Industrial Machinery

Jeek Providing customized component solutions for the industrial machinery sector, we specialize in manufacturing high-precision, highly durable, and structurally complex mechanical parts. Through advanced machining processes and rigorous quality inspections, each component is ensured to operate reliably under high loads and harsh environments, meeting the industry’s strict requirements for performance, reliability, and durability.

Jeek provides customized component solutions for the industrial machinery sector, specializing in the manufacturing of high-strength, wear-resistant, and complex geometrical precision parts. Through advanced machining processes and strict quality control, each component maintains excellent performance even in harsh industrial environments, meeting the industry’s stringent requirements for reliability, precision, and durability.

Why manufacture

Industrial Machinery

using Jeek?

ISO certification

Jeek has passed ISO 9001:2015 certification and strictly implements international quality standards.

Extreme environment resistance

Parts must withstand high and low temperatures, high speeds and other operating conditions to ensure long-term stable operation.

Lightweight design

Use high-strength, low-weight materials to improve fuel efficiency and flight performance.

Reliability and durability

Industrial machinery components are designed to have a long service life and are suitable for high-intensity use scenarios.

High-precision manufacturing

Advanced CNC machining and 3D printing technologies enable complex structures and small tolerances.

Industry standards

Strictly follow the requirements of the aerospace industry and comply with the AS9100 quality management system.

(Jeek) Prototyping and manufacturing of industrial equipment

In the industrial manufacturing sector, precision and durability are crucial. Jeek leverages advanced machining processes to provide customized prototype design and manufacturing services for various industrial equipment. From structural validation to functional testing, we respond quickly to demands, ensuring every component meets rigorous application requirements, driving efficient production and technological advancements.

Processing and applications of industrial equipment prototype design materials

A list of commonly used industrial machinery materials, machining processes, and typical applications.

| Material Type | Processing Technology | Application |

|---|---|---|

| Aluminum | CNC Machining, Die Casting | Industrial equipment housings, Structural supports |

| Engineering Plastics (POM, PA) | Injection Molding, CNC Machining | Gears, Pulleys, Mechanical parts |

| Steel | Welding, Laser Cutting | Frames, Support structures |

| Stainless Steel | CNC Machining, Laser Welding | Valves, Pump components |

| Carbon Fiber Composites | 3D Printing, Hand Lay-up | Industrial automation components |

Advantages of prototyping and manufacturing of industrial equipment

Design verification, optimized product structure

Prototyping allows engineers to visually check the design of industrial equipment at an early stage, verify the size, structure and assembly method, avoid the additional cost of later modifications, and improve overall development efficiency.

Rapid iteration, shorten development cycle

Compared with traditional manufacturing methods, Jeek has a shorter production cycle for prototyping, can quickly respond to design adjustment needs, speed up product development progress, and allow industrial equipment to enter the market faster.

Small batch trial production, reduce investment risks

Small batch trial production before formal mass production can detect potential problems in advance, reduce losses caused by design or production defects, and reduce risks.

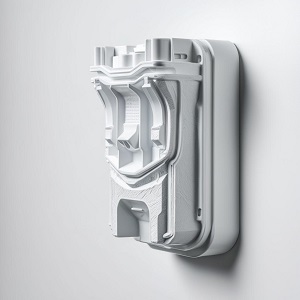

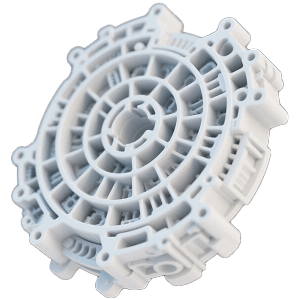

Jeek industrial machinery parts

Over the years, Jeek has provided high-quality parts solutions for most companies’ industrial machinery industry with its rich manufacturing experience and precision machining capabilities. Whether it is high-strength structural parts, complex transmission parts, or precision accessories, we can meet customer needs through CNC machining, sheet metal manufacturing and other processes to ensure the durability and stability of its parts. The following is a display of some of our industrial machinery parts.

More production process options

Frequently Asked Questions

Jeek is ISO 2015 certified, adhering to strict international standards in production and quality management, providing customers with high-quality standards and precision manufacturing services.

Jeek CNC machining services are applicable to multiple industries, such as aerospace, automotive, medical devices, etc. We use high-precision equipment and advanced technology to process complex parts and ensure reliability and performance under extreme working conditions. Our team will develop the most optimized machining solutions based on the special needs of each industry to meet customers’ high standards for precision, quality and delivery.

After completing prototype development, we will conduct functional verification and performance testing to ensure that the design meets expectations. Once confirmed, we will quickly transition to mass production.

Get started quickly

Production of your parts

We ensure that all information provided and uploaded content is kept strictly confidential and secure.