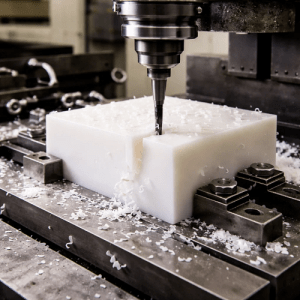

CNC Machining Explained: Machines, Materials, Tolerances, and Practical Engineering Decisions

CNC machining is often described as a cutting process, but in real production, machining results depend on how machines, materials, tolerances, and process planning are handled together. Parts drift out of tolerance, fail inspection, or become unnecessarily expensive not because CNC machining lacks capability, but because these factors are treated in isolation.

On the shop …