CNC prototyping is one of the most effective methods to create high-quality prototypes during product development. Unlike conceptual models made by 3D printing, CNC prototypes are fully functional parts manufactured from real engineering materials. Many companies rely on rapid CNC prototyping to shorten design cycles, evaluate mechanical properties, and prepare for pilot production runs before scaling up.

What Is CNC Prototyping?

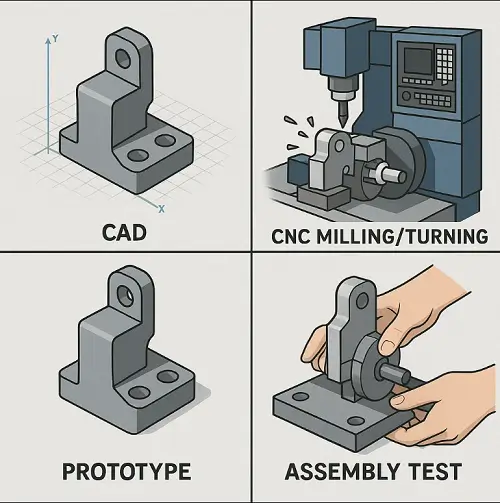

CNC prototyping refers to the use of CNC machining processes—such as milling, turning, drilling, and grinding—to create prototype parts directly from digital CAD models. By subtractive manufacturing, material is removed from a block to achieve the final geometry. The resulting prototypes replicate production parts in terms of accuracy, tolerance, and material behavior.

Core features of CNC prototyping include

High precision: tolerances down to ±0.01 mm

Material versatility: metals and plastics suitable for end-use

Repeatability: consistent parts across multiple iterations

Fast lead time: typically 2–7 days depending on complexity

Why CNC Prototyping Matters in Product Development

Design Verification

Prototypes allow designers to evaluate geometry, ergonomics, and aesthetics in a practical setting. For example, an aluminum bracket can be mounted in a vehicle to check clearances with wiring and fasteners. This validation step helps ensure potential alignment or tolerance issues are identified early.

Functional Testing

CNC prototypes provide the same strength and durability as production components. A stainless steel tool prototype can be sterilized multiple times without deformation, while an aerospace aluminum part can undergo fatigue and vibration tests. These trials deliver reliable data for final design approval.

Assembly Fit Check

Prototypes confirm compatibility with mating parts and fasteners. Threads, holes, and slots can be machined to exact specifications, ensuring smooth assembly. This is critical in sectors like hydraulics or automotive transmissions where a small misalignment could lead to leakage or malfunction.

Risk Reduction

By testing prototypes first, companies reduce the risk of discovering flaws after tooling investment. A design flaw corrected during prototyping costs far less than redesigning a hardened mold, saving both time and resources.

Bridge Production

CNC prototyping enables the production of low-volume batches before full-scale manufacturing. For instance, a robotics company can build 50 housings for pilot runs without waiting for injection molds, ensuring faster time-to-market.

Advantages of CNC Prototyping

High Dimensional Accuracy

CNC machining achieves tolerances as tight as ±0.01 mm. This level of accuracy ensures prototypes replicate production conditions, making them suitable for critical assemblies in aerospace, automotive, and medical devices.

Wide Material Compatibility

From aluminum and stainless steel to ABS, POM, and polycarbonate, CNC prototyping supports a broad range of engineering materials. Both metal and plastic CNC prototyping can be applied depending on the design goals, whether the part is structural or cosmetic.

Superior Surface Finishes

Prototypes can be finished with bead blasting, anodizing, polishing, or coating to match end-use requirements. An anodized aluminum housing can undergo corrosion testing, while a polished acrylic lens can simulate optical performance in final products.

Strong Mechanical Performance

Because prototypes are machined from solid engineering materials, they exhibit isotropic strength. This makes them reliable for functional testing, including load, wear, and fatigue assessments that mimic real-world performance.

