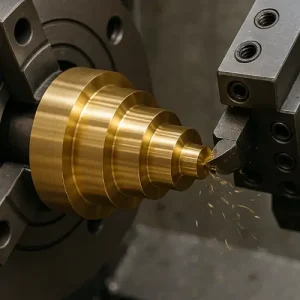

CNC Material Selection and Cost Trade-offs

Material choice is one of those decisions in CNC machining that looks simple on paper, then quietly controls everything that follows — cycle time, tool life, scrap rate, even whether the schedule survives first article.

Anyone who has run real projects has seen the same drawing produce very different numbers on the quote sheet, just …