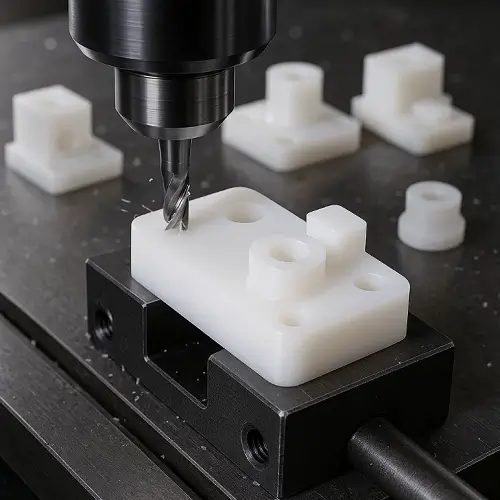

Among engineering plastics, Delrin (Polyoxymethylene, POM) and Nylon (Polyamide, PA) are often compared in CNC machining projects. Both plastics combine durability with machinability and are widely used for gears, bushings, housings, and small-batch prototypes. Engineers evaluating Delrin vs Nylon CNC machining typically want to know which plastic performs better in terms of tolerances, wear resistance, or overall cost.

This article examines Delrin and Nylon in detail, covering material properties, machining performance, advantages and disadvantages, and applications in different industries. Special attention is given to CNC precision, cost factors, and practical use cases.

What Is Delrin?

Delrin, the trade name for Polyoxymethylene (POM), was introduced by DuPont in the 1960s. The material was designed as a replacement for metals in precision parts, offering high stiffness, strength, and dimensional stability while remaining easy to machine.

Material Properties: Delrin provides tensile strength around 60–70 MPa, density of 1.41 g/cm³, and a low friction coefficient in the range of 0.2–0.35. Moisture absorption is below 0.2%, giving Delrin excellent dimensional stability even in environments with changing humidity.

CNC Machining Behavior: Delrin cuts smoothly and produces stable surfaces without warpage. The plastic reliably holds tolerances of ±0.01 mm, making Delrin suitable for gears, rollers, and high-precision bushings. Surfaces are typically glossy after machining, reducing the need for post-processing and lowering overall cost.

Applications: Delrin appears frequently in automotive fuel system parts, seat adjuster gears, conveyor rollers, electronic connectors, and FDA-compliant medical fixtures. The balance of machining precision and durability makes Delrin a practical choice for tight-tolerance CNC parts.

What Is Nylon?

Nylon, or Polyamide (PA), was developed in the 1930s as a synthetic fiber and later became one of the most common engineering plastics. Nylon is valued for toughness, flexibility, and resistance to wear, and it is produced in several grades such as Nylon 6, Nylon 66, and fiber-reinforced blends.

Material Properties: Nylon provides tensile strength of 70–80 MPa when dry, but strength can drop to about 45 MPa when the material absorbs moisture. Elongation at break often exceeds 100%, showing high toughness and impact resistance. Moisture absorption ranges from 1.5–2.0%, which strongly influences dimensional accuracy.

CNC Machining Behavior: Nylon is more difficult to machine than Delrin. The plastic absorbs moisture and may deform under cutting heat. Achieving tolerances of ±0.01 mm is possible, but requires sharp tooling, optimized cutting parameters, and stable environmental conditions. Surfaces are often rougher than those of Delrin parts, and additional finishing may be required.

Applications: Nylon is widely used for pulleys, bushings, bearings, fan blades, automotive housings, and consumer product casings. Lower cost and availability make Nylon attractive for high-volume production. In many applications where impact resistance and toughness are more important than dimensional stability, engineers prefer Nylon.

Delrin vs Nylon: Properties and Characteristics

-

Strength and Rigidity: Delrin provides higher stiffness and excellent dimensional accuracy, while Nylon offers greater toughness and higher impact resistance.

-

Moisture Resistance: Delrin absorbs minimal moisture and maintains tolerance; Nylon absorbs significantly more, which reduces strength and changes part dimensions.

-

Wear and Friction: Both materials resist wear, but Delrin has a lower friction coefficient, which makes it a better option for self-lubricating gears and sliding parts.

