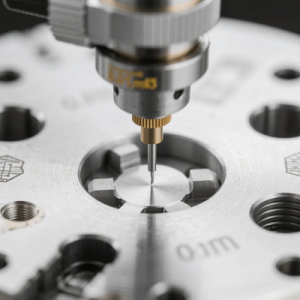

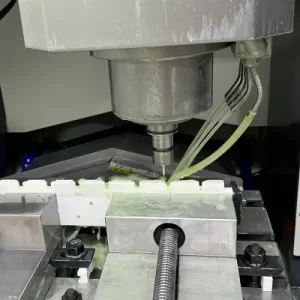

What Is ±0.01mm CNC Machining? Ultra-Precision Metal Parts Explained

In today’s era of miniaturization and high-performance demands, precision is no longer optional but essential. When manufacturing requires extremely tight accuracy, high-precision CNC machining becomes the standard in demanding industries.

This level of precision control means that machining errors must be kept within an extremely small range of 0.02mm — which is critical for the …