In the product development lifecycle, the transition from design to production often hinges on the reliability of early prototypes. Among various prototyping methods, CNC (Computer Numerical Control) machining remains the most dependable and widely adopted approach for engineering validation before mass production. This article explores the technical advantages of CNC prototyping and its crucial role in reducing design risks, verifying manufacturability, and accelerating product development timelines.

Achieving Dimensional Accuracy and Tolerance Control with Subtractive Manufacturing

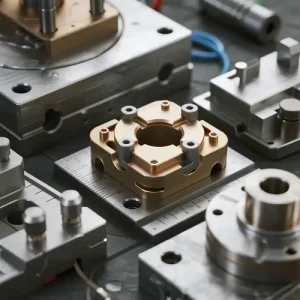

CNC machining offers superior precision by subtracting material from solid metal or plastic blocks, delivering components with tolerances typically within ±0.05 mm or better. This level of dimensional accuracy is critical for applications requiring tight mechanical fits, sealing interfaces, or alignment-sensitive assemblies.

Prototyping with CNC machining enables engineers to validate critical tolerances early in the product development process. This is especially valuable in industries such as medical devices, aerospace, and automotive manufacturing, where deviations in features can compromise functionality or regulatory compliance. Compared to additive manufacturing techniques like FDM or SLA, CNC prototyping consistently provides better dimensional stability and repeatability, making it a preferred method for fit-critical components.

Enabling Functional Testing with Production-Grade Materials

Unlike many prototyping methods that rely on simulation-grade or composite materials, CNC machining allows prototypes to be fabricated from actual production-grade substrates such as aluminum alloys (e.g., 6061-T6, 7075), stainless steels (304, 316), and engineering plastics like POM and PC. This material fidelity provides realistic performance evaluation in terms of mechanical strength, thermal conductivity, wear resistance, and chemical compatibility.

For example, aerospace component prototypes often require precise thermal dissipation properties, achievable only with specific aluminum alloys. By utilizing CNC prototyping with production-grade materials, teams gain actionable insights into structural integrity and environmental resistance before committing to tooling.

Fast Turnaround for Low-Volume Prototyping Without Tooling Overhead

Speed is a critical factor in today’s fast-paced product development cycles. CNC prototyping is highly effective for low-volume production runs—typically from one to twenty units—without the costs or lead times associated with injection molds or casting dies. At JeekRapid, CNC prototypes are typically delivered within 3 to 7 working days depending on part complexity and material availability.

This rapid delivery supports iterative design and testing cycles, allowing teams to refine geometry, functionality, or manufacturability without costly delays. Unlike traditional molding methods, CNC prototyping allows immediate design updates through CAM programming, facilitating faster time-to-market.

Validating Manufacturability and Reducing Pre-Production Risk

Early validation through CNC prototypes helps reduce financial and technical risks tied to premature tooling investment. By testing prototypes manufactured to production specifications, teams can confirm functionality, manufacturability, and compatibility with downstream processes such as surface finishing, welding, or assembly.

Case studies from automotive and electronics sectors reveal how CNC prototyping identified issues such as excessive insertion forces or insufficient clearances, which were corrected prior to mold fabrication. This risk mitigation prevents costly tooling revisions and production delays.

Supporting Design for Manufacturability (DFM) and Production Planning

CNC prototypes built with production-grade materials and precise tolerances serve as essential references for DFM reviews, fixture design, and quality assurance planning. These validated physical samples streamline transitions to full-scale manufacturing by facilitating tolerance stack-up studies and inspection fixture development.

With CNC prototypes, engineers and manufacturing teams can collaboratively optimize designs to meet production constraints, reducing non-conformance risks and improving overall process efficiency.

Enhancing Cross-Functional Communication and Stakeholder Alignment

High-fidelity CNC prototypes foster clearer communication among design, engineering, manufacturing, and clients. Physical prototypes enable stakeholders to review and handle components, supporting discussions on fit, finish, ergonomics, and feasibility. This collaborative approach accelerates decision-making and reduces misunderstandings in remote or cross-functional teams.

Strengthening Regulatory and Customer Validation Processes

In regulated industries such as medical devices and aerospace, CNC prototypes are often integral to regulatory submissions, first article inspections, and customer acceptance tests. Fabricated with production-grade materials and processes, these prototypes meet the necessary standards for documentation and traceability.

By using CNC machining for prototyping, companies ensure compliance and build trust with customers and regulators, supporting a smoother path from prototype to production.

Conclusion

CNC machining remains a cornerstone of modern prototyping strategies, offering unmatched precision, material authenticity, and rapid iteration. Whether refining complex assemblies, validating manufacturability, or mitigating risks before tooling, CNC prototypes provide an indispensable bridge from digital designs to production reality.

At JeekRapid, we specialize in high-precision CNC prototyping tailored to diverse industries including medical, aerospace, automotive, and consumer electronics. Our experienced engineering team collaborates closely with clients to ensure prototypes meet dimensional and functional requirements while optimizing for manufacturing efficiency.

If you are looking for high-quality, fast-delivered CNC prototype services, JeekRapid can tailor professional solutions for you with advanced equipment and rich experience to help your product development project proceed smoothly. Click the link below to get a unique quote now, and let us work together to push your innovation from design drawings to physical samples!