Product Development

Jeek provides efficient product development services across various industries, specializing in rapid prototyping and validation. Through precise machining processes and streamlined production workflows, we ensure that every design undergoes rigorous testing within a short timeframe to meet functional requirements. Whether for functional validation or material testing, we guarantee thorough early-stage verification to minimize development risks.

Jeek provides full support at all stages of product development. From initial design and prototype development to subsequent mass production, we ensure that every detail meets the standards. Through this efficient process, we help customers optimize the design and smoothly transition from concept to mass production.

Why manufacture

aerospace parts

using Jeek?

ISO Certification

Jeek has passed ISO 9001:2015 certification and strictly implements international quality standards.

Extreme Environment Resistance

Parts must withstand high and low temperatures, high speeds and other operating conditions to ensure long-term stable operation.

Lightweight Design

Use high-strength, low-weight materials to improve fuel efficiency and flight performance.

Reliability and Durability

Some parts in product development are designed with a long service life and are suitable for high-intensity usage scenarios.

High-Precision Manufacturing

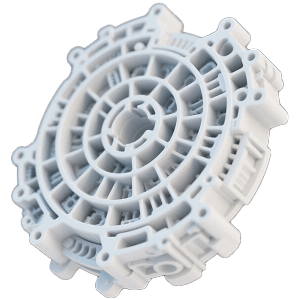

Advanced CNC machining and 3D printing technologies enable complex structures and small tolerances.

Industry Standards

Strictly follow the requirements of the aerospace industry and comply with the AS9100 quality management system.

(Jeek) Realizes customized services for product development

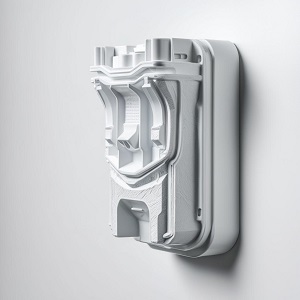

From concept to product, Jeek provides efficient and reliable prototyping solutions for all kinds of product development. We combine CNC machining, 3D printing and other processes to provide full-process support from early design verification to small batch trial production, helping customers optimize product performance.

Machining processes and applications of product development materials

A list of common materials, machining processes, and typical applications used in product development

| Material Type | Processing Technology | Application |

|---|---|---|

| ABS Plastic | 3D Printing, Injection Molding | Prototype housings, Functional test parts |

| Aluminum | CNC Machining | High-end consumer product prototypes (e.g., electronic enclosures) |

| Silicone | Injection Molding, Manual Molding | Wearable prototypes, Medical consumer products |

| Resin Materials | SLA 3D Printing | Precision models, Small batch test parts |

| Stainless Steel | CNC Machining, Metal Printing | Functional testing parts, Durable housings |

Advantages of product development parts

Design verification, improve development efficiency

Through prototype manufacturing, Jeek helps engineers verify the design in the early stage, ensure the accuracy of part size, shape and assembly, identify potential problems in advance, thereby avoiding design errors in the formal production stage and improving development efficiency.

Performance testing and optimization

By manufacturing functional prototypes, our team can conduct multiple tests, including strength, heat resistance, wear resistance, etc., optimize material and structural design, and ensure the reliability and performance of parts in different working environments.

Production Feasibility Analysis

Prototype manufacturing not only validates the design but also provides data support for mass production. It evaluates machining processes, assembly workflows, production costs, and other factors, helping clients prepare for mass production and ensuring a smooth project transition.

Fast delivery, accelerate product launch

Compared with traditional manufacturing methods, our rapid prototyping cycle is short and can quickly respond to design modification requirements, thereby accelerating the product development process.

Low-cost trial production, reduce risks

Through small-batch trial production, we can effectively reduce the cost risks caused by design or production problems, provide more flexibility for mass production, and help customers avoid potential development risks in the early stages of the project.

More production process options

Frequently Asked Questions

Jeek is ISO 2015 certified, adhering to strict international standards in production and quality management, providing customers with high-quality standards and precision manufacturing services.

Jeek CNC machining services are applicable to multiple industries, such as aerospace, automotive, medical devices, etc. We use high-precision equipment and advanced technology to process complex parts and ensure reliability and performance under extreme working conditions. Our team will develop the most optimized machining solutions based on the special needs of each industry to meet customers’ high standards for precision, quality and delivery.

After completing prototype development, we will conduct functional verification and performance testing to ensure that the design meets expectations. Once confirmed, we will quickly transition to mass production.

Get started quickly

Production of your parts

We ensure that all information provided and uploaded content is kept strictly confidential and secure.