Fast Iteration Cycles

CNC prototyping enables quick turnaround, often within days. This allows engineers to test, modify, and retest designs in short cycles, accelerating product development. In industries like consumer electronics, this speed is critical for staying ahead of market demand. Many CNC prototype services emphasize their ability to deliver parts within a week to support rapid design changes.

CNC Prototyping vs Other Methods

| Feature | CNC Prototyping | 3D Printing | Vacuum Casting | Injection Molding |

|---|---|---|---|---|

| Tolerance | ±0.01–0.05 mm | ±0.1–0.2 mm | ±0.1–0.2 mm | ±0.01 mm |

| Surface Finish | Smooth, machinable | Layered | Smooth | Excellent |

| Materials | Metals & plastics | Limited polymers | PU resins | Engineering plastics |

| Strength | Production-grade | Lower, anisotropic | Medium | Production-grade |

| Lead Time | 2–7 days | 1–3 days | 1–2 weeks | 3–5 weeks |

| Tooling Required | No | No | Silicone molds | Expensive steel molds |

This comparison demonstrates why CNC prototyping is favored when accuracy, durability, and real material performance are required.

Materials for CNC Prototyping

Aluminum (6061, 7075, 2024)

Lightweight, corrosion resistant, and highly machinable. 6061 is used for housings and general-purpose brackets. 7075 offers higher strength, often applied in aerospace and drones. 2024 excels in fatigue resistance, common in automotive suspension systems.

Stainless Steel (304, 316, 17-4 PH)

304 is versatile, 316 offers marine and medical resistance, while 17-4 PH provides both hardness and corrosion protection. Ideal for implants, valves, shafts, and surgical tools.

Brass

Easy to machine, conductive, and decorative. Suitable for electrical connectors, terminals, valve bodies, and polished fittings.

Titanium (Grade 2, Grade 5)

Grade 2 is corrosion resistant and used for chemical and biomedical parts. Grade 5 (Ti-6Al-4V) is stronger, chosen for aerospace structures, implants, and performance automotive prototypes.

ABS

Durable, cost-effective, often used for consumer product housings. Can be painted or plated to simulate injection-molded surfaces.

POM (Delrin)

Dimensional stability and low friction make it ideal for gears, bearings, and mechanical jigs.

Nylon (PA6, PA66)

Strong and flexible, suitable for bushings, gears, and clips. Tested in environments with humidity or vibration.

Acrylic (PMMA)

Transparent and polishable to optical clarity. Used for lenses, display windows, and covers.

Polycarbonate (PC)

Transparent but tougher than acrylic, impact resistant, suitable for safety shields and lighting components.

Comparative Material Properties Table

| Material | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Machinability | Typical Surface Finish | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 95 | Excellent | Anodizing, polishing | Housings, brackets |

| Aluminum 7075 | 540 | 120 | Moderate | Hard anodizing | Aerospace, drones |

| Stainless 316 | 550 | 315 | Moderate | Polishing, passivation | Medical, marine |

| Brass C360 | 350 | 100 | Excellent | Polished, plated | Connectors, valves |

| ABS Plastic | 45 | 85 | Easy | Painted, textured | Consumer housings |

| Acrylic (PMMA) | 70 | 95 | Fair | Polished clear | Optical lenses |

| Polycarbonate | 65 | 125 | Moderate | Polished, coated | Safety covers |

This comparison highlights the balance between strength, machinability, thermal resistance, and finishing options, helping engineers select the right material for their prototypes.

Applications of CNC Prototyping

Aerospace – aircraft brackets, housings, and engine prototype parts.

Automotive – prototype gears, housings, and dashboard elements.

Medical Devices – surgical tools, implants, and testing instruments.

Consumer Electronics – phone housings, enclosures, and accessories.

Industrial Equipment – fixtures, gauges, and small-batch mechanical parts.

As a global CNC prototype manufacturer, JeekRapid supports industries from aerospace to consumer electronics. With operations in China, JeekRapid provides efficient CNC prototyping solutions for clients worldwide.

