CNC Machining Services.

At Jeek Rapid, we provide precision CNC machining services for a wide range of industries including automotive, aerospace, medical, and electronics. Whether you need rapid prototyping or production, our advanced CNC equipment ensures tight tolerances, fast turnaround, and high repeatability.

Jeek - A Leading Parts Manufacturer In China's CNC Industry

Providing

On-Demand CNC Machining Services

We specialize in providing our customers with efficient and precise CNC machining solutions. Whether it is prototyping or mass production, our CNC machining services can meet different needs and ensure that the project is delivered to you smoothly and on time.

No MOQ. Available from single piece to batch

The advanced workshop is always in operation to ensure on-time delivery.

Send to email and reply within 12 hours.

Achieve ±0.05mm precision tolerance and Ra0.2μm surface roughness

What Are Our Machining Technologies?

We have a variety of processing technologies such as CNC milling, CNC turning, CNC grinding, EDM and wire cutting, and can process a variety of materials such as aluminum alloy, stainless steel, plastic and composite materials. With ISO 9001 quality management system certification and advanced CNC equipment, we are able to maintain high precision in each production link to ensure consistent part quality.

Whether you are looking for rapid prototyping or mass production, Jeek can provide customized processing services according to your needs to help you maintain market competitiveness and improve product quality.

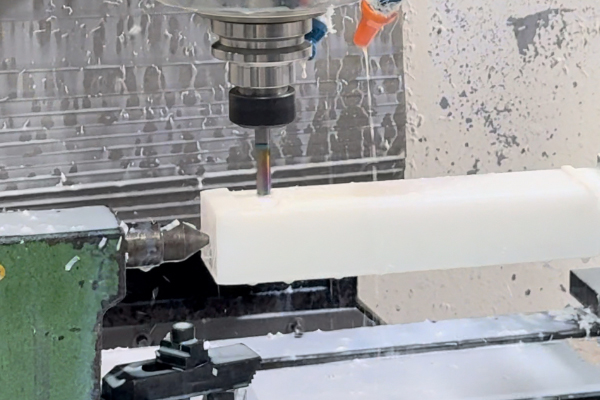

CNC Milling

CNC milling is a technology that utilizes computer programs to control milling machines for precision machining. Compared to traditional milling, it enables high-precision processing of complex geometric shapes and supports a variety of materials, including metals and plastics. By precisely controlling tool paths and cutting parameters through program code, CNC milling ensures consistent part quality, enhances production efficiency, and reduces human error. This makes it an ideal choice for mass production and the machining of intricate components.

CNC Turning

CNC turning is a machining process that uses computer-controlled lathes to manufacture parts. Compared with conventional turning, CNC turning relies on digital programming to precisely control tool paths and cutting parameters, enabling the production of complex rotational components such as shafts and discs. It offers high repeatability and consistency, making it ideal for mass production. CNC turning is mainly used for metal materials and is also applicable to plastics and composites. It is widely applied in industries such as automotive and aerospace

5 Axis CNC Machining

5-axis CNC machining is an advanced manufacturing technology that simultaneously controls tool movement along five axes, enabling complex geometries to be machined in a single setup. Compared with conventional 3-axis machining, it significantly reduces re-clamping, improves accuracy and efficiency, and is ideal for producing high-precision components in aerospace, medical, and other demanding industries. Its key advantage lies in multi-angle accessibility, allowing more flexible tool paths and minimizing machining blind areas.

Grinding

Grinding is a high-precision process that uses a high-speed rotating grinding wheel to perform micro-cutting on the surface of a part. In this way, micron-level dimensional accuracy and extremely high surface finish can be achieved. Grinding is widely used in the processing of hard materials and the surface finishing of precision parts, especially in mold manufacturing, shaft parts and other fields. Jeek provides a variety of grinding services, including surface grinding, external cylindrical grinding, internal hole grinding, etc., to ensure high consistency in shape and surface quality of each part.

