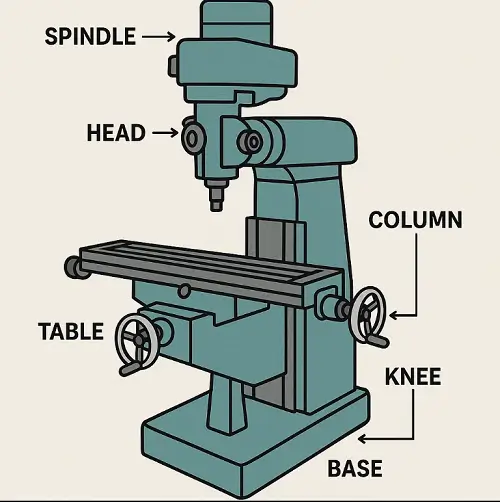

Main Parts of a Milling Machine

Spindle

Holds and rotates the cutting tool at high speeds.

Table

Supports the workpiece and allows controlled movement along the X and Y axes.

Knee

A vertically adjustable support that carries the table and saddle.

Column

Provides structural support for the spindle and knee assembly.

Saddle

Mounted on the knee, allows perpendicular movement of the table relative to the spindle axis.

CNC Controller

Controls programmed movements, tool changes, and machining parameters.

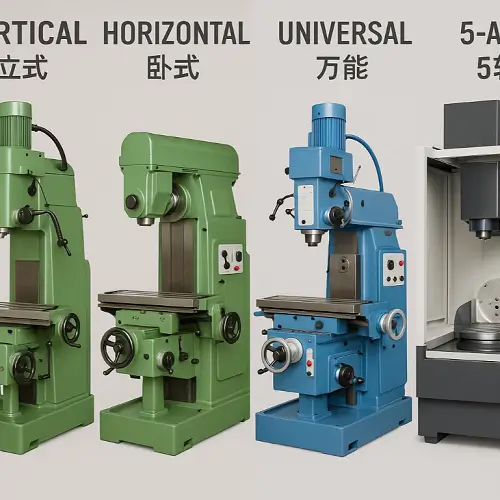

Types of Milling Machines

Vertical Milling Machine

The spindle is vertical; ideal for slotting, face milling, and contouring.

Horizontal Milling Machine

Spindle mounted horizontally; suitable for heavy-duty cutting and material removal.

Universal Milling Machine

Combines vertical and horizontal capabilities; flexible for complex setups.

Turret Milling Machine

Features a movable spindle head for machining at various angles.

5-Axis CNC Milling Machine

Offers simultaneous movement in five axes, enabling complex, multi-surface machining in one setup.

Types of Milling Operations

Face Milling

Produces flat surfaces using a cutter with multiple teeth.

End Milling

Uses a cutter with end teeth to produce slots, profiles, and pockets.

Climb Milling

Cutter rotates in the same direction as feed; provides a better surface finish but requires rigid setups.

Conventional Milling

Cutter rotates opposite to feed; offers stability when machining harder materials.

Materials Suitable for Milling

Aluminum

Excellent machinability, ideal for aerospace and automotive components.

Stainless Steel

Requires rigid setups, lower cutting speeds, and coolant to prevent work hardening.

Brass

Allows high-speed milling with excellent surface finish.

Titanium

Demands optimized toolpaths and coated carbide tools due to low thermal conductivity.

Accuracy Reference for Different Milling Types

The achievable accuracy of a milling machine depends on its design, build quality, and maintenance. Below is a general reference for common milling machine categories:

| Machine Type | Typical Tolerance Range | Surface Finish (Ra) | Common Applications |

|---|---|---|---|

| Entry-Level CNC Vertical Mill | ±0.05 mm | 3.2–1.6 µm | General parts, low-volume production |

| Standard 3-Axis Machining Center | ±0.02 mm | 1.6–0.8 µm | Automotive components, mold bases |

| High-Precision 3-Axis Machining Center | ±0.01 mm | 0.8–0.4 µm | Aerospace brackets, precision fixtures |

| High-Precision 5-Axis Machining Center | ±0.005–0.008 mm | 0.4–0.2 µm | Medical implants, turbine components |

Engineering Notes:

-

Accuracy is influenced by tool wear, workholding stability, and environmental control.

-

Ultra-precision work often requires temperature-controlled environments.

-

Regular calibration ensures the machine maintains its tolerance capabilities.

Applications of Milling Machines

-

Automotive – Engine components, transmission housings, precision fixtures.

-

Aerospace – Structural parts, brackets, turbine components.

-

Prototype Manufacturing – Production-grade prototypes for functional testing.

-

Small Batch Production – Flexible runs without the cost of dedicated tooling.

Milling Machine vs Other Machines

Milling vs Lathe

Milling removes material with a rotating cutter; a lathe rotates the workpiece for material removal.

Milling vs Drilling

Milling can cut along multiple axes, while drilling produces only cylindrical holes.

Milling vs Grinding

Grinding achieves ultra-fine surface finishes; milling is faster for bulk material removal.

How JeekRapid Provides CNC Milling Services

JeekRapid operates CNC milling machines ranging from high-speed vertical mills to precision 5-axis centers, capable of tolerances as tight as ±0.005 mm. Our team selects optimal tooling, parameters, and setups for each project, ensuring cost-effective production without compromising quality.

Upload your CAD files to receive a detailed quotation within 24 hours, complete with pricing, lead time, and material certification options.

Frequently Asked Questions (FAQ)

1: What is the difference between a milling machine and a lathe?

A milling machine uses a rotating cutter to remove material, ideal for flat and complex surfaces. A lathe rotates the workpiece to create cylindrical shapes.

2: What materials can be machined on a milling machine?

Commonly used materials include aluminum, steel, stainless steel, brass, titanium, plastics, and composites.

3: How accurate is a CNC milling machine?

Standard CNC milling machines hold ±0.02 mm, while high-precision models can reach ±0.005 mm under controlled conditions.

4: Is CNC milling suitable for prototype manufacturing?

Yes. CNC milling produces production-grade accuracy, making it ideal for functional prototypes.

5: What factors affect the cost of CNC milling?

Machine type, material, part complexity, tolerance requirements, and production volume all influence cost. Optimized toolpaths can reduce cycle time and expense.