We are the Most Dedicated Manufacturer Specializing in Vacuum Brazing Services.

Advanced Vacuum Brazing Services for Medical, Aerospace, Automotive, and Tooling Applications, Etc.

JeekRapid is the most famous CNC Machining Manufacturer In China, While we excel in CNC machining, we are equally confident in our vacuum brazing capabilities. We established our vacuum brazing project department in 2016 and achieved remarkable success in 2018, becoming one of the top ten vacuum brazing factories in China.

We have an experienced team of engineers and a comprehensive product monitoring process. If you are still looking for a reliable and hassle-free vacuum brazing company, then partnering with JeekRapid will be your best choice.

13+ Years

Vacuum Brazing Experience

150M+

Parts Shipped

3600+

Suppliers

Comprehensive

One-stop service

What Is Vacuum Brazing

A metal joining technology performed in a vacuum furnace, where filler metal with a lower melting point than the base metal flows into the joint during heating, achieving a strong bond between parts without melting the parts themselves.

The entire process is carried out in a vacuum environment, effectively avoiding oxidation and contamination, and has very good welding on complex structures and high-precision parts.

Compared with friction stir welding, vacuum brazing achieves high-quality joints through precise process control and metallurgical reactions, making it particularly suitable for precision assemblies, complex structures, and the joining of dissimilar materials.

What Is The Technical advantages of Vacuum Brazing?

- Material Sensitivity: Involves easily oxidized materials such as titanium, aluminum, high-temperature alloys, or dissimilar material combinations.

- Structural Complexity: Requires joining multiple, multi-layered, or internally inaccessible joints in a single operation.

- Stringent Requirements: Demands exceptional levels of airtightness, minimal distortion, high cleanliness, and supreme reliability.

- Pursuit of Efficiency: Aims to achieve stable, scalable production while ensuring top-tier quality.

In essence, vacuum brazing leverages its “solid-state joining” nature and “vacuum-clean” chemical environment to maximally preserve the integrity of base materials while endowing joints with outstanding mechanical and sealing properties. It serves as a critical enabling technology for manufacturing high-performance, highly complex, and ultra-reliable products.

Vacuum Brazing Process Parameters

| Parameter | Value Range |

|---|---|

| Brazing Temperature | 600–1200 °C |

| Vacuum Level | ≤ 5×10⁻³ Pa |

| Heating Rate | 5–20 °C/min |

| Holding Time | 10–60 minutes |

| Cooling Method | Controlled / Inert Gas Cool |

Why Choose Our Vacuum Brazing Services

10+ Years of Proven Vacuum Brazing Experience

With over a decade of hands-on vacuum brazing experience, we have successfully supported a wide range of precision applications across multiple industries. Our long-term process knowledge allows us to consistently deliver stable, repeatable results—even for complex and demanding assemblies.

Precise Control, Stable and Reliable Quality.

Our vacuum brazing process is precisely controlled by experienced engineers, ensuring uniform heating, accurate temperature profiles, and stable metallurgical bonding. This precise control minimizes deformation and prevents oxidation, resulting in clean, high-strength joints with excellent repeatability.

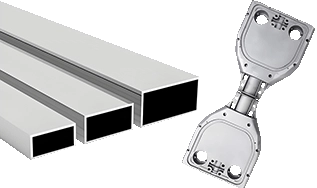

Expertise in Complex and Dissimilar Material Assemblies

We specialize in vacuum brazing complex geometries and dissimilar material combinations, including stainless steels, nickel alloys, copper alloys, and tool steels. Our engineering team carefully evaluates material compatibility and joint design to achieve reliable bonding performance.

Strict Process Control and Quality Assurance

Every vacuum brazing project follows a clearly defined process workflow, from drawing review and material preparation to brazing execution and final inspection. Our quality control measures ensure joint integrity, dimensional stability, and consistent results from prototype to production.

Engineering Support Focused on Your Application

We work closely with our customers’ engineering teams to review designs, optimize joint structures, and recommend suitable brazing solutions. Our goal is not only to manufacture parts, but to help ensure long-term performance in real-world applications.

Trusted by Demanding Industrial Applications

Our vacuum brazing services are trusted by customers in medical, aerospace, automotive, tooling, and industrial equipment sectors—industries where precision, reliability, and quality are non-negotiable.

Materials & lndustries

We provides industrial standard metal and plastic material processing quotations. If you have custom material requirements, please send your request to [email protected] for evaluation by our engineers.