EDM

EDM is a non-traditional precision machining process that removes material through a series of controlled electrical discharges between an electrode and the conductive workpiece. The process generates localized thermal energy to erode material without direct mechanical contact, making it well-suited for machining hardened steels, superalloys, and complex geometries. EDM is widely used for producing intricate features, deep cavities, sharp internal corners, and tight-tolerance components that are difficult or impossible to achieve with conventional CNC cutting methods.

Wire Cut

Wire Cut (Wire Electrical Discharge Machining, Wire EDM) is a precision machining process that uses a continuously fed electrically charged wire to cut conductive materials through controlled electrical discharges. Material is removed by localized thermal erosion without physical contact, enabling highly accurate cutting of complex profiles, fine features, and tight tolerances. Wire EDM is particularly suitable for machining hardened metals, precision tooling, and intricate components that require excellent dimensional accuracy and superior edge quality.

What Are the Benefits of Choosing Our Jeek CNC Machining?

Choosing Jeek CNC machining, you will enjoy the full support of a professional team, the precise operation of top-notch equipment, and cost-effective customized services. Regardless of the size of the order, we always ensure excellent precision and quality, while providing efficient DFM optimization and personalized collaboration, easily coping with complex machining challenges, and delivering at an industry-leading speed to ensure that your project is efficiently advanced.

A Team of Highly Skilled Engineers

Modern High-Precision Machining Qquipment

Flexible and Transparent Pricing Strategy

Customized services and full technical support

Multi-material & process Machining capabilities

Fast response delivery cycle

We are The Partner That You Can Trust for Every Project.

Choose us for rapid CNC prototyping and low-volume production with competitive pricing and superior-quality parts.

Jeek Offers Highly Individual, Customized Machining Solutions.

We specialize in providing tailored machining services for small batch production, especially for end-use parts that require high precision and fast delivery. With advanced manufacturing technology and a wide range of material options, we are able to flexibly respond to complex design requirements and ensure that each part meets strict quality standards. Whether it is prototyping or small-scale mass production, our team can provide efficient and reliable solutions to help you accelerate your product launch.

Whether your needs are 50 or 10,000 pieces, we can provide professional and efficient custom machining services at a very competitive price to meet your diverse production needs.

CNC machining empowers the future with precision. From aerospace to medical technology, from smart robots to the automotive industry, we carefully carve every CNC machining part to help you achieve unlimited possibilities.

Prototype Design Verification

Functional Testing Complex Designs

Create Metal Molds and Tooling

High Performance Machined Medical Components

Machinable Custom Automotive Parts

High Precision Machined Aerospace Components

Clear Optical Prototypes With Precision CNC Machining

Low-Volume Machined Parts of End-Use

CNC Machining Materials Support

Stainless Steel

Stainless steel is distinguished by its excellent corrosion resistance, high mechanical strength, and outstanding durability. Stainless steel components are widely used across industries such as medical devices, food processing, chemical equipment, and industrial machinery, where reliability, hygiene, and structural integrity are critical.

Titanium

Titanium possesses high strength, low density, and excellent corrosion resistance. Thanks to its superior fatigue resistance and biocompatibility, titanium alloy components are widely used in aerospace, medical, marine, and high-performance industries—fields requiring high strength, low density, and high corrosion resistance.

Aluminum

Lightweight, easy to process, and possessing good thermal conductivity are the core characteristics of aluminum and aluminum alloys. Aluminum and aluminum alloy components have an extremely wide range of applications, appearing in almost every industry, but they are particularly popular in the aerospace and consumer electronics sectors.

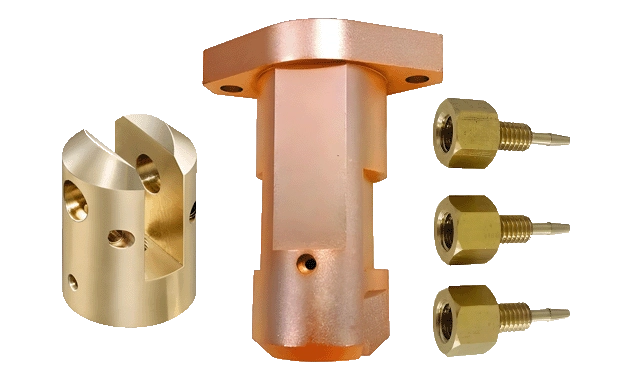

Brass

Stainless steel is distinguished by its excellent corrosion resistance, high mechanical strength, and outstanding durability. Stainless steel components are widely used across industries such as medical devices, food processing, chemical equipment, and industrial machinery, where reliability, hygiene, and structural integrity are critical.