Precision, Tolerances, and Surface Finishes

Tolerances

Standard CNC tolerance is ±0.05 mm, with ±0.01 mm achievable on advanced 5-axis machines. Thread profiles include ISO, UNC, UNF, and custom geometries, ensuring compatibility with production components.

Surface Finishes

As-machined (Ra 3.2 µm) – suitable for functional prototypes.

Bead blasting – matte surface.

Anodizing – corrosion resistance and aesthetics for aluminum.

Polishing & buffing – mirror finish for plastics like acrylic.

Powder coating – durable protection for mechanical parts.

Lead Time and Cost Factors

Lead Time

Simple prototypes: 2–3 days

Complex 5-axis parts: 5–7 days

Small-batch runs (50–200 pcs): 1–2 weeks

Cost Drivers

Material type – titanium and stainless steel are more expensive than aluminum or ABS.

Part complexity – deep pockets, thin walls, and tight tolerances increase machining time.

Quantity – higher volume reduces unit cost.

Finishing – anodizing, polishing, and coating add cost but improve durability.

CNC Prototyping vs CNC Production

While CNC prototyping emphasizes speed and flexibility, CNC production focuses on scalability and cost reduction. Many companies start with prototypes to refine designs, then transition to custom CNC prototyping or injection molding for volume manufacturing.

Real-World Case Example

A medical device company required 20 stainless steel housings and 50 ABS enclosures for a handheld diagnostic tool. By using CNC prototyping, the housings were machined with tight tolerances to protect sensors, while ABS enclosures were painted to simulate molded finishes. The order was completed within 10 days, enabling clinical trials and investor demos.

FAQs

What is the minimum order quantity for CNC prototyping?

Even a single prototype can be produced; CNC machining is ideal for 1–200 pcs.

Can CNC prototyping deliver optical clarity?

Yes. Acrylic and polycarbonate can be machined and polished to optical transparency.

What industries benefit the most from CNC prototyping?

Aerospace, automotive, medical devices, consumer electronics, and robotics.

How does CNC prototyping compare with 3D printing for functional testing?

CNC prototypes offer isotropic strength and production-grade performance, while 3D printed parts are weaker due to layered structures.

How long does it take to receive CNC prototypes?

Typical lead time is 2–7 days, depending on complexity and finishing requirements.

Cost Reference Examples for CNC Prototyping

The cost of CNC prototyping depends on material, part complexity, tolerance, finishing, and order quantity. The following examples illustrate typical ranges, but they are for reference only. For accurate pricing, engineers should submit CAD files and requirements to receive a detailed quotation.

| Prototype Type | Material | Size (mm) | Tolerance | Qty | Est. Lead Time | Approx. Cost (USD/part) |

|---|---|---|---|---|---|---|

| Simple Bracket | Aluminum 6061 | 80 × 40 × 20 | ±0.05 mm | 10 | 3 days | $20 – $30 |

| Gear Prototype | POM (Delrin) | Ø50 × 15 | ±0.02 mm | 50 | 5 days | $15 – $25 |

| Housing with cavities | ABS Plastic | 120 × 80 × 60 | ±0.05 mm | 30 | 7 days | $30 – $50 |

| Aerospace Bracket | Aluminum 7075 | 150 × 100 × 50 | ±0.01 mm | 5 | 7 days | $80 – $120 |

| Surgical Tool Handle | Stainless 316 | 100 × 20 × 20 | ±0.02 mm | 20 | 10 days | $70 – $100 |

Note: These prices are indicative only and may vary based on specific design requirements, order volumes, and finishing needs. Please upload your CAD drawings to JeekRapid to receive a tailored quotation.

Conclusion

CNC prototyping provides production-quality prototypes quickly and reliably. By machining real engineering materials with tight tolerances, prototypes allow engineers to validate designs, perform functional testing, and bridge to small-batch production.

Upload your CAD files to JeekRapid for a fast CNC prototyping quote. JeekRapid delivers CNC prototype services across metals and plastics, offering custom CNC prototyping and low-volume runs. As a trusted CNC prototype manufacturer in China, JeekRapid supports projects from design validation to production-ready parts.