Aluminum has become one of the most widely applied materials in modern manufacturing. Lightweight structure, corrosion resistance, and excellent machinability make aluminum suitable for industries ranging from aerospace to medical technology. A natural oxide film forms on untreated aluminum, but this film lacks uniform thickness and limited durability. Anodizing provides a controlled method to create thicker oxide layers with consistent properties. The process is widely used to extend product life, improve wear resistance, and enhance appearance. Engineers often ask practical questions such as how to anodize aluminum parts, which alloys are suitable, what film thickness is recommended, and whether anodizing remains cost-effective for CNC-machined components.

What is Anodizing Aluminum?

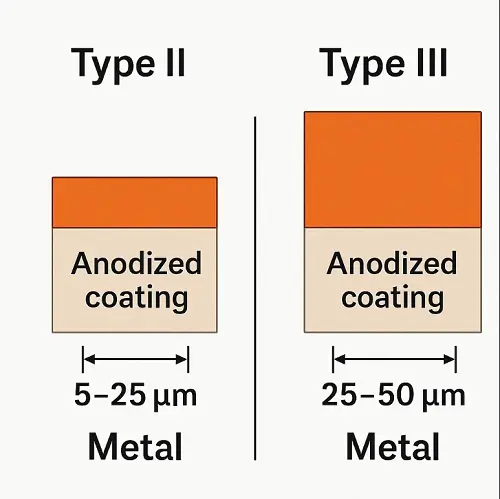

Anodizing aluminum is an electrochemical process that transforms the surface into aluminum oxide. During processing, the component becomes the anode in an electrolytic bath, and oxygen ions released from the electrolyte bond with the surface. The oxide layer is integral to the base metal, which makes it resistant to peeling or flaking. Standards such as MIL-A-8625 classify anodizing into categories, including Type II for decorative use and Type III for hard anodizing. Type II anodizing is common for consumer products and housings, while Type III is selected when parts require high wear resistance, such as aerospace and defense applications.

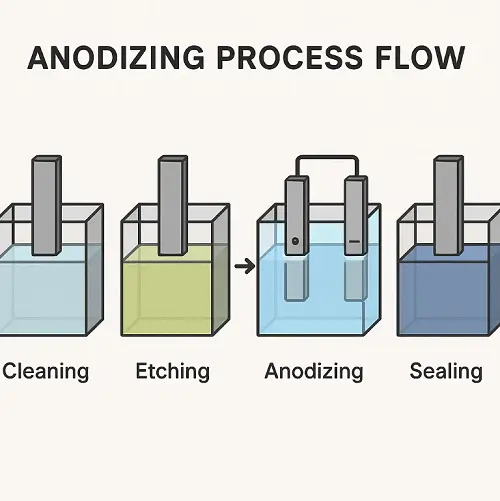

How to Anodize Aluminum Parts Step by Step

The anodizing sequence begins with surface preparation. Components are degreased, rinsed, and cleaned using acid treatment to remove contaminants. After preparation, the aluminum is immersed in an electrolytic bath, usually sulfuric acid. A direct current passes through the bath, with aluminum acting as the anode and lead or stainless steel as the cathode. Film thickness depends on the electrolyte composition, bath temperature, current density, and processing time. After the target thickness is achieved, parts are rinsed and sealed. Sealing is often performed with hot water or nickel acetate, which closes surface pores and improves corrosion resistance. Industrial anodizing ensures uniform results across large batches, which is critical for aerospace structures, automotive housings, and consumer electronics.

Can 6061 and 7075 Aluminum Be Anodized?

6061-T6 aluminum is considered the most versatile alloy for anodizing. The alloy responds consistently to both Type II and Type III processes, delivering stable film thickness, reliable coloring, and corrosion resistance. 7075 aluminum also accepts anodizing but produces darker oxide films with reduced corrosion resistance compared with 6061. For aerospace or defense applications, engineers frequently specify hard anodizing of 7075 to achieve dense protective films that extend service life. Alloy selection plays a decisive role in surface quality after anodizing, which means component performance depends not only on machining accuracy but also on material compatibility with the process.

What Thickness is Anodizing Aluminum?

Anodizing thickness varies by process. Type II anodizing produces oxide films in the 5–25 µm range, which is sufficient for consumer goods and housings where appearance and basic protection are priorities. Type III hard anodizing produces thicker layers in the 25–50 µm range, delivering superior wear resistance required in aerospace, defense, and heavy-duty applications.

| Anodizing Type | Typical Thickness | Application |

|---|---|---|

| Type II (decorative) | 5–25 µm | Consumer products, housings |

| Type III (hard) | 25–50 µm | Aerospace, defense, wear parts |

In electric vehicle battery enclosures, 6061-T6 aluminum is frequently selected because it balances machinability and corrosion resistance. Manufacturers often specify Type II anodizing with a film thickness of 15–20 µm. This range provides reliable protection against road salt and environmental exposure, while also maintaining dimensional accuracy for sealing interfaces. The anodized layer further reduces galvanic corrosion when the housing is joined with fasteners made from stainless steel or other dissimilar metals. Controlled thickness allows the battery housing to remain lightweight while protecting sensitive internal components.

