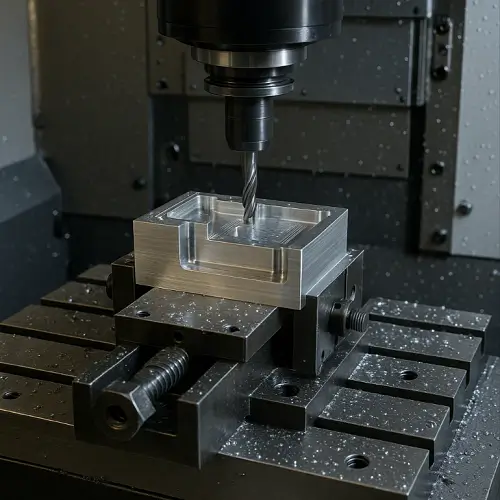

In today’s fast-paced product development environment, manufacturers are no longer designing solely for high-volume production. Increasingly, engineers and procurement teams seek solutions that allow for agility, risk reduction, and real-world testing—without committing to costly tooling or large inventories. This is where low volume CNC machining offers a strategic advantage. Whether it’s a functional prototype, pre-production validation batch, or small-scale specialty run, low volume manufacturing ensures parts are delivered with precision, speed, and material integrity.

This article explores the full scope of low volume CNC machining from an engineering perspective—covering process selection, material behavior, dimensional standards, cost drivers, and real-world application strategies.

What Is Low Volume CNC Machining?

Low volume CNC machining refers to the precision manufacturing of small quantities of parts, typically ranging from 1 to 1000 units. Unlike mass production, which prioritizes cost-per-unit reduction at scale, low volume machining focuses on flexibility, speed, and responsiveness—often serving pre-production stages such as prototyping, design validation, or limited market testing. In engineering terms, low volume machining fills the gap between one-off prototyping and full-scale production.

This approach enables engineers to avoid large upfront tooling investments, iterate faster, and produce high-precision parts from production-grade materials. Industries such as robotics, aerospace, automotive, and medical technology rely heavily on small batch production to reduce risk and accelerate time-to-market

Industries and Use Cases

Low volume CNC machining supports critical applications across multiple sectors:

- Medical Devices: Custom housings, orthopedic trial implants, or diagnostic components.

- Aerospace: Cabin equipment brackets, sensor housings, and UAV frames.

- Robotics & Automation: Linear guide mounts, drive enclosures, control brackets.

- Consumer Electronics: Limited-edition casings, internal support frames.

- Automotive R&D: Gearbox prototypes, aluminum heat sinks, or engine mounts.

Each industry values short-run capabilities not only for speed, but also for their ability to deliver final-material performance and real-world testing.

Material Selection for Small Batch CNC Machining

Material choice is a critical engineering decision in low volume projects. It affects not only machinability but also performance, lead time, and unit cost.

| Material | Type | Ideal Applications | Notes on Machinability |

|---|---|---|---|

| 6061 Aluminum | Metal | UAV parts, enclosures, brackets | Excellent machinability |

| 7075 Aluminum | Metal | Structural aerospace parts | High strength, lower machinability |

| 304 Stainless | Metal | Food/medical components | Moderate hardness, corrosion resistant |

| 316 Stainless | Metal | Marine, surgical, fluid connectors | High corrosion resistance |

| 17-4 PH Stainless | Metal | High-strength components, actuators | Requires precise feeds/speeds |

| POM (Delrin) | Plastic | Gears, bearings, sliding components | Low friction, easy to machine |

| Nylon | Plastic | Cable holders, wear-resistant parts | Slightly hygroscopic |

| PC / ABS | Plastic | Consumer device housings | Balance of rigidity and toughness |

Material availability in bar stock or sheet form also determines feasibility for short lead times.

Dimensional Considerations and Tolerances

Low volume CNC parts typically range in size from 10 mm to 500 mm. Dimensional planning should align with material availability (stock size) and setup constraints (tool reach, machine envelope). Engineering drawings should clearly define:

- Critical Tolerances: Standard ±0.05 mm; tighter tolerances ±0.01–0.02 mm with cost tradeoffs.

