Screw threads are a core feature in mechanical design, shaping how components connect, seal, and transmit motion. From precision aerospace assemblies to high-volume fastener production, the right thread type and machining method directly affect performance, reliability, and cost.

This article provides a practical guide for engineers and machinists—covering major screw thread types, relevant standards, machining processes, inspection methods, and common issues in production.

What Is a Screw Thread?

A screw thread is a helical ridge formed on the external or internal surface of a cylinder or cone. In manufacturing, screw threads are essential for fastening, sealing, and transmitting motion between components. They are found in bolts, nuts, pipe fittings, lead screws, and many other industrial parts.

In mechanical engineering, screw threads are defined by parameters such as major diameter, minor diameter, pitch, pitch diameter, and thread angle. Each standard specifies its own limits and tolerances to ensure proper fit and function.

Thread Terminology

Before selecting a machining method, most machinists will check these basic parameters:

-

Major Diameter – crest-to-crest for external threads, root-to-root for internal threads.

-

Minor Diameter – root-to-root for external threads, crest-to-crest for internal threads.

-

Pitch (or TPI) – metric threads use millimeter pitch; imperial uses threads per inch (TPI).

-

Pitch Diameter – the diameter where the thread flanks engage.

-

Thread Angle – included angle between flanks, typically 60° (ISO, Unified) or 55° (Whitworth).

Main Types of Screw Threads (Parallel vs Tapered)

Classification Overview

Screw threads in manufacturing are commonly grouped into two main styles:

-

Parallel (Straight) threads — constant diameter along the axis; typical examples: ISO Metric (M), Unified (UN/UNC/UNF), BSPP (G).

-

Tapered threads — diameter reduces along the axis to create interference for sealing; typical examples: NPT/NPTF, BSPT (R), and metric tapered pipe variants.

ISO Metric (Parallel)

Global general-purpose thread with a 60° flank angle; coarse and fine pitch series. Designated as M d × p (e.g., M10 × 1.5). Widely used in machinery and automotive assemblies.

Unified Thread Standard – UN / UNC / UNF (Parallel)

North American system with a 60° profile. UNC (coarse) suits softer materials and faster assembly; UNF (fine) supports tighter preload and vibration resistance. Classes of fit are defined per ASME standards.

British Standard Threads (Whitworth Family)

Historic BSW/BSF forms (55°) plus pipe threads:

-

BSPP (G) — parallel pipe thread, seals with gasket or washer.

-

BSPT (R) — tapered pipe thread for thread-form sealing.

NPT / NPTF (Tapered)

60° tapered pipe threads used for pressure-tight joints. NPTF is the dry-seal variant with controlled truncation for improved sealing without sealant in many cases.

“V”-Form Threads (Generic 60°)

Generic V-profile threads produced by single-point turning, taps, or dies. This term covers many straight thread applications when the specific standard is not critical.

Square Threads

High efficiency for power transmission (jackscrews, presses). Low friction, difficult to manufacture compared with V-form threads.

Acme Threads

29° trapezoidal profile; easier to machine than square threads with good load capacity. Common in lead screws, vices, and machine slides.

Buttress Threads

Asymmetric profile to carry high axial load predominantly in one direction (e.g., presses, breech locks). Combines V-form strength with square-form efficiency.

Knuckle Threads

Rounded crests and roots for rugged service and ease of forming or casting. Found on bottle necks, couplings, and hydrants.

Worm Threads

Deep 29° form used with worm gears for 90° power transfer. Similar to Acme but deeper.

Other fastening solutions such as rivets are often compared with screw threads in engineering design for load-bearing and assembly efficiency. For a detailed comparison, see this guide on rivets vs screw threads

Single- and Multi-Start Threads

Defined by the number of starts; multi-start threads increase lead for rapid linear motion at a given rotational speed.

Screw Thread Standards Overview

| Thread Type | Standard | Typical Pitch/TPI | Notes |

|---|---|---|---|

| Metric (M) | ISO 68-1 / ISO 965 | 0.25–6.0 mm | Global standard |

| UNC | ASME B1.1 | 4–40 TPI | Coarse, general purpose |

| UNF | ASME B1.1 | 12–80 TPI | Fine, precision assemblies |

| NPT | ASME B1.20.1 | 11.5–27 TPI | Sealing threads |

| BSP | BS 21 / ISO 7 | 11–28 TPI | Plumbing |

| Acme | ASME B1.5 | Variable lead | Power transmission |

Metric Thread Pitch Chart

| Nominal Size | Major Diameter (mm) | Pitch (mm) | Minor Diameter (mm) | Common Fit | Common Uses |

