Steel remains one of the most widely used engineering materials, but its susceptibility to corrosion in humid or chemically aggressive environments has always been a limitation. Galvanizing—coating steel with a thin but durable layer of zinc—emerged as one of the most cost-effective solutions to extend the service life of steel. Galvanized steel today is used across construction, automotive manufacturing, energy infrastructure, HVAC systems, and consumer products. Its appeal lies in the balance between durability, cost, and process versatility. Understanding the definition of galvanized steel, its strengths and weaknesses, the different galvanizing methods, and how it compares with stainless steel is essential for making informed material choices in engineering projects.

What Is Galvanized Steel? (Definition and Meaning)

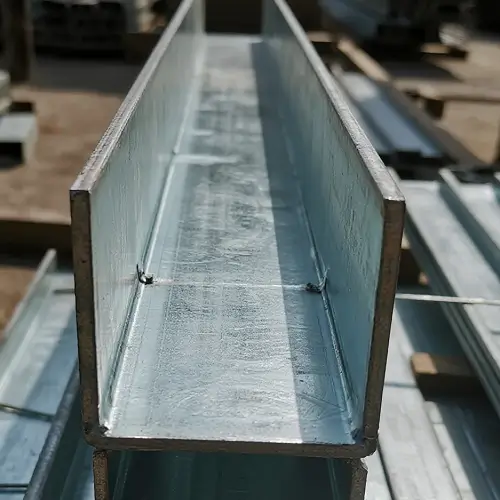

Galvanized steel is steel that has been coated with zinc to prevent rust and extend service life. The zinc forms a metallurgically bonded protective layer that shields the base steel from environmental exposure. This coating provides two types of protection. First, it acts as a physical barrier, preventing water and oxygen from reaching the steel surface. Second, zinc works as a sacrificial anode: it corrodes preferentially before the underlying steel, thereby prolonging durability.

The galvanization process can be carried out in several ways, such as immersing steel in molten zinc (hot-dip galvanizing) or applying zinc through electrochemical deposition (electro-galvanizing). Regardless of the method, the outcome is a steel product that combines mechanical strength with corrosion resistance, making galvanized steel one of the most versatile materials in engineering and manufacturing today.

Pros and Cons of Galvanized Steel

The biggest advantage of galvanized steel is its corrosion resistance. Depending on coating thickness and the surrounding environment, galvanized steel can last 20–70 years without significant maintenance. This makes it particularly cost-effective for infrastructure projects like bridges, towers, or utility poles, where replacement or repair would be expensive. The zinc coating also provides complete coverage, protecting edges, corners, and even hollow interiors, where paint or organic coatings may fail.

Another benefit is cost efficiency. Compared to stainless steel, galvanized steel offers a much lower cost per kilogram while still providing adequate protection in most outdoor environments. It is also easy to fabricate, since the galvanization process is compatible with sheet metal, pipes, and structural profiles.

However, galvanized steel is not without drawbacks. High temperatures above 200 °C can degrade the zinc layer, restricting its use in heat-intensive industries. Its appearance—a matte gray finish with a crystalline spangle—may not always meet aesthetic requirements. Welding and machining present challenges, since the zinc coating must be removed locally and restored afterward. Moreover, in aggressive marine or acidic environments, galvanized steel may underperform compared with stainless steel, limiting its application in offshore, chemical, or food-grade industries.

Galvanized Steel vs Stainless Steel

Choosing between galvanized steel and stainless steel requires weighing cost, corrosion resistance, and long-term performance.

Composition: Galvanized steel is simply carbon steel coated with zinc, while stainless steel contains at least 10.5% chromium, often alloyed with nickel and molybdenum. These alloying elements create a self-healing chromium oxide passive layer that protects stainless steel from corrosion.

Corrosion resistance: Stainless steel (grades like 304 and 316) performs exceptionally well in marine and chemical environments, where chlorides or acids are present. Galvanized steel provides robust protection in atmospheric conditions but eventually sacrifices its zinc coating over time.

Cost: Galvanized steel is significantly cheaper. For large projects such as roofing panels, fencing, or HVAC ducts, it offers excellent cost-performance. Stainless steel, while far more expensive, is essential where long-term corrosion resistance and hygiene are critical.

Processing: Galvanized steel requires care during welding and cutting, with zinc fumes needing extraction and post-treatment. Stainless steel demands careful control of heat input to avoid carbide precipitation but does not require coating repairs.

| Property | Galvanized Steel | Stainless Steel |

|---|---|---|

| Protective Mechanism | Zinc coating (sacrificial protection) | Chromium oxide passive layer |

| Corrosion Resistance | Moderate to high (atmospheric) | Very high (marine, chemical) |

| Cost | Low to moderate | High |

| Appearance | Matte gray, spangle pattern | Bright, polished |

| Typical Applications | Roofing, HVAC ducts, fencing | Marine, food processing, medical use |

Methods of Galvanizing Steel (Hot-Dip, Electro, Pre-Galvanized, Galvannealed)

Several methods are used to apply zinc coatings, each offering unique performance characteristics:

Hot-Dip Galvanizing (HDG)

Steel is cleaned, fluxed, and immersed in molten zinc at ~460 °C. The resulting zinc-iron alloy layers bond firmly to the steel, producing thick coatings of 50–100 µm that can last several decades. Hot-dip galvanized steel is the preferred choice for outdoor structures, bridges, and utility poles. Standards such as ASTM A123 and ISO 1461 regulate the coating thickness and quality.

