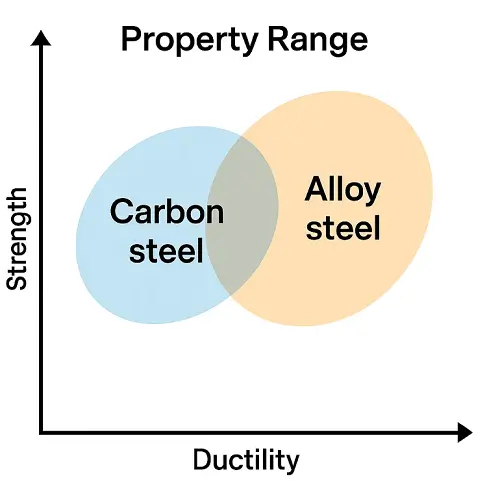

Steel is not a single material but a family of alloys built around iron and carbon. The performance of steel changes dramatically with adjustments to carbon percentage and the addition of other alloying elements. For engineers, two categories appear most frequently in design and production: carbon steel and alloy steel.

Questions like “what is carbon steel,” “what is alloy steel in chemistry,” or “alloy steel vs carbon steel which is stronger” reflect how often these materials are compared. The choice between them affects mechanical properties, processing requirements, and cost efficiency in industries ranging from construction to aerospace.

What Is Carbon Steel?

Carbon steel is an iron–carbon alloy in which carbon is the main alloying element. The carbon content generally lies between 0.02% and 1.5%, and only small amounts of other elements such as manganese or silicon are present. Because it lacks significant chromium, nickel, or molybdenum, carbon steel’s properties are dominated by carbon content and heat treatment.

Categories of carbon steel:

Low carbon steel (<0.25% C)

Also called mild steel, valued for ductility and weldability. Common grades include AISI 1008 and 1018. Tensile strength is typically 400–550 MPa, hardness around 120–160 HB, making it suitable for pipelines, sheet metal, and automotive body parts.

Medium carbon steel (0.25–0.6% C)

Offers balanced strength and toughness. AISI 1045 is a well-known example, reaching 600–800 MPa tensile strength after heat treatment. Used in gears, shafts, and machine parts.

High carbon steel (0.6–1.5% C)

Known for high hardness and wear resistance. Grades like AISI 1095 can achieve >60 HRC hardness when quenched, but ductility drops sharply. Common in knives, springs, and cutting tools.

carbon steels are prone to rust. Without protective coatings, exposure to moisture leads to red oxide formation, which explains why searches like “does carbon steel rust” are frequent. In humid or marine conditions, galvanizing or painting is essential.

What Is Alloy Steel?

Alloy steel refers to steels containing deliberate additions of alloying elements such as chromium, molybdenum, nickel, vanadium, and manganese. These elements, typically in the 1–10% range, significantly influence mechanical performance.

Types of alloy steel

Low-alloy steels (≤5% alloying elements)

Examples include 4140 (Cr-Mo steel) and 4340 (Ni-Cr-Mo steel). These grades achieve 800–1000 MPa tensile strength and excellent fatigue resistance, making them popular for automotive axles, gears, and pressure vessels.

High-alloy steels (>5% alloying elements)

Includes stainless steels with ≥10.5% chromium and tool steels with high tungsten or vanadium. Stainless grades form a passive oxide layer, providing corrosion resistance. Tool steels like H13 or D2 achieve extreme hardness for cutting and forming dies.

Typical properties

Tensile strength can exceed 1200 MPa in quenched and tempered condition.

Hardenability is greater than carbon steels, meaning large cross-sections can be hardened uniformly.

Corrosion resistance varies: chromium- or nickel-bearing alloys resist rust far better than plain carbon steel.

Fatigue resistance is superior, a reason alloy steel vs carbon steel debates often arise in aerospace and energy sectors.

3Differences Between Carbon Steel and Alloy Steel

Extended Comparison Table

| Category | Composition | Tensile Strength | Hardness (HB/HRC) | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Low Carbon Steel (Mild Steel) | <0.25% C, minor Mn/Si | 400–550 MPa | 120–160 HB | AISI 1008, 1018 | Pipelines, automotive body panels, structural beams |

| Medium Carbon Steel | 0.25–0.6% C | 600–800 MPa | 170–220 HB (annealed), up to 50 HRC (quenched) | AISI 1040, 1045 | Shafts, gears, axles, machine components |

| High Carbon Steel | 0.6–1.5% C | 800–1000+ MPa | 200 HB (annealed), up to 60+ HRC (quenched) | AISI 1080, 1095 | Cutting tools, springs, knives, high-strength wires |

| Low-Alloy Steel | ≤5% alloying elements (Cr, Mo, Ni, V) | 800–1100 MPa (heat-treated) | 200–300 HB, up to 55 HRC | AISI 4130, 4140, 4340 | Automotive gears, pressure vessels, oil & gas pipelines |

| High-Alloy Steel | >5% alloying elements, e.g., Cr ≥10.5% (stainless) | 900–1500 MPa depending on type | 200–350 HB, up to 65 HRC (tool steels) | Stainless 304/316, H13, D2 | Aerospace parts, turbine components, hot-work dies, corrosion-resistant structures |

