From initial design to prototyping and full-scale production, Jeek provides high-quality, fast-turnaround manufacturing through CNC machining, injection molding, sheet metal fabrication, metal forming, 3D printing, vacuum casting, surface finishing, welding, and custom manufacturing services—delivering tailored solutions that perfectly fit your project needs.

About Jeek

Jeek is a specialist in high-precision CNC machining and a wide range of manufacturing services including injection molding, custom machining, 3D printing, sheet metal fabrication, metal forming, vacuum casting, surface finishing, and welding. Backed by a team of 60 to 70 experienced technical experts, we are committed to providing innovative, accurate, and efficient manufacturing solutions. Whether you need small batch runs or fully customized parts, Jeek consistently meets and exceeds customer expectations.

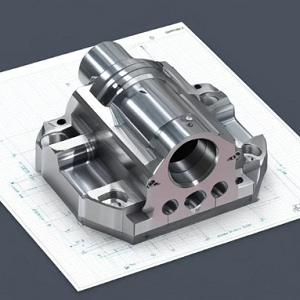

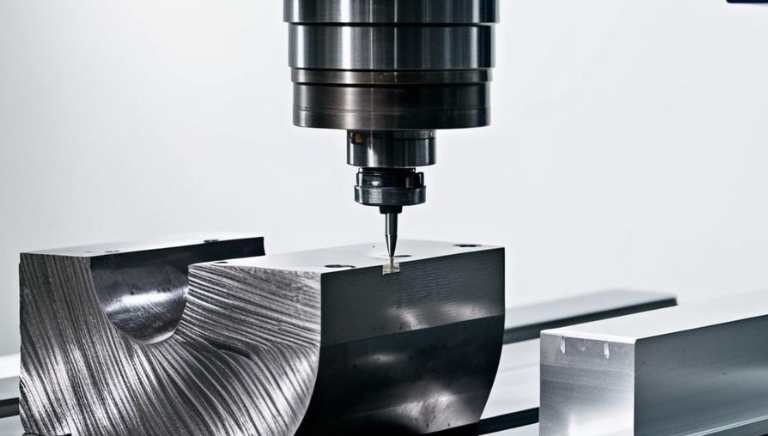

Precise CNC machining technology provides high-quality customized solutions for your project. Click to learn more.

Professional sheet metal fabrication to meet various complex structural needs. Click to see how we can support your project.

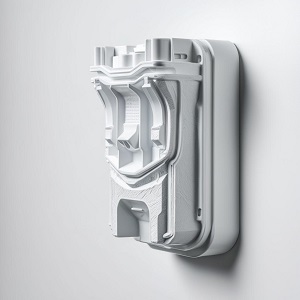

Efficient injection molding technology provides you with precise and stable product production. Click to learn more.

Efficient metal forming process, suitable for the manufacture of high-strength and complex structural parts. Click to learn about our forging, powder metallurgy and other services.

Prototypes

and Parts

7 day standard delivery for simple parts between 5mm x 5mm and 300mm x 300mm. Upload your part to see if it’s eligible.

01

Upload CAD Files

02

Get Quote And Analyze

03

Order Confirmation

04

Shipping Address

Why you can trust Jeek?

We adhere to international ISO standards and are ISO 9001:2015 certified. Every stage of our machining process undergoes strict quality control. Equipped with advanced measurement instruments and equipment, we ensure precise inspection of every detail to maintain high accuracy and consistency. Our technical team is dedicated to providing reliable machining services, ensuring that every project meets the highest quality standards.

Numbers Speak For Themselves!

Real-time quotes

We understand the importance of project schedule and are committed to responding quickly to your needs and providing accurate quotes regardless of the size of your project.

Strict quality control

Jeek consistently follows ISO standards, rigorously controlling every machining step to ensure that every delivered project meets high standards.

High-precision equipment and technology

We are equipped with advanced measuring instruments and high-precision machining equipment to accurately achieve complex designs.

Flexible customization options

We provide tailor-made machining solutions for different industries and needs, catering to personalized requirements.

Our customers

Jeek provides global on-demand production services, and our customer base ranges from independent designers to large enterprises, and is expanding nationwide through word of mouth.

Covering everything from external light sources to various components inside the vehicle.

These range from handheld devices to large medical treatment systems.

Covering everything from precision components to critical structural parts in aircraft and spacecraft.

From discussion to optimization, comprehensive evaluation and verification.

Rapid prototyping to production

Jeek provides a full range of services from rapid prototyping to mass production, helping you to realize your product from concept to implementation in the shortest possible time.

Rapid prototyping

With Jeek, you can prototype in days, quickly validate your ideas and move to the next step of development.

Timely response to quotation

Design optimization feedback

Efficient delivery

Small batch production

Jeek offers flexible low-volume manufacturing to help you quickly move from prototype to mass production.

Accurate production planning

Strict quality inspection

Ensure on-time delivery

Precisely customized solutions

Our team can help you customize every product you need

Tailor-made production solutions

Customized manufacturing services

Full-process customization support

Want to know more about us

Advanced 3D printing brings your ideas into reality with speed and precision, making it ideal for prototypes, complex parts, and flexible low-volume production.

Flexible vacuum casting offers smooth surface finishes and fast turnaround for prototypes and short-run production with excellent material simulation.

Explore insights, manufacturing tips, and the latest updates from Jeek to help you bring better ideas to life.

links: jeek mold