Electro-Galvanizing (EG)

In this method, an electric current deposits zinc onto steel from an electrolyte solution. The coating is thinner (5–30 µm) but very uniform, making it suitable for automotive panels and electronic enclosures where a smooth surface is required. Electro-galvanized steel is often used when further painting or powder coating is planned.

Pre-Galvanizing

Performed at the steel mill, pre-galvanizing is a continuous process where steel coils are cleaned and passed through molten zinc. The coating is consistent and cost-effective for large quantities of sheet metal. However, when the coils are cut, exposed edges remain unprotected unless further treated.

Galvannealed Steel

This process combines hot-dip galvanizing with annealing. After dipping, the steel is heated to diffuse zinc and iron, creating a matte gray zinc-iron alloy surface. Galvannealed steel resists welding damage and offers excellent paint adhesion, making it a staple in the automotive industry.

Secondary Treatments After Galvanizing (Painting, Powder Coating, Passivation)

Galvanizing is often followed by secondary surface treatments to enhance durability or aesthetics. Passivation involves adding a thin chromate or environmentally friendly conversion layer that delays white rust formation. Painting galvanized steel is another common approach, particularly for architectural projects that require color or additional corrosion resistance. Proper surface preparation—such as degreasing, roughening, and priming—is essential for adhesion.

Powder coating over galvanized steel has become one of the most popular treatments. The process applies an electrostatically charged powder, which is then cured to form a hard, decorative finish. It is widely used in outdoor furniture, electrical cabinets, and building façades. Finally, after cutting or welding, the exposed areas of galvanized steel must be repaired using zinc-rich paint or metallizing sprays to restore protection. These secondary treatments extend the lifespan of galvanized steel and allow it to meet more demanding design requirements.

Applications of Galvanized Steel in Industry

Construction: Galvanized steel is a cornerstone of construction, used for roofing sheets, wall panels, gutters, fencing, and structural frameworks. Its corrosion resistance makes it ideal for outdoor use, while its relatively low cost allows widespread adoption. Compared to stainless steel, galvanized steel offers a more economical option for large-scale projects.

Automotive: Approximately 80% of modern car bodies are built from galvanized steel. Body-in-white panels, chassis reinforcements, and exhaust systems rely on zinc coatings to prevent rust and ensure manufacturers can offer long-term anti-rust warranties.

Energy and Infrastructure: Galvanized steel supports solar panel frames, wind turbine towers, and transmission lines. These applications demand decades of service life with minimal maintenance, making galvanizing an effective choice.

HVAC Systems: Ductwork and ventilation systems frequently use galvanized steel sheets due to their durability and ease of fabrication. The zinc coating also ensures long-term resistance to moisture and air pollutants.

Electrical and Consumer Products: Outdoor electrical enclosures, switchgear housings, washing machine panels, and outdoor furniture often incorporate galvanized steel. Its combination of durability and affordability makes it suitable for both industrial and consumer markets.

Request a Quote for Galvanized Steel Machining and Surface Treatment

JeekRapid provides precision machining and finishing services for galvanized steel components, whether for prototypes or mass production. From hot-dip galvanizing to powder coating, we deliver consistent quality across industries such as construction, automotive, and energy. For complex enclosures, structural panels, or outdoor assemblies, our engineers ensure tight tolerances and reliable corrosion protection. Upload your drawing now to request a fast, tailored quote for galvanized steel machining and surface treatment.

FAQs

How long does galvanized steel last?

Service life depends on coating thickness and environment. A hot-dip galvanized coating of 85 µm can last 50 years in rural conditions, 20–30 years in industrial or coastal regions.

Does galvanized steel rust in outdoor use?

Eventually, yes. Once the zinc coating is consumed, the base steel can rust. However, zinc sacrifices itself first, significantly delaying corrosion.

Is galvanized steel magnetic?

Yes. The zinc coating does not change the ferromagnetic properties of the steel underneath.

Can galvanized steel be welded?

It can, but welding generates zinc fumes that require proper ventilation. After welding, the affected areas should be repaired with zinc-rich coatings to restore protection.

Can galvanized steel be painted or powder coated?

Yes, provided surface preparation is done correctly. Powder coating offers both decorative and protective benefits, making it common for enclosures and architectural products.

What is the cost of galvanized steel per kg?

Costs vary depending on market conditions and coating thickness, but galvanized steel remains significantly cheaper than stainless steel, making it attractive for large projects.

Can galvanized steel be recycled?

Yes. Galvanized steel is 100% recyclable, and the zinc coating can be reclaimed and reused, aligning with sustainable manufacturing practices.

Galvanized steel vs cold rolled steel — which to choose?

Cold rolled steel offers smoother surfaces and higher dimensional accuracy but lacks corrosion protection. Galvanized steel is preferred when durability and outdoor exposure are critical.

What is galvanized steel used for in construction?

It is used in roofing, wall panels, fences, guard rails, and structural supports due to its ability to withstand weather exposure.

Is galvanized steel safe for drinking water pipes?

While galvanized pipes were historically used in plumbing, modern standards recommend alternatives such as stainless steel or plastic piping due to potential lead contamination in older galvanized pipes.