Aerospace parts

Jeek provides customized component solutions for the aerospace industry, specializing in the manufacturing of high-strength, high-temperature-resistant, and complex geometric precision parts. Through advanced machining processes and strict quality control, each component maintains excellent performance under extreme conditions, meeting the aerospace industry’s rigorous requirements for reliability, precision, and durability.

At Jeek, we leverage advanced manufacturing technology and extensive engineering expertise to provide customized prototype design and manufacturing services for the aerospace industry. From initial design verification to mass production, we employ advanced machining processes and strict quality control to ensure that each aerospace component operates reliably in harsh conditions. Whether it’s for R&D test samples or large-scale production of critical components, Jeek is committed to supporting your aerospace projects efficiently and cost-effectively, fostering technological innovation and breakthroughs.

Why manufacture

aerospace parts

using Jeek?

ISO Certification

Jeek is ISO 9001:2015 certified, ensuring that aerospace parts meet stringent quality standards and consistency requirements.

Extreme Environment Resistance

Parts must withstand high and low temperatures, high speeds and other operating conditions to ensure long-term stable operation.

Lightweight Design

Use high-strength, low-weight materials to improve fuel efficiency and flight performance.

Reliability and Durability

Aerospace parts are designed for long life and are suitable for high-intensity use scenarios.

High-Precision Manufacturing

Advanced CNC machining and 3D printing technologies enable complex structures and small tolerances.

Industry Standards

Strictly follow the requirements of the aerospace industry and comply with the AS9100 quality management system.

Rely on Jeek expertise to achieve accurate design and efficient manufacturing of aerospace prototypes.

In the aerospace field, every component must exhibit impeccable precision and outstanding performance. For years, Jeek has specialized in aerospace prototype design and manufacturing, accumulating extensive experience in producing both simple parts and complex systems. We utilize advanced processing techniques and multi-stage quality control processes to ensure that each product undergoes rigorous testing and certification, meeting international standards. Contact us now for design quotes and explore high-quality solutions tailored for the aerospace industry.

Machining of aerospace manufacturing materials and their applications

List of various commonly used aerospace materials, machining technologies and typical applications

| Material Type | Machining Technology | Application |

|---|---|---|

| Aluminum | CNC machining, laser cutting | Fuselage structure, wing frame |

| Titanium Alloy | CNC machining | Engine parts and connectors |

| Steel | CNC machining, chemical milling | Landing gear, fasteners |

| Nickel-based alloys | CNC machining | Turbine blades, engine high temperature parts |

| Composite Materials | 3D printing, automatic layering | Fuselage shell, wing beam |

| Ceramic Materials | Sintering, precision machining | Thermal barrier coatings, thermal insulation components |

| nylon | Injection molding, 3D printing | Pipe clamps, interior parts |

Of course, other materials are needed, but the above materials have covered most of them, and we at Jeek can process them all.

Advantages of aerospace prototyping

Verify Design Feasibility

In the aerospace field, parts often have complex geometries and strict dimensional requirements. By rapidly manufacturing prototypes, it is possible to test whether the design meets engineering requirements at an early stage, ensure the rationality of the structure, and reduce the cost of subsequent modifications.

Functional Testing and Optimization

The manufactured prototype is not only a display model, but also can be used for wind tunnel testing, mechanical analysis, and material performance evaluation. Through these tests, engineers can optimize the structure of parts, increase strength, reduce weight, and optimize their aerodynamic performance.

Production Process Evaluation

Before mass production, prototype manufacturing can validate the feasibility of different processes, such as CNC machining, 3D printing, sheet metal fabrication, etc., to determine the optimal production method. At the same time, this helps identify potential manufacturing defects, ensuring the final product meets aerospace standards.

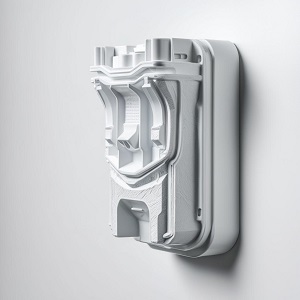

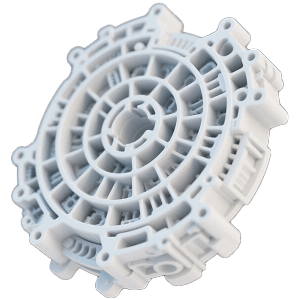

Jeek parts aerospace manufacturing parts

Jeek focuses on the manufacturing of precision components for the aerospace industry, covering categories such as airframe structures, engine parts, instruments, and connectors. In response to the aerospace industry’s stringent requirements for lightweight, high-temperature resistance, corrosion resistance, and high strength, Jeek utilizes manufacturing methods such as CNC machining, 3D printing, and sheet metal fabrication to produce high-precision and stable-performance components.

Whether for prototype validation or mass production, our manufacturing processes meet the strict standards of the aerospace sector. From aluminum alloys and titanium alloys to high-performance engineering plastics, we offer a wide selection of materials. Coupled with surface treatment processes like anodizing, coating, and electroplating, we further enhance the durability and functionality of the components.

More production process options

Frequently Asked Questions

Jeek has been certified with ISO 2015, meeting strict international standards in production and quality management, ensuring high-quality standards and precision manufacturing services for our clients.

Jeek CNC machining services are applicable to multiple industries, such as aerospace, automotive, medical devices, etc. We use high-precision equipment and advanced technology to process complex parts and ensure reliability and performance under extreme working conditions. Our team will develop the most optimized machining solutions based on the special needs of each industry to meet customers’ high standards for precision, quality and delivery.

After completing prototype development, we will conduct functional verification and performance testing to ensure that the design meets expectations. Once confirmed, we will quickly transition to mass production.

Get started quickly

Production of your parts

We ensure that all information provided and uploaded content is kept strictly confidential and secure.