Grinding Services – The Ideal Choice for High-Precision Components

In high-precision manufacturing, grinding is a key process for achieving tight dimensional tolerances and superior surface finishes. Jeek provides professional grinding services to meet the demanding requirements of prototyping and precision parts production with exceptional accuracy and consistency.

Quality Assurance

ISO 9001:2015 certified to ensure high quality.

Tight Tolerance

Precision control within ±0.050mm.

In-House Workshop

with advanced machinery and experienced team.

Fast Delivery

1 to 10,000 parts in as fast as 3 days.

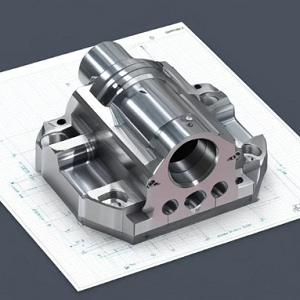

What is Grinding?

Grinding is a machining process that uses a high-speed rotating abrasive wheel to remove material from the surface of a workpiece. It allows for micron-level dimensional control and excellent surface smoothness. Widely used for finishing hard materials and precision components, grinding is an essential part of advanced manufacturing.

Grinding types offered by jeek

Surface Grinding

Precision flat finishing for molds, plates, and fixtures.

Cylindrical Grinding

Precision outer diameter finishing for shafts and sleeve parts.

Internal Grinding

High-precision finishing for internal holes or inner walls of components.

Centerless Grinding

Efficient processing of small parts with high concentricity.

Why choose Jeek grinding services? How to get a Grinding Quote?

With high-precision grinders and experienced operators

Strictly follow ISO 9001:2015 quality system

Supports orders from 1 prototype to 10,000 pieces in batches

Provide one-stop CNC + surface treatment solutions

01

Upload CAD Files

02

Get Quote And Analyze

03

Order Confirmation

04

Shipping Address

The difference between grinding and traditional machining

Grinding uses high-precision grinders and advanced CNC technology to achieve micron-level dimensional control, with tolerances as precise as ±0.005 mm. It can process parts with extremely high precision, surface finish and complex shapes, and is widely used in mold manufacturing, aerospace, medical equipment and other fields. Compared with traditional machining methods, grinding can provide higher precision in surface treatment, especially for surface finishing of hard materials and precision parts.

Traditional machining mainly relies on manual operation, with low precision, and tolerances are usually around ±0.1 mm, which is suitable for parts with simple structures and low precision requirements. Grinding not only provides a higher level of automation, but also ensures the quality and consistency of parts, especially suitable for mass production that requires precision surface treatment.

Get started quickly

Production of your parts

We ensure that all information provided and uploaded content is kept strictly confidential and secure.