Automotive Prototype Design

Jeek provides precision component manufacturing for the automotive industry, covering areas such as powertrains, body structures, and interior and exterior trims. Relying on advanced processing techniques and strict quality control, the components we produce are strong, lightweight, and durable, ensuring stable performance in various driving environments. Our products meet the automotive industry’s stringent requirements for safety, reliability, and precision.

Jeek provides high-precision component manufacturing for the automotive industry, covering areas such as powertrains, structures, interiors, and exteriors. Through advanced processing techniques, strict quality inspections, and consistent automotive performance, we meet the industry’s stringent requirements, offering reliable support for vehicle research and development production.

Why manufacture

Automotive

using Jeek?

ISO Certification

Jeek is ISO 9001:2015 certified, and its automotive parts production meets international quality standards.

Precision Manufacturing

Adopt advanced technology to process complex automotive parts with high precision.

Diverse Materials

Support a variety of material options such as aluminum alloy, stainless steel, and high-performance plastics.

Fast Delivery

Efficient production process, shortened cycle, to meet the urgent development needs of the automotive industry.

Quality Assurance

Strictly test each part to ensure that the parts meet industry requirements.

Customized Service

Provide a full range of manufacturing solutions from prototyping to mass production.

(Jeek) Transforming car design into reality: efficient prototyping and customization services

At Jeek, we focus on turning automotive designs into physical objects. Whether it is small-batch production or functional verification, we use advanced technologies such as CNC machining and 3D printing to provide fast and efficient parts manufacturing. Our goal is to make every part meet high standards and help your project move forward smoothly.

Automotive prototype manufacturing materials, processes, and applications

Overview of various common automotive component materials, processing techniques, and typical applications.

| Material Type | Processing Technology | Application |

|---|---|---|

| Aluminum | CNC Machining, Stamping | Body panels, Radiator brackets |

| Plastics (ABS, PC) | Injection Molding, 3D Printing | Dashboard prototypes, Interior parts |

| Steel | Welding, CNC Machining | Chassis components, Frames |

| Polyurethane Foam | CNC Cutting, Hand Shaping | Simulated seats, Soft interior parts |

| Carbon Fiber Composites | Hand Lay-up, Prepreg Lay-up | Concept car bodies, Lightweight parts |

Advantages of prototype manufacturing in automotive parts development

Design Verification and Development Efficiency

Rapid prototyping allows engineers to quickly validate designs in the early stages, checking part dimensions, shapes, and assembly to prevent design flaws after mass production, ultimately improving overall development efficiency.

Structural Testing and Performance Optimization

By producing functional prototypes, our Jeek engineering team can conduct multiple tests, including strength, heat resistance, and wear resistance. This process helps optimize material selection and structural design, enhancing component reliability under various working conditions.

Production Feasibility Assessment

Prototyping is not only for design validation but also for evaluating mass production feasibility. It helps assess machining processes, assembly methods, and production costs, providing valuable data for large-scale manufacturing.

Short Lead Time, Faster Time-to-Market

Compared to traditional manufacturing methods, our rapid prototyping process has shorter lead times, allowing quick adaptation to design changes. This accelerates the development of new models or components, reducing time to market.

Low-Cost Trial Production, Reduced Development Risks

Conducting small-batch trial production before mass production helps minimize cost losses due to design or manufacturing issues. It also increases flexibility during the development phase and reduces overall project risks.

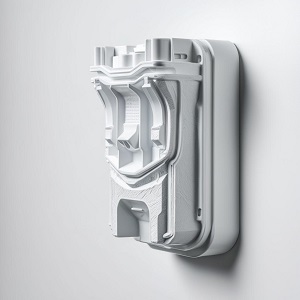

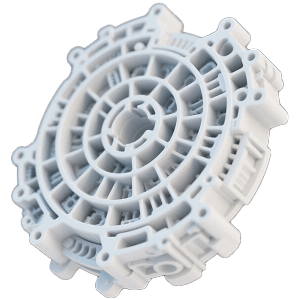

Some auto parts of Jeek

Over the years, we have accumulated a wealth of experience that enables us to meet the challenges of various automotive projects. Below is a display of some of the high-precision automotive parts we provide to customers around the world.

More production process options

Frequently Asked Questions

Jeek is ISO 2015 certified, adhering to strict international standards in production and quality management, providing customers with high-quality standards and precision manufacturing services.

Jeek CNC machining services are applicable to multiple industries, such as aerospace, automotive, medical devices, etc. We use high-precision equipment and advanced technology to process complex parts and ensure reliability and performance under extreme working conditions. Our team will develop the most optimized machining solutions based on the special needs of each industry to meet customers’ high standards for precision, quality and delivery.

After completing prototype development, we will conduct functional verification and performance testing to ensure that the design meets expectations. Once confirmed, we will quickly transition to mass production.

Get started quickly

Production of your parts

We ensure that all information provided and uploaded content is kept strictly confidential and secure.