In modern manufacturing, metals often undergo extensive machining, forming, and welding before they can be used in final products. Each of these processes introduces internal stresses, changes in grain structure, or increased brittleness. Annealing is the most common and effective heat treatment to restore ductility, refine microstructure, and reduce hardness. From aerospace turbine alloys to stainless steel food-processing equipment, annealing ensures that components meet both mechanical and functional requirements. Without proper annealing, materials may crack during service or fail to achieve the required machinability in subsequent steps.

What Is Annealing?

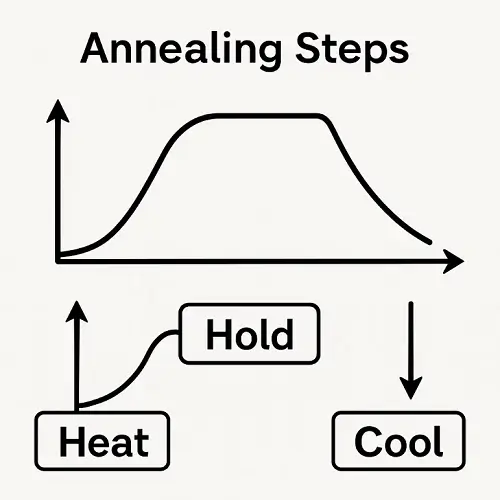

Annealing is a thermal process that involves heating a metal to a specific temperature, holding it for a defined time, and then cooling it under controlled conditions. The goal is to alter the physical and sometimes chemical properties of the metal to make it more workable. On the microscopic level, annealing promotes recrystallization, relieves internal stress, and can increase grain size depending on the cycle. For carbon steels, annealing can lower hardness significantly, while for copper and aluminum alloys, it enhances formability and conductivity.

The Annealing Process: Heating, Holding, Cooling

The process consists of three main steps. First, the metal is heated to a temperature typically above its recrystallization point. For steel, this is usually between 550–900 °C depending on carbon content, while aluminum alloys may require only 300–450 °C. The second stage is soaking or holding, where the material is kept at temperature long enough for the microstructure to homogenize. Finally, controlled cooling is applied. Furnace cooling is most common, as it provides slow, uniform cooling that helps soften the material. In some cases, air cooling or protective atmosphere cooling is chosen to prevent oxidation or speed up throughput.

Types of Annealing

Annealing is not a single process but rather a family of heat treatments, each designed for different objectives. Full annealing heats the steel to just above the critical range and slowly cools it to produce a soft, ductile structure. Isothermal annealing uses a two-step cooling approach where the material is first cooled quickly and then held at a subcritical temperature before final cooling. Spheroidizing annealing is applied to high-carbon steels to transform cementite into spherical carbides, improving machinability. Stress relief annealing is widely used after welding or machining to remove residual stresses without major changes in hardness. Recrystallization annealing is important for cold-worked metals such as copper or aluminum, restoring ductility without altering composition. Subcritical or low-temperature annealing is used when only stress removal is required, typically at 200–400 °C.

Comparative Table of Annealing Parameters for Different Metals

| Material | Typical Annealing Temperature (°C) | Purpose of Annealing | Typical Applications |

|---|---|---|---|

| Low-Carbon Steel (1018, 1020) | 650–700 | Reduce hardness, improve machinability | Automotive panels, fasteners, general fabrication |

| High-Carbon Steel (1095, Tool Steel) | 800–900 | Refine structure, spheroidize carbides | Cutting tools, bearings, high-strength components |

| Stainless Steel (304, 316) | 1,000–1,100 (followed by rapid cooling) | Stress relief, restore corrosion resistance | Food processing equipment, marine hardware, chemical tanks |

| Aluminum Alloys (6061, 7075) | 300–415 | Improve ductility, prepare for forming | Aerospace panels, automotive frames, electronics |

| Copper | 400–650 | Restore ductility, enhance conductivity | Electrical wiring, heat exchangers, plumbing parts |

| Brass | 450–650 | Prevent cracking, increase formability | Fittings, stamped parts, musical instruments |

| Titanium (Ti-6Al-4V) | 650–750 | Refine grain size, improve fatigue strength | Aerospace structural parts, biomedical implants |

| Nickel Alloys (Inconel, Hastelloy) | 950–1,050 (vacuum furnace) | Enhance toughness, reduce stress, homogenize | Turbine blades, aerospace engines, chemical reactors |

Annealing of Different Materials

Steel

Carbon steels and alloy steels respond well to annealing. Low-carbon steels (e.g., 1018) are annealed around 650–700 °C, while tool steels may require 800–900 °C to transform pearlite structures. The effect is lower hardness, improved toughness, and better machinability.