-

Chemical Resistance: Delrin resists fuels, oils, and solvents; Nylon shows good resistance to oils and alkalis but degrades in acidic environments.

-

Thermal Performance: Both operate up to ~120 °C, but Delrin holds dimensions more reliably under temperature shifts.

Delrin vs Nylon: Advantages and Disadvantages

Advantages of Delrin

-

High stiffness and stable strength

-

Consistent CNC machining precision

-

Low friction and excellent wear performance

-

Minimal need for secondary finishing

Disadvantages of Delrin

-

Higher material cost compared with Nylon

-

Limited long-term resistance at elevated temperatures

Advantages of Nylon

-

Exceptional toughness and impact resistance

-

Good wear behavior, especially in reinforced grades

-

Lower cost and broad availability

-

Flexibility for consumer and automotive components

Disadvantages of Nylon

-

High moisture absorption leading to dimensional instability

-

More difficult to machine smoothly

-

Requires tighter process control to hold tolerances

Delrin vs Nylon: Performance and CNC Machinability

CNC Tolerances: Delrin holds ±0.01 mm tolerances reliably, making it suitable for precision gears and rollers. Nylon can reach similar tolerances, but strict machining controls are required.

Surface Finish: Delrin generally produces smooth and glossy surfaces directly off the machine. Nylon tends to yield rougher finishes and may require polishing or other secondary operations.

Dimensional Stability: Delrin resists swelling and warping, while Nylon swells under moisture and may lose accuracy.

Wear Resistance: Both resist wear, but Delrin maintains performance longer in dry-running or high-precision assemblies.

Delrin vs Nylon: Key Differences

| Property | Delrin (POM) | Nylon (PA6/PA66) |

|---|---|---|

| Density (g/cm³) | 1.41 | 1.14 |

| Tensile Strength (MPa) | ~69 | ~75 (dry) / ~45 (wet) |

| Elongation at Break % | ~40 | ~100 |

| Water Absorption % | <0.2 | 1.5–2.0 |

| Friction Coefficient | 0.2–0.35 | 0.25–0.40 |

| CNC Tolerance | ±0.01 mm (stable) | ±0.01 mm (controlled) |

Delrin is chosen when accuracy, stability, and smooth finishes are essential. Nylon is selected for applications demanding toughness and cost efficiency.

Delrin vs Nylon: Applications Across Industries

-

Automotive: Delrin appears in fuel system gears and seat adjusters; Nylon is used for fan blades and engine covers.

-

Mechanical Equipment: Delrin serves in precision gears and cams; Nylon is used for pulleys, bushings, and wear rings.

-

Electrical: Delrin forms connectors and switch housings; Nylon is common in cable insulation and casings.

-

Medical Devices: Delrin meets FDA compliance for device components; Nylon is found in lower-cost healthcare products.

-

Prototyping: Delrin ensures reliable tolerances in low-volume CNC machining; Nylon reduces cost for larger prototype runs.

Delrin vs Nylon: How to Choose the Right Material

Selection depends on project requirements:

-

Choose Delrin for gears, bushings, or housings where tolerance stability and precision are critical.

-

Choose Nylon for high-impact parts or large production runs where cost efficiency matters more than dimensional accuracy.

-

In prototyping, Delrin reduces rework by holding tolerances; in large production runs, Nylon helps keep overall material cost under control.

- If you have any processing needs for Delrin and nylon materials, you can click here to get a quote and we will contact you within 24 hours.

FAQs — Delrin vs Nylon CNC Machining

Is Delrin stronger than Nylon?

Delrin is stiffer and dimensionally stable, while Nylon is tougher and resists impact better.

Which is easier to machine?

Delrin machines smoothly with consistent tolerances. Nylon requires sharp tools and tighter controls to avoid warping.

Does Nylon absorb water during CNC machining?

Yes. Nylon absorbs 1.5–2.0% water, which affects strength and dimensions.

Is Delrin more expensive than Nylon?

Yes. Delrin vs Nylon cost comparisons show Delrin generally costs more per unit.

Which material is better for gears or bushings?

Delrin is suitable for precision gears; Nylon works well for impact-resistant bushings and pulleys.

Is Delrin FDA compliant?

Certain grades of Delrin meet FDA standards, making the material suitable for medical device applications.