In modern manufacturing, ceramic materials have become widely adopted across various industries due to their high temperature resistance, corrosion resistance, and exceptional hardness. With the advancement of CNC machining in the 21st century, ceramics are now being precisely machined, opening new possibilities in electronics, medical, aerospace, and other sectors. However, the brittle nature and machining difficulty of ceramics impose higher demands on manufacturing processes. This article delves into the core processes, key parameters, and technical challenges of ceramic CNC machining, while sharing Jeek’s advanced expertise in this field.

What is Ceramic CNC Machining?

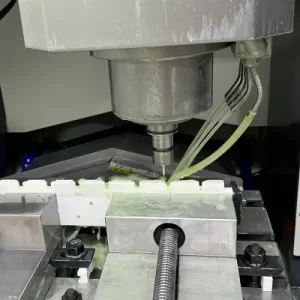

Ceramic CNC machining involves using computer numerical control machines equipped with specialized tooling to precisely cut and shape ceramic materials. Due to ceramics’ high hardness and brittleness, traditional metal machining methods are often unsuitable. Ceramic parts are usually rough-machined in their green (unsintered) state before undergoing high-temperature sintering to improve hardness and density, followed by fine diamond tooling for precision cutting to achieve tight dimensional tolerances. CNC systems ensure strict control over tool paths and cutting parameters, enabling complex shapes and excellent surface finishes.

Why Use Ceramics in CNC Projects?

Ceramics are widely used in extreme environments due to their heat resistance, corrosion resistance, lightweight nature, and excellent electrical insulation. They help reduce equipment failure rates and maintenance costs. For example, ceramics serve as insulators and substrates in the semiconductor industry, biocompatible implants in medical applications, and high-temperature resistant engine components in aerospace. CNC machining enables the creation of complex ceramic parts that meet modern manufacturing’s stringent demands for both high performance and precision.

Key Parameters in Ceramic CNC Machining

Machining ceramics requires precise control over cutting parameters, including:

Cutting Speed: Typically maintained between 10-50 meters per minute to avoid excessive heat that can cause cracks.

Feed Rate: Extremely low feed speeds (millimeters per minute) to ensure smooth cutting.

Cutting Depth and Width: Micron-level material removal to prevent excessive cutting forces that could cause material chipping.

Tool Material: Diamond or cubic boron nitride (CBN) tools are used for their high hardness, improving efficiency and tool life.

Cooling Method: Appropriate use of coolant reduces heat buildup and thermal stress cracks.

Spindle Speed: Lower speeds minimize vibrations and reduce tool chipping risk.

Note: Parameters must be adjusted flexibly depending on the specific ceramic material.

Diverse Processes in Ceramic CNC Machining

Multiple specialized machining methods address the high hardness and brittleness of ceramics:

CNC Milling: The most common method, using diamond-coated or carbide tools to effectively remove ceramic material and achieve complex geometries and fine details.

Surface Grinding: Widely used for parts requiring high surface finish, employing diamond grinding wheels to produce components capable of withstanding high stress, such as aerospace parts.

Laser Cutting: A non-contact, high-precision process ideal for cutting thin ceramic sheets and complex contours, avoiding cracks caused by mechanical tools.

Core Drilling: Uses hollow diamond drill bits to precisely core holes, minimizing stress concentration and preventing cracking.

ID Slicing: Applied to ultra-precise ceramic parts like silicon wafers, ensuring smooth cut surfaces with minimal material loss.

Additionally, diamond grinding is critical for achieving high precision and excellent surface quality in ceramic parts, improving tool life and reducing thermal damage. Wafer dicing focuses on precision cutting of thin materials for electronics and silicon wafers.

During forming, hot pressing and isostatic pressing play vital roles. Hot pressing densifies ceramic powders under high temperature and pressure to enhance strength and wear resistance. Isostatic pressing applies uniform pressure, ensuring consistent material structure, especially for complex shapes and high-strength ceramic parts.

How Jeek Performs Ceramic CNC Machining

Jeek boasts extensive experience in ceramic machining, combining high-precision CNC equipment with a professional process team. We offer one-stop services from material selection and process design to precision machining. Using advanced diamond tooling and multi-axis technology, we carefully plan tool paths and control cutting parameters to minimize cracking and chipping risks.

Jeek continually optimizes processes through data feedback to ensure dimensional stability and superior surface quality. Whether machining green blanks before sintering or performing fine machining after sintering, we provide comprehensive solutions to meet the rigorous demands of various industries.

Common Applications and Use Cases

Semiconductor manufacturing: high-temperature insulating components and equipment supports.

Medical devices: dental and orthopedic implants combining biocompatibility with mechanical strength.

Electronics: insulating and supporting structures for high-frequency components.

Aerospace: engine parts and wear-resistant protective coatings.Industrial machinery: wear-resistant liners and durable sealing components.

These applications highlight ceramics’ irreplaceable role in high-performance environments.

Common Challenges in CNC Machining of Ceramics

Typical challenges include:

Rapid tool wear, increasing replacement frequency and cost.

Material chipping and cracking, mainly caused by improper cutting parameters.

Machining accuracy fluctuations due to ceramic brittleness and machine vibration.

Micro-cracks induced by thermal stress, especially if cooling is inadequate.

Insufficient machine rigidity, leading to degraded surface quality.

Jeek mitigates these issues through strict equipment maintenance, precise parameter setting, and continuous process optimization, ensuring high-quality product delivery.

Conclusion:

Ceramic CNC machining is not a task accomplished overnight. It demands patience, experience, and precise technology. When done correctly, it produces durable, lightweight, and high-performance parts that outperform traditional materials.

If your project requires ceramic components or you’d like to determine whether ceramics are the right material for your application, please feel free to contact us. We can also provide samples in advance for your evaluation, and once you’re satisfied, we’d be glad to discuss further collaboration.Get a quote today to explore what Jeek can do for your project.