What is Polyethylene (PE)? — Properties, Production, and Main Types

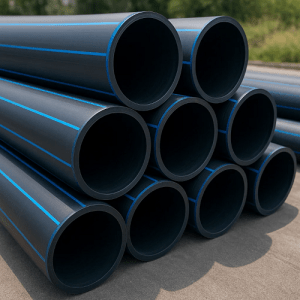

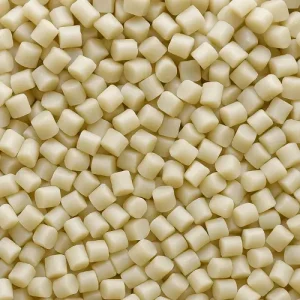

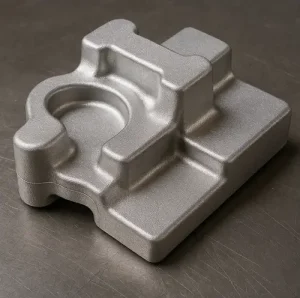

Polyethylene (PE) – a seemingly ordinary but ubiquitous plastic – has long been integrated into every aspect of our lives. From supermarket shopping bags to gas lines, from food packaging to artificial joints, it has become the world’s most widely used plastic material by virtue of its lightweight, strong, corrosion-resistant and low-cost advantages. By adjusting …