This expanded comparison makes clear why carbon steels dominate cost-sensitive structural applications, while alloy steels are reserved for high-performance parts.

Applications of Carbon Steel and Alloy Steel

Carbon Steel Applications

Construction: beams, pipelines, rebar, general structural parts.

Automotive: body panels, chassis, fasteners.

Tools: knives, hand tools, cutting blades.

Pressure vessels: mild steel grades for tanks and boilers.

Alloy Steel Applications

Aerospace: landing gear, shafts, turbine components.

Automotive: alloy steel gears, axles, and crankshafts.

Oil & Gas: alloy steel pipes, valves, and drill collars.

Tooling: chrome–vanadium wrenches, dies, and molds.

Carbon Steel vs Alloy Steel in CNC Machining

In CNC machining, machinability and tool wear are major concerns.

Carbon Steel

mild steel (AISI 1018) machines easily with high material removal rates. Medium carbon steels like AISI 1045 require more rigid setups and careful cooling. High carbon steels, especially hardened, are challenging—typically machined in annealed state and heat treated later.

Alloy Steel

generally harder to machine due to higher strength. 4140 and 4340 require coated carbide tools, optimized feeds, and rigid setups. Tool wear is significant, but the resulting parts offer higher fatigue resistance and dimensional stability.

For CNC prototyping, carbon steels are common due to cost and ease of machining. In production environments where part life is critical, alloy steels are preferred.

Alternatives to Carbon and Alloy Steels

Engineers sometimes evaluate other materials depending on weight, corrosion, or cost requirements:

Stainless Steel: a high-alloy steel with ≥10.5% chromium, excellent for corrosion resistance.

Aluminum Alloys: lightweight, corrosion-resistant, used in automotive and aerospace.

Titanium Alloys: superior strength-to-weight, but expensive and difficult to machine.

Composites (carbon fiber): extremely high stiffness-to-weight, sometimes compared directly as “carbon steel vs carbon fiber.”

Conclusion

Carbon steel and alloy steel remain two of the most widely applied materials in modern industry. Carbon steels are valued for their affordability and ease of machining, while alloy steels are chosen for higher strength, toughness, and fatigue resistance. In CNC machining, carbon steels are often used for prototypes and general components, whereas alloy steels are specified when long-term durability is essential.

At JeekRapid, material processing is supported by internationally recognized quality systems, including ISO 9001 and ISO 13485 certifications. With more than 20 years of engineering experience and advanced CNC machining capabilities, JeekRapid manufactures precision parts in both carbon steel and alloy steel, from single prototypes to low-volume production.

If you are planning a project with carbon steel or alloy steel parts, you can upload your CAD files to request a free quotation. JeekRapid’s engineering team will provide feedback on material selection, tolerances, and cost efficiency before production.

References (text citation only):

-

ASM Handbook, Vol. 1: Properties and Selection: Irons, Steels, and High-Performance Alloys

-

ASTM International – Steel Standards for Carbon and Alloy Steels

-

SAE International – Steel Material Specifications

8. FAQ

Q1. Does carbon steel rust faster than alloy steel?

Yes. Without chromium or nickel, carbon steel forms rust rapidly in humid environments.

Q2. Which is stronger, iron or steel?

Steel is stronger; controlled carbon and alloying make it superior to pure iron.

Q3. Is stainless steel considered an alloy steel?

Yes, stainless steel is a high-alloy steel with ≥10.5% chromium.

Q4. What is the carbon percentage in steel?

It ranges from about 0.02% in mild steel to 1.5% in high-carbon steel.

Q5. Which is cheaper, carbon steel or alloy steel?

Carbon steel is generally cheaper, while alloy steel cost varies with element additions.

Q6. Is alloy steel suitable for welding?

Yes, but preheating and post-weld heat treatment may be required to avoid cracking.

Q7. Can alloy steel and carbon steel be used together?

Yes. Many assemblies combine mild carbon steel structures with alloy steel shafts or fasteners for performance.