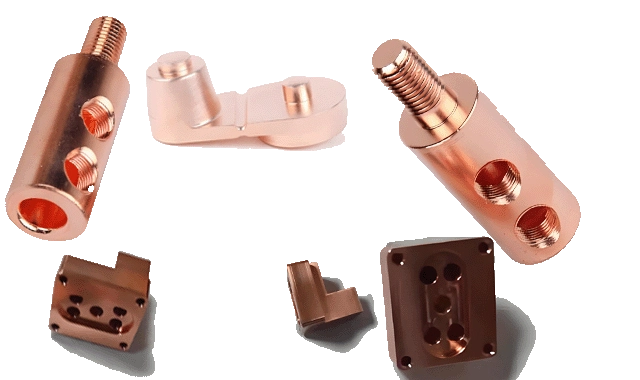

Copper

Copper is known for its outstanding electrical and thermal conductivity, high ductility, and corrosion resistance. Copper components are widely applied in electrical systems, heat exchangers, motors, and electronic products where efficient energy transfer is essential.

Carbon Steel

Carboan steel provides high strength, good toughness, and cost-effective machinability. Its mechanical properties can be tailored through heat treatment, making it widely used in automotive parts, industrial equipment, and structural applications.

We are not limited to processing only the materials shown above; we have virtually no material limitations. If you don’t find what you’re looking for above, please contact us.

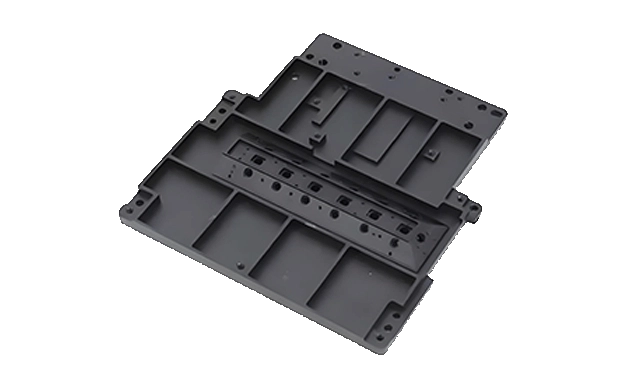

POM

POM (polyoxymethylene), also known as acetal, is a high-performance engineering thermoplastic distinguished by its high stiffness, excellent dimensional stability, low friction coefficient, and outstanding wear resistance. POM components are widely used across many industries, especially in automotive, industrial machinery, and precision mechanical systems, where reliable performance, tight tolerances, and long-term durability are required.

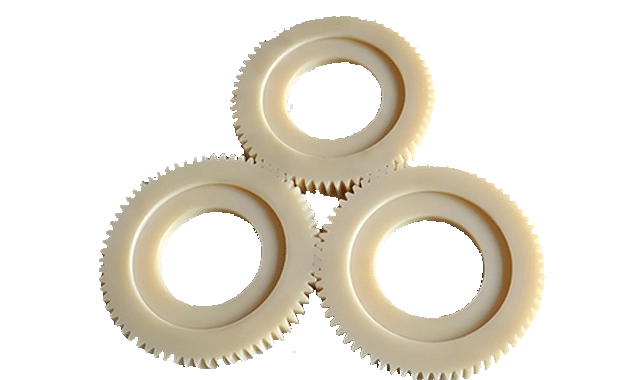

Nylon(PA)

Nylon (polyamide) is a versatile engineering thermoplastic known for its high mechanical strength, excellent toughness, and good resistance to fatigue and abrasion. Nylon parts are widely used in automotive, industrial equipment, and electrical applications, particularly for gears, bushings, housings, and structural components that require a balanced combination of strength, impact resistance, and machinability.