- Flatness & Parallelism: Particularly for mating surfaces and assembled parts.

- Edge Breaks & Radii: Avoid sharp internal corners to reduce machining time.

A tighter tolerance requirement may double the cost and setup complexity for small batch runs.

Installation-Ready Parts: Threads, Inserts, and Assembly Prep

For parts destined for functional assembly, installation features must be carefully integrated:

- Threaded Holes: Tapped during machining or post-processed.

- Metal Inserts: Heat-set or press-fit for plastic parts.

- Countersinks / Counterbores: For flush mounting of screws.

- Alignment Features: Dowels, slots, or interlocking tabs.

These features add time and cost but are essential for ensuring downstream compatibility and reducing final assembly errors.

Cost Drivers and Optimization in Low Volume Production

CNC machining cost per part decreases with quantity, but the initial setup and programming remain constant. Key cost elements include:

- CAM programming time

- Toolpath verification

- Workholding setup (especially for odd geometries)

- Machining cycle time

- Secondary processing (deburring, tapping, anodizing)

| Quantity | Avg. Cost per Part (Aluminum) | Notes |

| 1–10 | $80–$200 | Prototype pricing |

| 11–100 | $25–$60 | Fixture cost amortized |

| 101–500 | $10–$30 | Optimal cost-performance zone |

| 500–1000 | $5–$20 | Semi-automated setups possible |

Design optimization—like avoiding thin walls, deep pockets, or unnecessary tight fits—can reduce cost by up to 40% in small batches.

Design Guidelines for Low Volume CNC Parts

Designing for small batch runs requires different priorities than for high-volume production:

- Use standard stock sizes to reduce lead time.

- Avoid thin walls <1.0 mm unless functionally necessary.

- Ensure tool accessibility to internal features.

- Avoid sharp inside corners—prefer fillets with radius >1.0 mm.

- Limit part reorientation to reduce setup time.

- Use threaded inserts instead of machining fine threads in plastic.

Good part design not only improves manufacturability but also ensures repeatability across 50, 200, or 1000 pieces.

Comparison Table: CNC vs 3D Printing vs Molding in Low Volume

| Process | Units | Setup Cost | Lead Time | Surface Finish | Suitable Materials |

| CNC Machining | 1–1000 | Medium | 3–10 days | Excellent | Metals, Engineering Plastics |

| 3D Printing (SLS/FDM) | 1–100 | Low | 1–5 days | Moderate | Plastics, Resins |

| Injection Molding | 500+ | High | 2–5 weeks | Excellent | Commodity Plastics |

| Vacuum Casting | 10–100 | Medium | 7–14 days | Good | PU, Silicone |

CNC is the most reliable method for functional, tight-tolerance, and production-grade materials in low volume runs.

Why Choose JeekRapid for Small Batch CNC Projects

JeekRapid offers precision low volume CNC machining with no minimum order quantity. Whether for 1 prototype or 800 functional parts, JeekRapid supports engineers through:

- In-house machining of aluminum, steel, and plastics

- Rapid programming and setup

- Multi-process finishing (anodizing, powder coating, laser marking)

- Global delivery with consistent lead time

All components are inspected against 2D drawings and 3D CAD to ensure complete spec compliance.

FAQ

- What is considered low volume machining?

Typically between 1 and 1000 parts, depending on complexity and part type. - What is the lead time for 100 machined parts?

Generally 5–10 business days depending on material and post-processing. - Can I order threaded aluminum parts in small batches?

Yes, CNC machining handles threaded holes, helicoils, and inserts. - How does JeekRapid price low volume orders?

Based on programming/setup time, machining hours, and part geometry. - Do you offer finishing for small batches?

Yes—anodizing, bead blasting, black oxide, and more. - What’s the tolerance for low volume CNC parts?

Standard ±0.05 mm; tighter upon request. - Is there an MOQ?

No, JeekRapid accepts orders from a single piece. - Can you machine stainless steel in low quantities?

Yes, 304, 316, and 17-4PH are all supported. - Do you provide material certifications?

Yes, on request—mill certs or COC available. - How do I get a quote?

Upload your drawing and specs at JeekRapid.com to receive a fast response.