Stainless Steel

The vacuum atmosphere suppresses chromium oxide formation, allowing the brazing filler metal to achieve stable wetting on stainless steel surfaces. This process is well suited for complex assemblies demanding high hermetic integrity and superior corrosion resistance, such as spacecraft propulsion tubing and vacuum system chambers.

Titanium Alloy

Titanium is extremely sensitive to oxygen, nitrogen, and hydrogen at elevated temperatures. Vacuum brazing is the only scalable process that provides a sufficiently clean environment to prevent brittle phase formation and achieve high-strength, high-toughness joints. It is widely used for aero-engine compressor components and biomedical implant frameworks.

High Temperature Alloy

Vacuum brazing typically uses filler metals with compositions similar to the base material (such as nickel-based BNi alloys). During brazing, interdiffusion between the filler and base material forms a metallurgically bonded zone with excellent high-temperature strength, oxidation resistance, and creep resistance. It is a critical process for manufacturing internal cooling channels in turbine blades and combustion chamber components.

Aluminum Alloy

The dense aluminum oxide film on aluminum alloys is the primary barrier to brazing. Vacuum brazing, assisted by active elements such as magnesium, removes this oxide layer in a vacuum environment and promotes filler metal flow. This process is especially suitable for joining thin-walled components with complex flow channels, such as plate-fin heat exchangers and cold plates used in aerospace applications.

Copper Alloy

Oxygen-free copper and similar materials are prone to hydrogen embrittlement in hydrogen atmospheres. Vacuum brazing eliminates this risk and enables the use of low-resistance silver-based filler metals, producing joints with electrical and thermal conductivity close to the base material. It is the preferred joining method for high-power microwave devices, particle accelerator cavities, and high-efficiency heat exchangers.

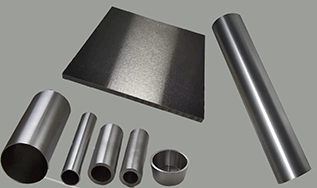

Molybdenum & Tungsten

The vacuum atmosphere suppresses chromium oxide formation, allowing the brazing filler metal to achieve stable wetting on stainless steel surfaces. This process is well suited for complex assemblies demanding high hermetic integrity and superior corrosion resistance, such as spacecraft propulsion tubing and vacuum system chambers.

We provide customized processing services for various industries. If you have custom material requirements, please send your request to [email protected], and our engineers will evaluate it.

Aerospace

The vacuum atmosphere suppresses chromium oxide formation, allowing the brazing filler metal to achieve stable wetting on stainless steel surfaces. This process is well suited for complex assemblies demanding high hermetic integrity and superior corrosion resistance, such as spacecraft propulsion tubing and vacuum system chambers.

Learn More

Automotive

Titanium is extremely sensitive to oxygen, nitrogen, and hydrogen at elevated temperatures. Vacuum brazing is the only scalable process that provides a sufficiently clean environment to prevent brittle phase formation and achieve high-strength, high-toughness joints. It is widely used for aero-engine compressor components and biomedical implant frameworks.

Learn More

Medical Devices

Vacuum brazing typically uses filler metals with compositions similar to the base material (such as nickel-based BNi alloys). During brazing, interdiffusion between the filler and base material forms a metallurgically bonded zone with excellent high-temperature strength, oxidation resistance, and creep resistance. It is a critical process for manufacturing internal cooling channels in turbine blades and combustion chamber components.

Learn More

Industrial Machinery

The dense aluminum oxide film on aluminum alloys is the primary barrier to brazing. Vacuum brazing, assisted by active elements such as magnesium, removes this oxide layer in a vacuum environment and promotes filler metal flow. This process is especially suitable for joining thin-walled components with complex flow channels, such as plate-fin heat exchangers and cold plates used in aerospace applications.

Learn More

Consumer Products

Oxygen-free copper and similar materials are prone to hydrogen embrittlement in hydrogen atmospheres. Vacuum brazing eliminates this risk and enables the use of low-resistance silver-based filler metals, producing joints with electrical and thermal conductivity close to the base material. It is the preferred joining method for high-power microwave devices, particle accelerator cavities, and high-efficiency heat exchangers.

New Energy

The vacuum atmosphere suppresses chromium oxide formation, allowing the brazing filler metal to achieve stable wetting on stainless steel surfaces. This process is well suited for complex assemblies demanding high hermetic integrity and superior corrosion resistance, such as spacecraft propulsion tubing and vacuum system chambers.

Don’t Let Your Designs Stay Only on the Screen. Request a Quote Now and Start Production Today!