|---|---|---|---|---|---|

| M6 × 1.0 | 6.00 | 1.00 | 5.00 | 6g/6H | Electronics enclosures, light brackets |

| M8 × 1.25 | 8.00 | 1.25 | 6.75 | 6g/6H | Machinery covers, fixtures |

| M10 × 1.5 | 10.00 | 1.50 | 8.35 | 6g/6H | Automotive assemblies |

| M12 × 1.75 | 12.00 | 1.75 | 10.25 | 6g/6H | Industrial machinery joints |

| M16 × 2.0 | 16.00 | 2.00 | 14.00 | 6g/6H | Heavy equipment, structural parts |

Thread Machining Methods

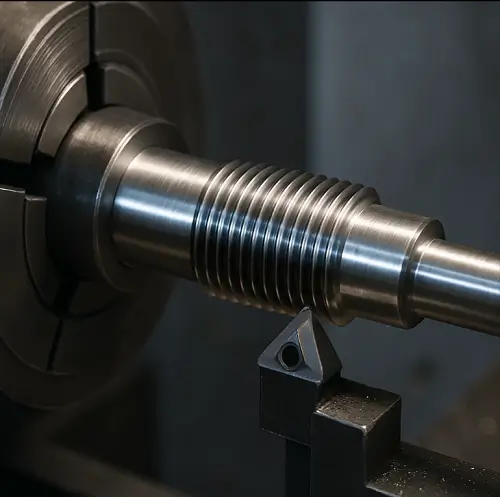

Thread Turning

Performed on a lathe with a single-point insert. Selected for large diameters or custom thread profiles. Requires rigid setup and correct tool geometry to prevent chatter.

Thread Milling

Uses a rotating cutter in a CNC mill, allowing production of different diameters with one tool. Well-suited for blind holes where a tap might break.

Tapping

Used for internal threads in small to medium holes. Spiral flute taps work well for blind holes; spiral point taps are used for through holes.

Thread Rolling

A cold-forming process that displaces material instead of cutting it. Produces stronger threads with improved surface finish, ideal for high-volume fastener manufacturing.

Tools for Thread Machining

-

Thread turning inserts matched to profile type

-

Solid carbide or indexable thread mills

-

Taps (hand, machine, forming) for different materials

-

Dies for external threads in repair or low-volume work

-

Go/No-Go gauges, pitch gauges, and thread micrometers for inspection

Common Thread Machining Defects

| Defect | Cause | Solution |

|---|---|---|

| Burrs | Tool wear, poor retraction | Use sharp tools, program proper pull-out path |

| Rough finish | Vibration, worn edges | Improve rigidity, replace inserts |

| Incorrect pitch | Programming error, thermal drift | Verify toolpath, check offsets |

| Poor fit | Wrong tolerance or expansion | Follow standard, measure under stable conditions |

Thread Inspection and Quality Control

Most workshops perform a quick check with a go/no-go gauge. For higher accuracy, machinists use thread micrometers or the three-wire method to measure pitch diameter. Optical comparators help verify profile shape, especially on precision components.

Applications of Threads

-

Automotive – UNC/UNF bolts for chassis and engines, metric threads for assemblies

-

Aerospace – fine threads for fatigue resistance in critical structures

-

Plumbing – NPT/BSP for leak-proof joints under pressure

FAQs

Q1: What is the difference between UNC and UNF screw threads?

From a machinist’s perspective, UNC is faster to cut and holds better in softer metals, while UNF allows finer adjustment and better preload control in critical joints.

Q2: How to measure screw thread pitch accurately?

In the workshop, a pitch gauge is the first choice for a quick check. For inspection reports, the three-wire method or an optical comparator is preferred.

Q3: Can NPT and BSP screw threads be used together?

They may appear similar, but the angles and pitches differ. Mixing them often causes leaks—matching standard to standard is recommended.

Q4: What is the strongest type of screw thread?

For fasteners, fine threads generally offer better tensile strength; for power transmission, Acme or square threads maintain strength over time.

Q5: What is the standard tolerance for metric threads?

General-purpose work uses 6g (external) and 6H (internal). Precision fits may require 4H/5H depending on the assembly requirements.

Conclusion

Threading involves more than cutting a spiral—it is about matching geometry, tolerance, and surface finish to the job’s requirements.

At JeekRapid, threading is integrated into CNC workflows from prototype to mass production, with process control at every step to ensure fit, function, and durability.

For detailed pricing or a manufacturability review of threaded components, send CAD files or drawings to JeekRapid. The team will respond with a quotation and machining plan, helping projects move from design to production efficiently.

For custom-threaded parts or technical advice on manufacturability, JeekRapid’s engineering team can review your drawings and provide a detailed machining quote within 24 hours.