Development:Turning: Originated from ancient pottery wheels and woodworking lathes, turning evolved into a metal processing technique during the Industrial Revolution, laying the foundation for modern turning technology. By the 19th century, as lathes were gradually improved, turning became capable of stably processing cylindrical, conical workpieces and threads. It became one of the most fundamental processes in mechanical manufacturing.

Milling: Developed in the early 19th century by American engineer Eli Whitney and others, who designed the first mechanically driven milling machine, marking the transition from manual to mechanized milling. By the mid-19th century, changes in milling machine structure (such as the emergence of universal milling machines) enabled the processing of surfaces, grooves, and other complex shapes. In the 20th century, the application of CNC technology further expanded milling’s capability in multi-axis linkage machining.

What is CNC Turning?

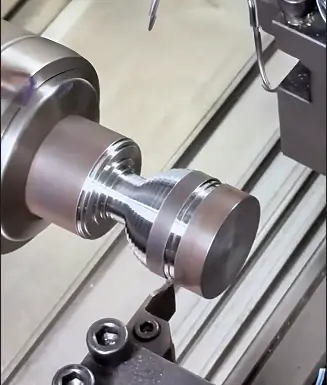

CNC turning is a high-precision, automated machining technique in which computer programs control the machine tool, enabling rotating workpieces to interact with fixed cutting tools to produce cylindrical, conical, or other rotationally symmetric parts.

Working Principle of CNC Turning

Workpiece clamping: The workpiece is fixed on a chuck or between centers, rotated at high speed by the spindle.

Tool movement: The turning tool (single-point cutting tool) moves along the X-axis (radial) or Z-axis (axial) based on the programmed path to gradually remove material.

CNC system: The CNC controller (such as Fanuc or Siemens) executes G-code commands to precisely control feed rate, cutting depth, and spindle speed, ensuring machining accuracy.

Core Equipment of CNC Turning

CNC lathes: standard type, slant bed, dual-spindle, etc.

Turret: holds multiple tools for automatic tool changing to improve efficiency.

Bar feeder: enables continuous machining of long bar-stock parts (such as shafts).

Sub-spindle: allows automatic flipping of the workpiece to complete double-sided machining (e.g., back drilling).

Typical CNC Milling Operations

| Operation Type | Function | Application Example |

|---|---|---|

| External Turning | Cutting the outer diameter of the workpiece | Shafts, rods |

| Facing | Smoothing the end face of the workpiece | Flanges, disc parts |

| Boring | Enlarging or finishing internal holes | Sleeves, housings |

| Thread Turning | Cutting internal or external threads | Bolts, nuts |

| Grooving / Parting | Machining annular grooves or parting off | Sealing grooves, finished part cut-off |

| Knurling | Impressing texture on the surface | Handles, adjustment knobs |

Advantages of CNC Turning

High precision: tolerances up to ±0.01mm, surface roughness Ra 0.8µm

High efficiency: automated production, suitable for batch processing

Complex shapes: capable of machining tapers, arcs, threads

Wide material range: suitable for metals (aluminum, steel, titanium), plastics, and even composites

What is CNC Milling?

CNC milling is a machining process in which a rotating multi-edge cutting tool removes material from a stationary workpiece. It is suitable for manufacturing complex geometries such as surfaces, contours, slots, and holes.

Working Principle of CNC Milling

Tool rotation: The milling cutter (e.g., end mill, face mill) is driven by the spindle to rotate at high speed.

Workpiece fixation: The workpiece is clamped onto the worktable, which moves along the X/Y/Z axes (or the tool moves).

Multi-axis linkage: 3-axis (basic), 4-axis (rotary table), 5-axis (tilting tool) enables complex machining.

Core Equipment of CNC Milling

Vertical Machining Center (VMC): vertical spindle, suitable for flat surface machining

Horizontal Machining Center (HMC): horizontal spindle, suitable for deep cavity machining

5-axis machining center: capable of producing freeform surfaces like impellers, aerospace parts

Typical CNC Milling Operations

| Operation Type | Function | Application Example |

|---|---|---|

| Face Milling | Machining flat surfaces | Machined panels |

| Contour Milling | Cutting external profiles | Mold cavities |

| Cavity Milling | Slotting or machining recessed features | Housings, enclosures |

| Drilling / Tapping | Machining holes or threads | Flange holes, threaded holes |

| 3D Surface Milling | Finishing complex curved surfaces | Automotive molds, sculptures |

Advantages of CNC Milling

High flexibility: capable of machining prismatic and asymmetric parts

Complex geometries: supports multi-axis linkage, enables 3D surface machining

High precision: micron-level tolerance and excellent surface finish

Material diversity: compatible with metals, plastics, wood, and composites

Advanced Applications of 5-Axis Milling

By tilting the tool or rotating the table, it reduces the need for multiple setups.

Typical applications: aerospace engine blades, medical instruments, automotive molds.

Comparison of Turning and Milling: Advantages and Disadvantages

Characteristic | Turning | Milling Advantages | High-efficiency machining of rotational parts (e.g., shafts, holes) | Capable of machining complex shapes (flat surfaces, 3D contours) Superior surface finish | High flexibility, supports multi-axis linkage Suitable for mass production of simple parts | Suitable for small-batch diverse parts Disadvantages | Limited to rotational parts | High equipment cost (e.g., 5-axis mills) Limited capability for complex shapes | Surface finish not as smooth as turning

Material Suitability:

Suitable materials for turning: aluminum, copper, low carbon steel, stainless steel—metals with good ductility. These allow for controlled continuous cutting and prevent excessive tool wear.

Suitable materials for milling: hard materials such as titanium alloys, hardened steel, and composites. Interrupted cutting helps with heat dissipation, and multi-edge tools share the cutting load.

Simple rotational parts or parts requiring high-precision cylindrical features are best suited for turning. For complex geometries and multi-face machining, milling is preferable. In modern machining, both methods are complementary.

Core Differences and Application Choices Between CNC Turning and CNC Milling

Core Differences:

Motion mode:

Turning → Workpiece rotates, tool moves (for rotational parts)

Milling → Tool rotates, workpiece moves (for complex shapes)

Machining object:

Turning: shafts, discs, threads, and other symmetric parts

Milling: flat surfaces, slots, 3D contours, and other asymmetric parts

Precision and Efficiency:

Turning is ideal for high-precision, high-volume rotational components

Milling is better for parts with multiple features and complex geometry

How to Choose?

Choose turning: for cylindrical/conical parts (e.g., screws, bearing sleeves)

Choose milling: for multi-featured parts (e.g., molds, housings)

Choose mill-turn (combined): for parts requiring both (e.g., threaded irregular shapes)

In modern manufacturing, mill-turn technology combines the strengths of both processes, completing complex part machining in a single setup. Turning is ideal for rotational parts, milling for complex shapes, and mill-turn for comprehensive needs. By leveraging both techniques, manufacturers can achieve high precision and efficiency.

We offer a full range of CNC turning and milling services, ready to support your production with high-quality parts. Once we receive your design drawings, we start production immediately to meet your speed and requirements. If you’re ready, feel free to contact Jeek for a quote, and we will provide you with dedicated one-on-one service!