PEEK (Polyether Ether Ketone)

PEEK is a high-performance thermoplastic offering exceptional mechanical strength, excellent chemical resistance, and outstanding thermal stability. PEEK parts are extensively applied in aerospace, medical, semiconductor, and energy industries, especially in demanding environments that require high temperature resistance, chemical durability, and long-term mechanical reliability.

PTFE (Polytetrafluoroethylene)

PTFE is a fluoropolymer well known for its extremely low coefficient of friction, excellent chemical inertness, and wide service temperature range. PTFE components are widely used in chemical processing, sealing systems, and electrical insulation applications, where non-stick behavior, corrosion resistance, and thermal stability are critical.

PC (Polycarbonate)

Copper is known for its outstanding electrical and thermal conductivity, high ductility, and corrosion resistance. Copper components are widely applied in electrical systems, heat exchangers, motors, and electronic products where efficient energy transfer is essential.

PPS (Polyphenylene Sulfide)

PPS is a high-performance engineering thermoplastic known for its excellent chemical resistance, inherent flame retardancy, and outstanding dimensional stability at high temperatures. PPS components are widely used in automotive, electronics, and industrial fluid handling systems.

We are not limited to processing only the materials shown above; we have virtually no material limitations. If you don’t find what you’re looking for above, please contact us.

Surface Treatment Section Briefly

Surface treatment can improve the performance and aesthetics of parts. Common methods include:

Mechanical Treatment

Polishing: improve surface finish and enhance aesthetics.

Sandblasting: improve surface texture and increase coating adhesion.

Chemical Treatment

Anodizing (mainly for aluminum): Enhances corrosion resistance and provides a variety of color options.

Electroplating: Such as chrome plating and nickel plating, improves wear resistance and corrosion resistance.

Coating Treatment

Powder coating: Provides durable and beautiful surface protection.

PVD coating: Improves hardness and wear resistance, and is widely used in tools and molds.

Heat Treatment

Quenching: Improves metal hardness and strength.

Nitriding: Enhances surface wear resistance and fatigue strength.

If you have more complex surface finishing requirements, please contact the [email protected]

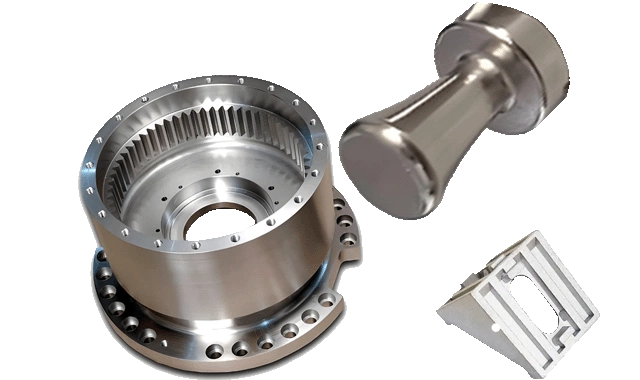

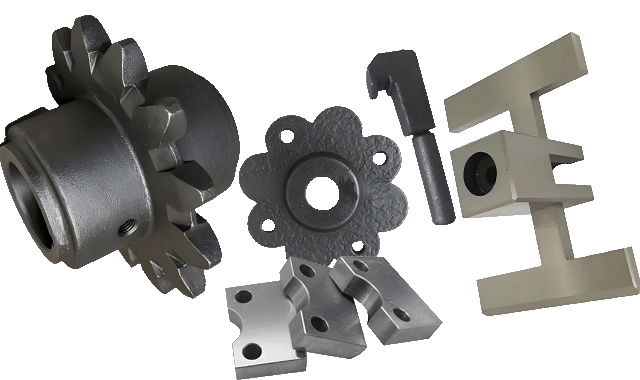

Metal CNC Machining

We support CNC machining of a variety of high-performance engineering plastics, covering more than 30 material options. Whether it is precision parts or functional components, our processed plastic products fully meet the functional requirements and can be fully tested for performance to meet the stringent needs of various industries from medical to electronics.

