Early prototypes often check only form and fit—proportions, feedback, or concept approval. But when a product faces mechanical validation, mere appearance won’t suffice. At this stage, prototypes must endure real-world forces: stress, heat, torque, and precise mating tolerances.

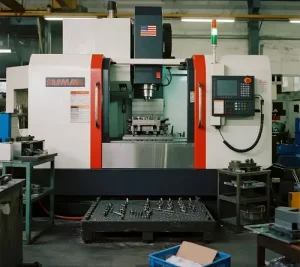

A tiny misalignment or surface flaw can cause a test failure. To replicate production-level behavior quickly—without the time or cost of tooling—CNC machining is one of the few methods that delivers both speed and true-to-life function.

What Makes a Prototype Truly Functional?

A functional prototype goes beyond geometry. It means:

Dimensions are held tightly to spec—consistently and reliably

Materials behave like production parts, not just visually similar

Surfaces can be machined, tapped, fastened, or sealed as needed

The part performs in real field conditions, not just on the bench

For example, a UAV project once tested an SLA-printed enclosure that flexed and loosened during flight vibrations. Switching to a machined ABS-aluminum hybrid solved the issue, enabling real-world bracket validation.

Why CNC Outperforms Other Prototyping Methods

Speed matters, but material behavior is critical. Many choose 3D printing for speed, yet printed plastics rarely match the strength, friction, or thermal properties of POM or aluminum. Testing screw inserts, bearings, or multi-part assemblies exposes these limits.

CNC machining offers:

Tight, repeatable tolerances suited for mechanical fits like shafts and bearings

Real materials: metals, industrial plastics, and thermally stable blends

Small runs from 1 to 50 units that survive rigorous field testing

One medical client initially used printed parts that failed stress at joint seams. We delivered Delrin prototypes that passed autoclave simulation within days—avoiding misdiagnosis of design flaws and saving costly delays.

Key Use Cases for Functional CNC Prototypes

When precision, durability, and test results matter, CNC prototypes lead. Typical scenarios include:

-

Assembly Validation: Testing interaction and fit of multiple mechanical parts

-

Thermal Testing: Using metal components to measure heat dissipation or retention

-

Strength & Pressure Validation: Assessing torque, sealing force, and vibration resistance

-

Pilot Runs: Delivering low-volume batches to early users or regulators

-

Compliance Checks: Providing physical samples for FDA, CE, or UL certifications

These use cases don’t tolerate guesswork—functional accuracy is essential.+

Material Choices That Reflect Real Conditions

The accuracy of design validation depends on material behavior. Prototypes that melt, crack, or distort under normal use provide no real insight.

Common materials we machine include:

-

6061-T6 Aluminum: Lightweight, rigid housings and brackets for aerospace or consumer electronics

-

Stainless Steel 304/316: Corrosion-resistant parts for medical or marine environments

-

POM (Delrin): Moving parts like gears, sliders, and hinges with low friction

-

PEEK: High-temperature, chemical-resistant components used in automotive and medical devices

Choosing the right material is critical—wrong choices can undermine a sound design.

When CNC is the Right Call

Recently, a robotics team struggled with a resin-printed arm joint that failed under minor torque. The design was solid, but the material lacked strength and thread retention. We machined the part in 7075 aluminum, which passed load tests and maintained alignment over multiple stress cycles.

That’s when CNC is essential—not for looks, but for function.

Discovering limits early saves time and money. CNC lets you simulate reality without waiting for molds, dies, or external vendors.

Conclusion: Test with Confidence, Not Assumptions

Functional prototyping isn’t about perfection—it’s about meaningful failure or confirming durability.

CNC machining empowers design teams to learn before commitment. Whether finalizing tolerances, validating structure, or preparing pilot runs, precision prototypes can mean the difference between confidence and costly redesigns.

At JeekRapid, we support teams who care about how things work—not just how they look.

Ready to test your design under real conditions?

Send us your CAD files, and we’ll machine what truly matters.