Stainless Steel

Stainless steels such as 304 and 316 require annealing at 1,000–1,100 °C, followed by rapid cooling to avoid carbide precipitation. Austenitic stainless steels benefit from stress relief annealing to prevent distortion during machining, while martensitic grades are often annealed before hardening to stabilize structure.

Aluminum Alloys

Unlike steel, aluminum alloys such as 6061 or 7075 require relatively low annealing temperatures (300–415 °C). Annealing softens the alloy, improves elongation, and allows further forming operations. Aerospace-grade aluminum is frequently annealed to achieve balance between formability and strength.

Copper and Brass

Copper annealing is critical in wire drawing, where ductility is restored after each forming step. Annealing at 400–650 °C enhances conductivity while keeping the surface clean. Brass, a copper-zinc alloy, is annealed to prevent cracking during bending or stamping operations.

Titanium and Nickel Alloys

Aerospace alloys such as Ti-6Al-4V or nickel-based superalloys require carefully controlled annealing in vacuum furnaces. This treatment helps refine microstructure, improves fatigue life, and prepares the material for subsequent machining or coating processes.

Annealing vs Other Heat Treatments

Annealing is often compared to other heat treatments, and the differences are crucial for engineers. Normalizing, like annealing, also involves heating above the critical range, but it uses air cooling, resulting in a harder and finer grain structure. Quenching rapidly cools steel in water or oil, producing high hardness but also brittleness, which requires tempering afterward. Tempering itself is applied after quenching to restore toughness. Solution treatment, commonly used for aluminum and stainless steel, differs by dissolving alloying elements into the matrix at high temperatures followed by rapid cooling.

Equipment and Process Control

Industrial annealing is performed in different types of furnaces depending on scale and precision. Batch box furnaces are versatile, while continuous annealing lines are used in large-scale steel sheet production. Vacuum furnaces are common for aerospace and medical components, where oxidation must be avoided. Protective atmospheres such as hydrogen, nitrogen, or argon are often used to maintain surface quality and prevent decarburization. Increasingly, automated controls monitor temperature curves and ensure repeatability, which is critical for industries requiring tight tolerances.

Properties and Applications of Annealed Materials

Annealed metals generally exhibit lower hardness, improved ductility, and better machinability. For example, annealed copper wires bend without breaking, annealed steels are easier to cut or form, and annealed aluminum sheets are more suitable for aerospace forming. Automotive industries rely on annealed steel for body panels, while electronics manufacturers use annealed copper for high-conductivity applications. Aerospace engines often require annealed superalloys to maintain toughness under extreme conditions.

Common Problems and Solutions

Not all annealing cycles are successful. Uneven annealing can occur when large workpieces are not uniformly heated, leading to variable hardness. Over-annealing results in coarse grains and reduced mechanical properties. Surface oxidation and decarburization are also common, especially in open-air furnaces, which is why controlled atmospheres or vacuum environments are preferred. Engineers often fine-tune time and temperature curves to avoid such defects.

FAQ

Why is annealing important?

Annealing restores ductility and relieves stress.

What temperature is used for annealing steel?

Typically 550–900 °C depending on carbon content.

How long does annealing take?

It depends on section thickness; small parts may take an hour, while large forgings require many hours.

Is annealing the same as tempering?

No, tempering reduces brittleness after quenching, while annealing softens material.

What is stress relief annealing?

A low-temperature treatment designed to remove residual stresses.

What metals need annealing?

Steel, copper, aluminum, titanium, and nickel alloys are the most common.

What is continuous annealing?

An industrial process used for large-scale steel sheet production.

Does annealing improve toughness?

Yes, it typically increases ductility and reduces the chance of cracking.

Precision CNC Machining with Heat Treatment Expertise

JeekRapid provides advanced CNC machining services combined with professional heat treatment processes such as annealing, normalizing, and tempering to optimize material properties. Our machining solutions enhance ductility, toughness, and dimensional stability of metal parts, ensuring performance in demanding applications. With state-of-the-art equipment and a skilled engineering team, JeekRapid delivers customized manufacturing solutions that meet strict industry standards. From rapid prototyping to full-scale production, JeekRapid guarantees high precision, consistent quality, and reliable delivery for every project.Get a quote!

Conclusion

Annealing remains one of the most fundamental heat treatment methods in modern industry. By carefully controlling temperature, holding time, and cooling rate, engineers can modify the structure and properties of metals to suit almost any application. Whether it is stainless steel for chemical equipment, copper wire for electronics, or aerospace alloys for high-stress environments, annealing ensures performance, reliability, and manufacturability.