Plastic CNC Machining

From complex prototypes to high-precision mass-produced parts, our CNC metal machining services meet various challenges with excellent technical strength. Whether it is lightweight aluminum alloy, high-strength stainless steel or corrosion-resistant titanium alloy, we can achieve precision machining. Jeek guarantees fast delivery and stable quality to help your project move forward efficiently.

Ceramic CNC Machining

With advanced CNC machining technology, we can process complex and durable ceramic parts and precisely manufacture various high-performance ceramic components. Utilizing CNC milling, grinding, and turning, we achieve tight tolerances and excellent surface finishes, delivering high-quality, wear-resistant, and heat-resistant ceramic parts. All finished products undergo quality testing to ensure compliance

Welding Technology

Jeek provides a variety of advanced welding processes to meet the different connection requirements of high-precision metal parts in terms of strength, sealing, aesthetics, etc. Whether it is the precision welding of tiny parts or the high-strength connection of large structures, our engineering team can achieve high-quality welding results with stable and reliable processes.

Put Your CNC Parts into Production Today.

What is CNC Machining

CNC machining, the full name of which is Computer Numerical Control, is a technology that uses pre-programmed digital instructions to control machine tools for automated machining. It uses CAD (computer-aided design) models to generate CAM (computer-aided manufacturing) programs to drive machine tools to perform cutting, drilling, milling and other operations on metals, plastics and other materials, thereby manufacturing high-precision parts or products.

The core advantages of CNC machining lie in its high precision, high repeatability and high efficiency. It can achieve the machining of complex geometric shapes, meet strict tolerance requirements, and is suitable for a variety of needs from prototyping to mass production. Through multi-axis linkage (such as 3-axis, 4-axis, 5-axis), CNC technology can complete complex structures that are difficult to achieve with traditional machining.

In the manufacturing industry, CNC machining is widely used in aerospace, automotive, medical, electronics and other fields, and is an indispensable key technology for modern precision manufacturing.

Project Spotlight: Titanium CNC Prototype

We recently worked with a European medical device company to produce precision titanium components using 5-axis CNC machining. The parts had ultra-fine internal features and required a tolerance of ±0.01mm. From DFM review to production and inspection, we delivered the prototypes in just four working days.

This case highlights JeekRapid’s ability to deliver fast, high-precision machining services for industries where timing and accuracy matter most—like medical, aerospace, and robotics.

CNC Machining FAQs

What materials are suitable for CNC machining?

CNC machining is suitable for a variety of materials, including metals (such as aluminum, stainless steel, titanium alloy), plastics (such as POM, nylon, PEEK) and composite materials (such as carbon fiber). The specific choice depends on the performance requirements and application scenarios of the parts.

How accurate can CNC machining be?

Our CNC machining accuracy can usually reach 0.01 mm, depending on the machine tool performance, tool selection and processing technology. For high-precision parts, if combined with grinding parts, the accuracy can reach 0.003.

What is the minimum order quantity for Jeek CNC machining?

Our CNC machining supports a variety of order requirements from single-piece prototypes to mass production. Whether it is 1 piece or 10,000 pieces, we can flexibly arrange production according to customer needs.

What is the delivery cycle of CNC machining?

The delivery cycle depends on the complexity of the part and the order quantity. Generally speaking, the delivery cycle for simple parts is 3-5 days, and complex parts may take 1-2 weeks. We will also expedite machining according to customer needs.

What are the surface treatment options for CNC machining?

After CNC machining, a variety of surface treatments can be performed, such as polishing, sandblasting, anodizing, electroplating, powder coating, etc. These treatments can not only improve the appearance of the parts, but also enhance their wear resistance, corrosion resistance and other properties.

Get Quote Now to Start Your CNC Machining Project

Let us provide solid manufacturing support for your creativity with precise craftsmanship and efficient services.