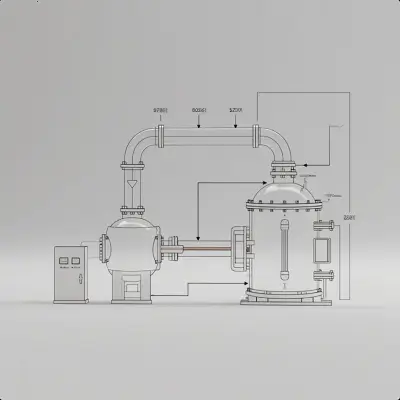

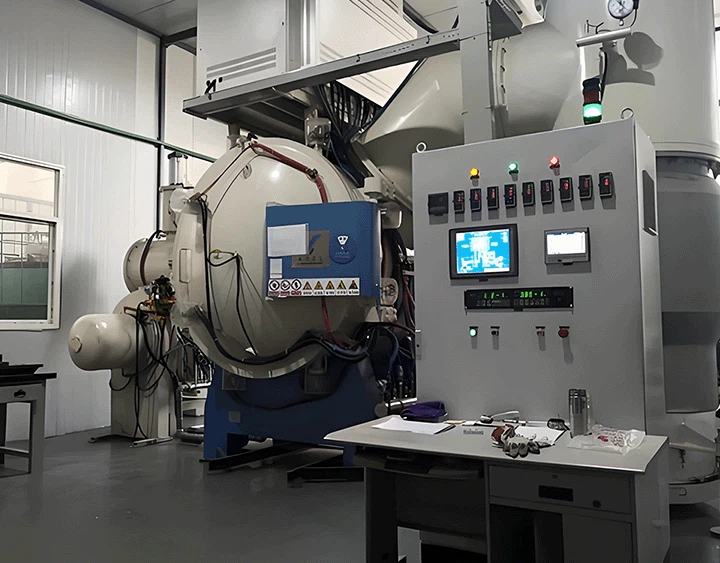

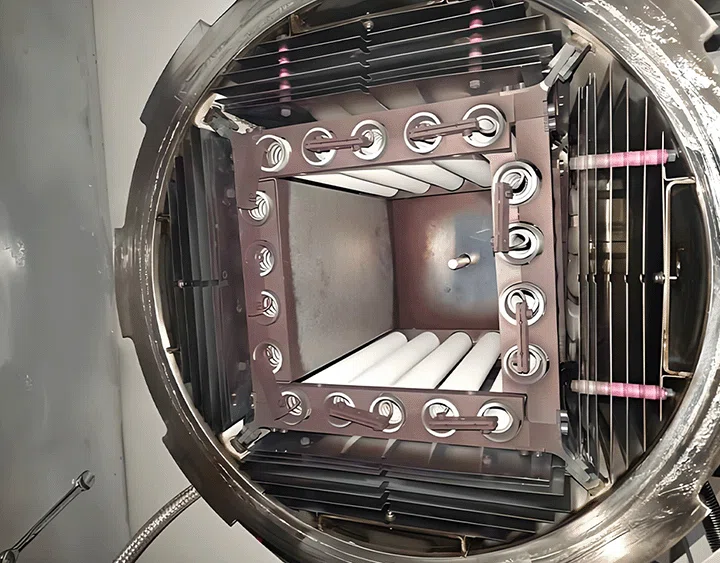

Jeek Brazing Equipment

We are equipped with advanced high vacuum brazing furnaces that support a variety of atmospheres and temperature control programs. The furnace temperature uniformity can reach ±2°C, and it has multi-stage program control and real-time data recording functions to ensure the traceability and consistency of each welding process.

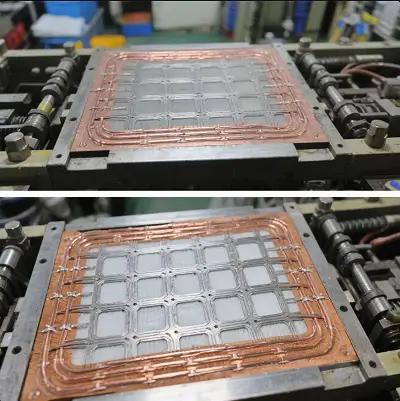

Jeek Customization Capabilities

We can customize welding fixtures and welding process routes according to the drawings or samples provided by customers. Single-piece trial production and small batch proofing can be mass-produced stably, and we can respond flexibly and quickly.

Vacuum Brazing Process

Get started quickly

Production of your parts

We ensure that all information provided and uploaded content is kept strictly confidential and secure.