Design consideration: anodizing changes surface roughness compared with as-machined aluminum. Engineers evaluate Ra values before deciding whether to apply anodizing, powder coating, or other finishing processes.

Why Anodize Aluminum Parts Instead of Other Coatings?

Anodizing delivers benefits beyond those of painting or plating. The oxide film integrates with the base material, creating a finish that does not peel under stress. Type II anodizing improves corrosion resistance in outdoor or marine environments, while Type III provides hardness comparable to hardened steel. Anodizing also enables dyeing, allowing engineers to achieve black, gold, red, or other finishes without losing dimensional control. Compared with powder coating, anodizing provides thinner, uniform oxide films that are well suited for tight-tolerance CNC components. Powder coating, on the other hand, produces thicker layers with stronger impact resistance, making it a better option for exterior architectural parts or large consumer products. Selection between anodizing and powder coating depends on whether dimensional accuracy or mechanical toughness is the primary requirement.

Is Anodizing Aluminum Expensive?

Anodizing costs vary depending on alloy, thickness, color, and order size. Prototype components often cost more per unit because setup and processing cannot be distributed. In contrast, small-to-medium batch production significantly reduces per-unit cost. Type II anodizing at 10–15 µm is generally less expensive than Type III at 40–50 µm, which requires longer processing times and higher energy input.

| Application | Quantity | Anodizing Type | Approximate Cost per Part* |

|---|---|---|---|

| Prototype housing | 1 | Type II, clear | $100–150 |

| Consumer electronics case | 100 | Type II, dyed | $15–30 |

| Aerospace structural bracket | 50 | Type III, hard | $40–70 |

*Costs vary depending on geometry, supplier, and finishing requirements.

Batch anodizing delivers strong value in CNC manufacturing because enhanced corrosion resistance and reduced maintenance often offset the initial finishing cost.

Can Anodized Aluminum Be Machined Afterward?

Post-machining of anodized parts is technically possible, but cutting tools remove or damage the oxide layer. Removing the layer reduces protection against corrosion and alters appearance. Best practice in manufacturing is to complete machining before anodizing, while also compensating tolerances during design to account for expected film growth.

What Colors Are Available for Aluminum Anodizing?

Anodizing allows both natural and dyed finishes. Clear anodizing preserves the metallic appearance, while dyes introduce colors such as black, gold, red, and blue. The ability to achieve consistent color depends on alloy composition and bath parameters. Alloys like 6061 produce uniform coloring, while alloys like 7075 may produce darker shades. Consumer electronics often use colored anodizing for housings, combining aesthetics with surface durability.

Applications of Anodized Aluminum

Anodized aluminum is widely used across aerospace, automotive, medical, and consumer industries. Aerospace applications include hard anodized brackets and housings that maintain performance under extreme environments. Automotive applications extend to trim, engine covers, and electric vehicle battery housings. Medical devices benefit from anodized housings that withstand sterilization cycles. Consumer electronics such as laptops and smartphones adopt anodized finishes to balance premium appearance with scratch resistance.

Conclusion and JeekRapid Services

Anodizing remains one of the most effective finishing processes for aluminum parts. The technique enhances corrosion resistance, surface hardness, and appearance while maintaining dimensional accuracy. JeekRapid offers CNC machining combined with anodizing services under ISO-certified processes, supporting Type II and Type III requirements. Customers benefit from fast lead times, competitive pricing, and engineering support for tolerance design and alloy selection. Upload CAD files to JeekRapid for a rapid quotation and integrate anodizing into production with confidence.

FAQ: Common Questions About Anodizing Aluminum

Q: Can 7075 aluminum be anodized for aerospace use?

Yes, 7075 aluminum can undergo hard anodizing. The oxide film is dense and provides wear resistance, which is essential in aerospace structural parts, although corrosion resistance remains lower than 6061.

Q: What thickness is typical for Type III hard anodizing?

Type III anodizing usually produces films of 25–50 µm. Aerospace brackets, defense housings, and industrial wear components commonly specify this range.

Q: Is anodizing aluminum expensive for low-volume CNC parts?

For prototypes, the cost per unit is higher because of setup overhead, but small batches achieve better economies of scale. Many manufacturers still choose anodizing because the long-term durability reduces lifecycle cost.

Q: What colors are available in anodized finishes?

Common finishes include clear, black, gold, red, and blue. Color stability depends on alloy selection and process parameters.

Q: How does anodizing compare with powder coating for aluminum parts?

Anodizing creates thin, controlled oxide films suitable for precision components, while powder coating produces thicker layers with greater impact resistance. Anodizing is better for CNC housings and parts with tight tolerances, while powder coating is often selected for larger, exterior components where thickness and impact strength are more important.